A wear-resistant composite liner for a large semi-autogenous mill and its manufacturing method

A semi-autogenous mill and composite liner technology, applied in chemical instruments and methods, grain processing, layered products, etc., can solve the problems of easy cracking, harsh working conditions, short service life, etc., and achieve high impact resistance. and wear resistance, high surface hardening ability, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of large semi-autogenous mill liner

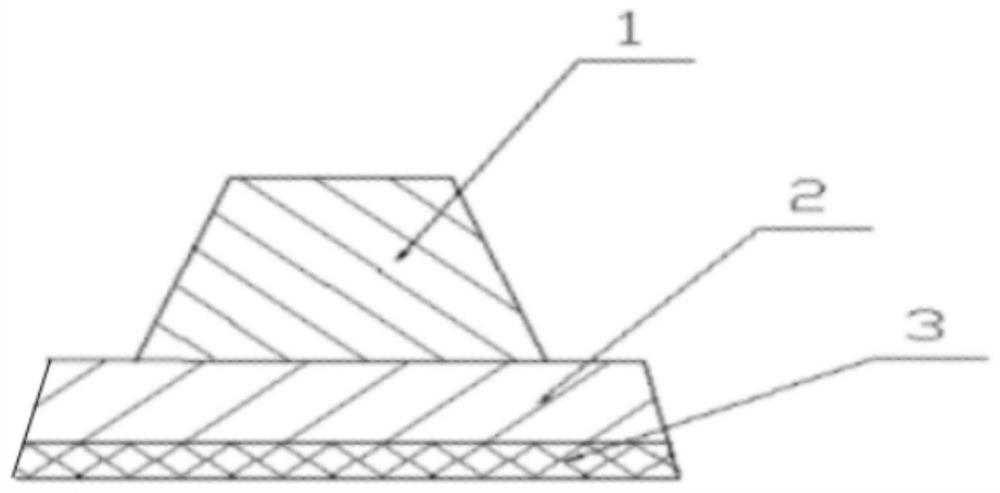

[0032] A wear-resistant composite liner for a large semi-autogenous mill, including a high-strength wear-resistant working part, a high-strength wear-resistant base part and a buffer safety part, one side of the high-strength wear-resistant base part is attached to the buffer safety part and vulcanized by heat Process bonding, the high-strength and wear-resistant working part, the high-strength wear-resistant base part and the buffer security part are connected into one body through high-strength bolts.

[0033] The manufacturing method of large semi-autogenous mill liner comprises the following steps:

[0034] S1 Preparation of high-strength, toughness and wear-resistant working part: Melt molten steel with an intermediate frequency electric furnace, cast it into shape, quench water at 1050 ° C, and then temper at 200 ° C. The high-strength, toughness and wear-resistant working part is a high-strength, toughnes...

Embodiment 2

[0044] Embodiment 2, a kind of large semi-autogenous mill liner

[0045] A wear-resistant composite liner for a large semi-autogenous mill, including a high-strength wear-resistant working part, a high-strength wear-resistant base part and a buffer safety part, one side of the high-strength wear-resistant base part is attached to the buffer safety part and vulcanized by heat Process bonding, the high-strength and wear-resistant working part, the high-strength wear-resistant base part and the buffer security part are connected into one body through high-strength bolts.

[0046] The manufacturing method of large semi-autogenous mill liner comprises the following steps:

[0047] S1 Preparation of high-strength, toughness and wear-resistant working part: Melt molten steel with an intermediate frequency electric furnace, cast it into shape, quench water at 1100 ° C, and then temper at 400 ° C. The high-strength, toughness and wear-resistant working part is a kind of high-strength, ...

Embodiment 3

[0057] Embodiment 3, a kind of large semi-autogenous mill liner

[0058] A wear-resistant composite liner for a large semi-autogenous mill, including a high-strength wear-resistant working part, a high-strength wear-resistant base part and a buffer safety part, one side of the high-strength wear-resistant base part is attached to the buffer safety part and vulcanized by heat Process bonding, the high-strength and wear-resistant working part, the high-strength wear-resistant base part and the buffer security part are connected into one body through high-strength bolts.

[0059] The manufacturing method of large semi-autogenous mill liner comprises the following steps:

[0060] S1 Preparation of high-strength, toughness and wear-resistant working part: Melt molten steel with an intermediate frequency electric furnace, cast it into shape, quench water at 1100°C, and then temper at 400°C. The high-strength, toughness and wear-resistant working part is a high-strength, toughness, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com