High-flatness cigarette case production process

A production process and flatness technology, applied in the production process field, can solve the problems of low tension of the cigarette case conveyor belt, inability to adjust at any time, and affecting the smoothness of the appearance of the cigarette case.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

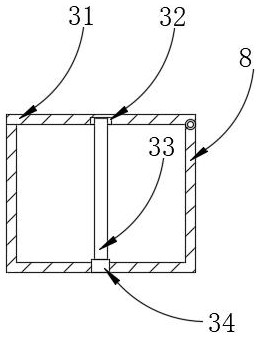

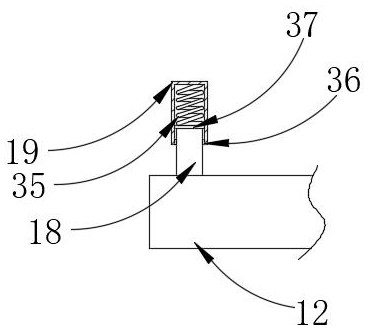

[0024] see Figure 1~5, the present invention relates to a high-flatness cigarette case production process, said process is based on a high-efficiency production line for high-quality cigarette cases, including a support plate 6, the upper surface of the support plate 6 is symmetrically provided with two first chute 10, The inner side walls of the two first chute 10s are slidingly connected with plate bodies 16, and the repelling surfaces of the two plate bodies 16 are equidistantly arranged with threaded holes 15, and the front surface and the rear surface of the supporting plate 6 are threadedly connected with bolts. 38. The adjacent ends of the two bolts 38 are screwed to the inner wall of the threaded hole 15, the adjacent surfaces of the two plate bodies 16 and the upper surface of the support plate 6 are welded with the first U-shaped plate 11, and the two second The outer side wall of a U-shaped plate 11 is symmetrically provided with two second chute 14, the inner side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com