AO combined enhanced nitrogen and carbon removal device with built-in MBR

A denitrification and inner cavity technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effects of increasing sludge return flow, improving aeration efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

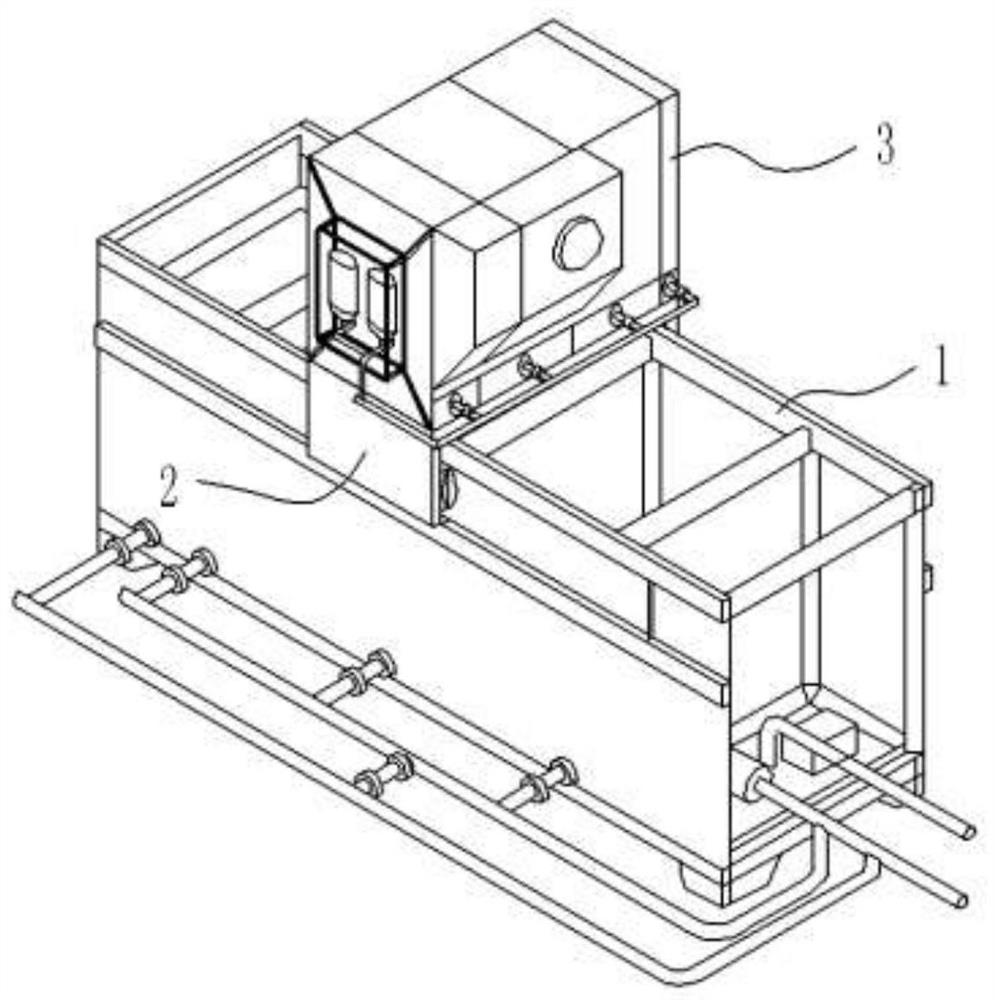

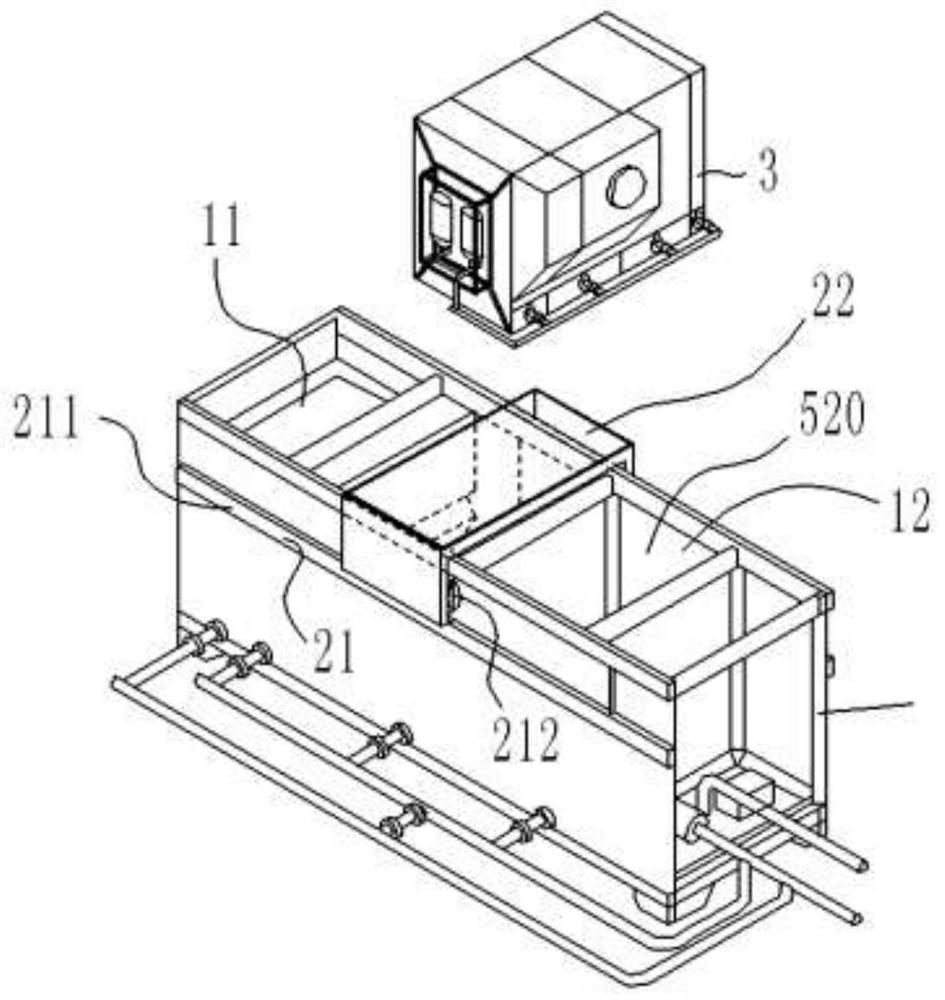

[0026] Embodiment 1: as figure 1 , 2 The AO combination enhanced denitrification and carbon removal device with built-in MBR is shown, including a box body, and a pretreatment unit is set inside the box body for pre-treatment of wastewater, and is set inside the box body to treat the pretreatment unit. The advanced treatment unit for reprocessing wastewater; the box body includes a first installation box 1, a mobile installation part 2 installed on the first box body 1, and a second mobile installation part 2 installed on the first box body 1 Box 3;

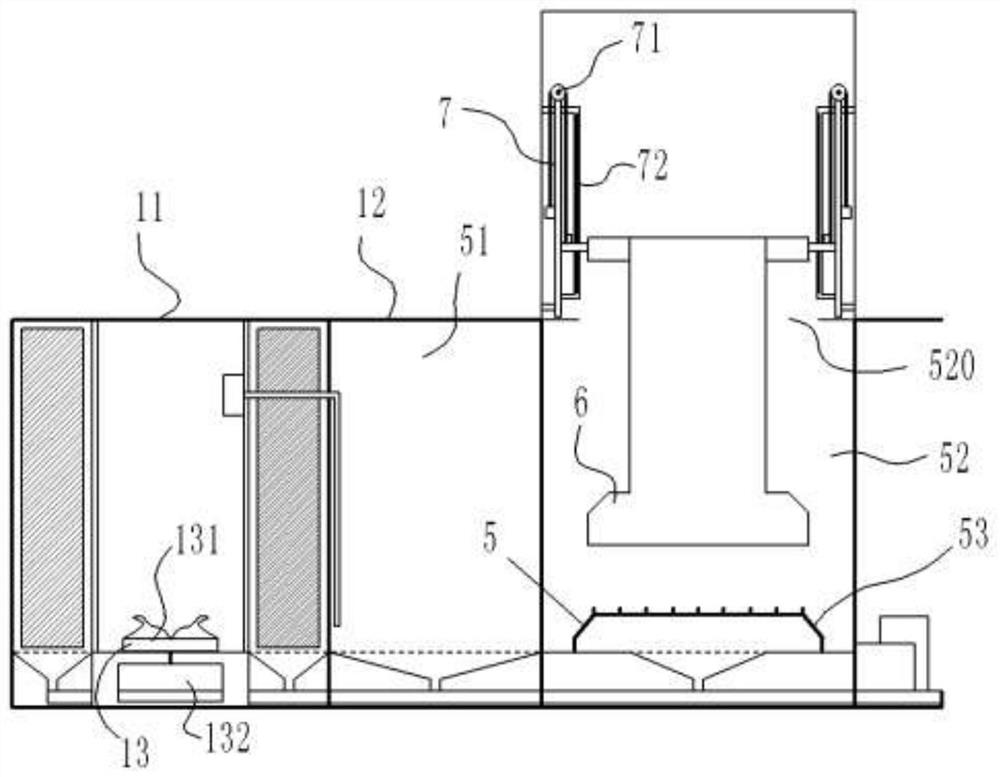

[0027] Such as image 3 As shown, the first box 1 includes a pretreatment chamber 11 and an AO treatment chamber 12 connected in sequence;

[0028] Such as Figure 4 As shown, the pretreatment unit is arranged in the pretreatment chamber 11; the pretreatment unit includes a partition cylinder 41 installed in the pretreatment chamber 11, and a mounting plate for installing the partition cylinder 41 on the inner wall of the pre...

Embodiment 2

[0036] Embodiment 2: The difference from Embodiment 1 is that the first filter cavity 113, the second filter cavity 114, the third filter cavity 115, the fourth filter cavity 116, and the inner cavity 111 are connected in sequence, and the connecting points are respectively provided with first Filter, second filter, third filter, fourth filter; the aperture ratio of the first filter, second filter, third filter, and fourth filter is 3:2:1:0.8 .

Embodiment 3

[0037] Embodiment 3: different from Embodiment 1: as Figure 6 As shown, the chain lifting mechanism 71 includes a mounting rod 711 installed on the side wall of the second box body 3, a chain shaft 712 that is movably arranged on the upper end of the mounting rod 711, a power mechanism 713 installed on the mounting rod 711, and one end is fixedly installed on the On the power mechanism 713, the other end passes through the chain 714 of the chain shaft 712; the mounting part 72 includes a sliding frame 721 installed on the outside of the mounting bar 711, and a fixed frame 722 movably installed on the sliding frame 721; the other end of the chain 714 is fixed On the fixed frame 722.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com