Sinking type vertical shaft heading machine and well forming method thereof

A technology for roadheaders and shafts, which is applied to shaft equipment, well sinking, earthwork drilling, etc., can solve the problems of incompatibility with environmental pollution, ground subsidence and construction space, low degree of mechanization, and slow well completion speed, and achieves high construction efficiency. , high safety, fast excavation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make it easier to understand the technical means, creative features, goals and effects realized by the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely below in conjunction with the embodiments of the present invention and the accompanying drawings. The embodiments described above are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

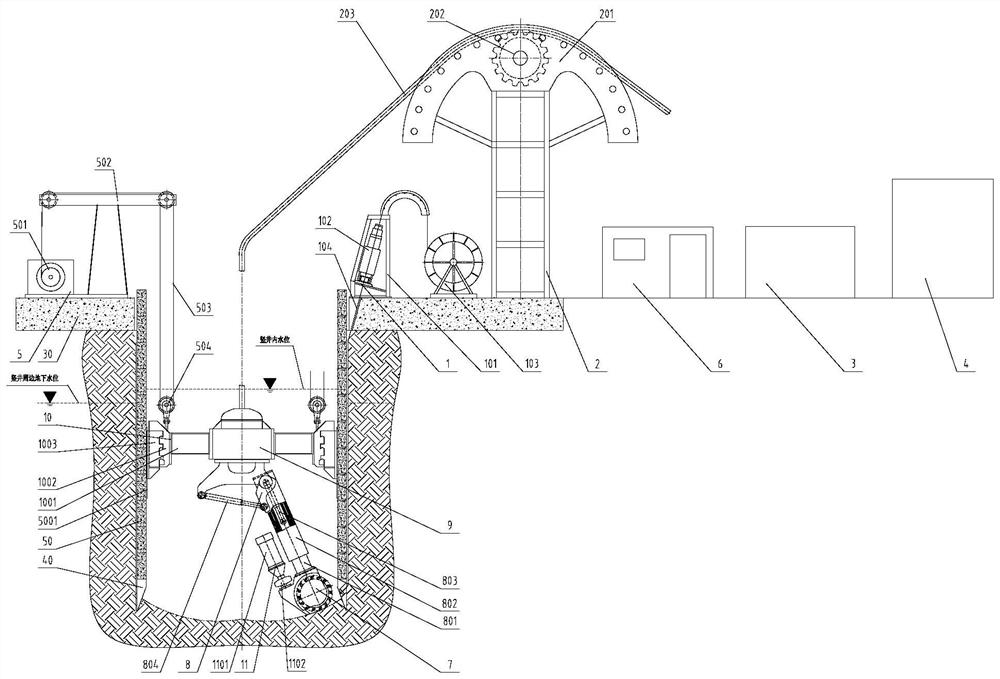

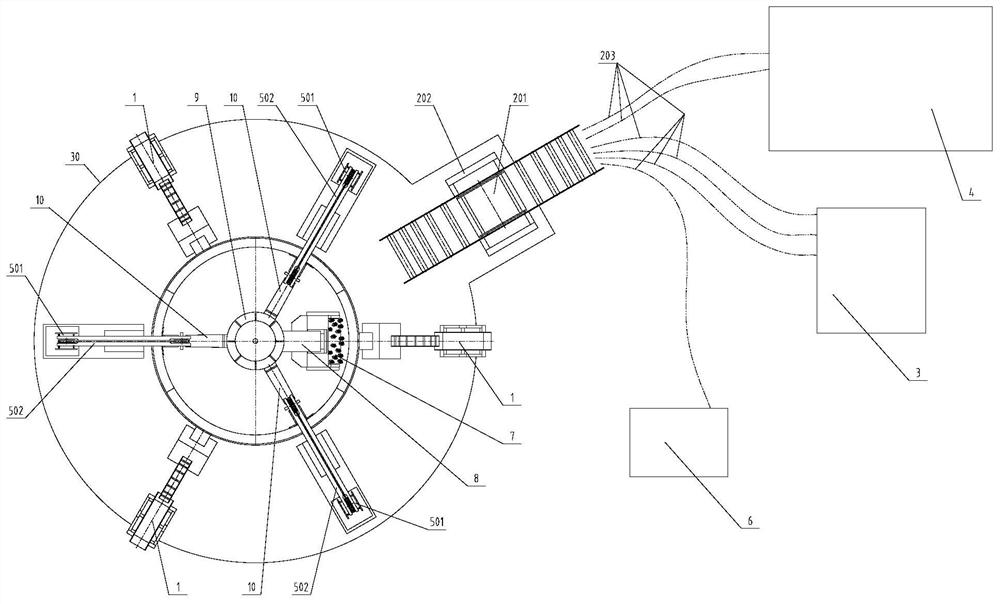

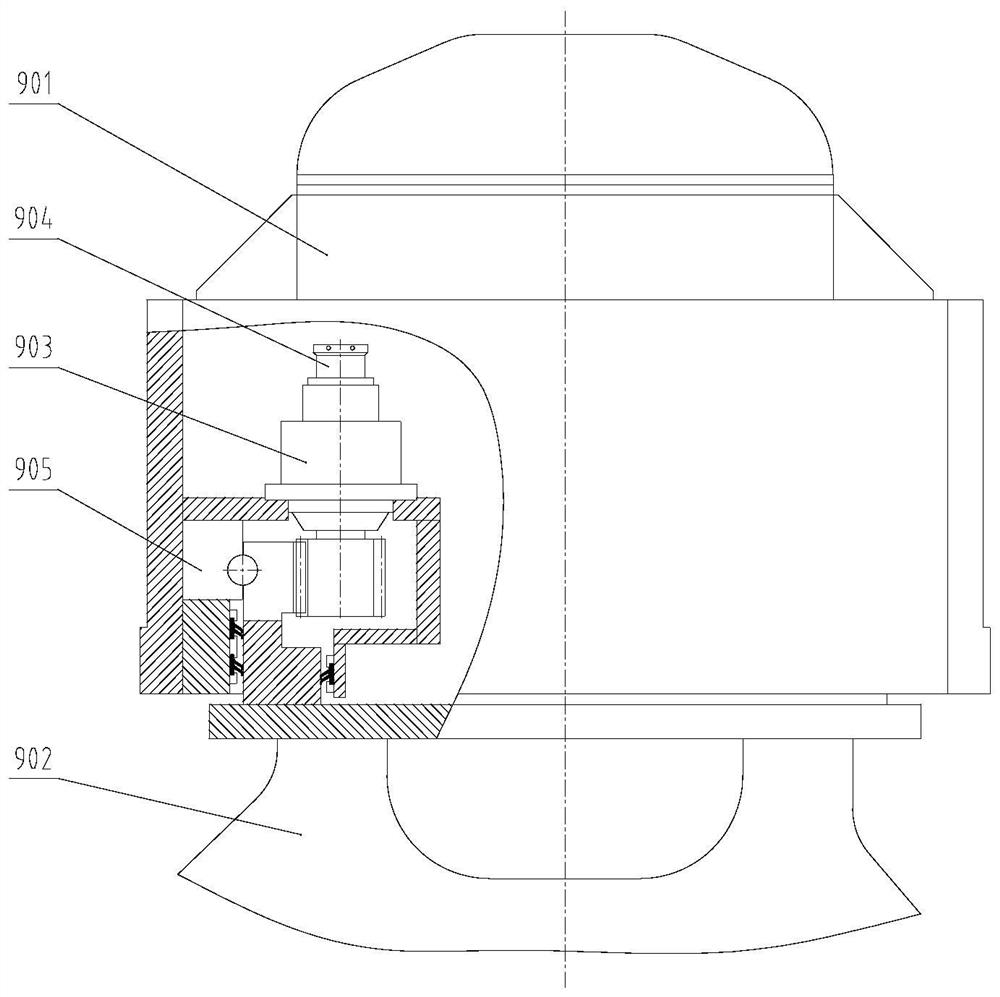

[0033] like Figure 1-3 As shown, a preferred embodiment of the present invention provides a submerged shaft boring machine, including a main engine, a subsidence system 1, a pipeline system 2, a hydraulic station 3, a mud water treatment system 4, a main engine recovery system 5 and a control unit 6 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com