Hydraulic shock absorber with supporting function

A hydraulic shock absorber and functional technology, applied in the field of hydraulic shock absorbers, can solve the problems of hydraulic shock absorbers that cannot be locked, reduce operation accuracy, and safety hazards, and achieve simple structure, reduce safety hazards, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

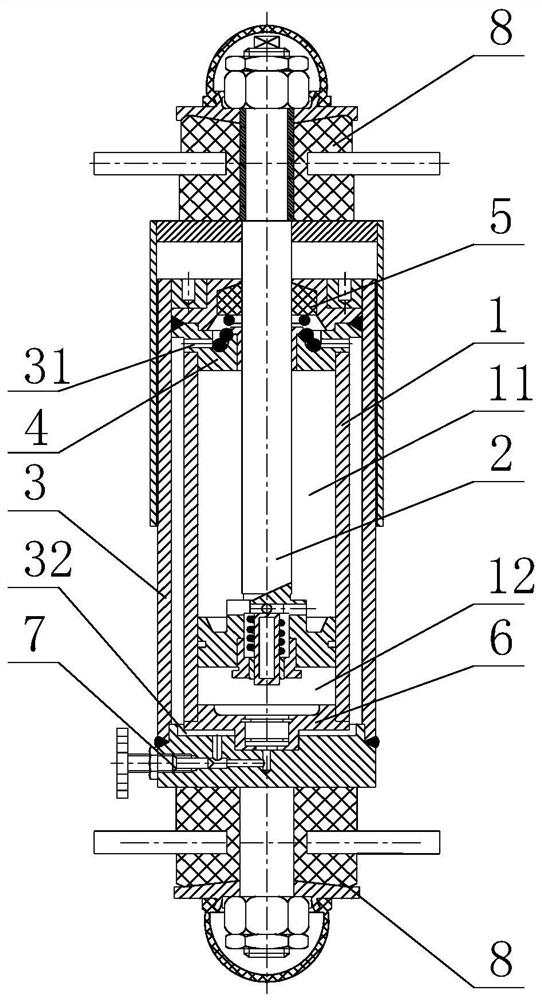

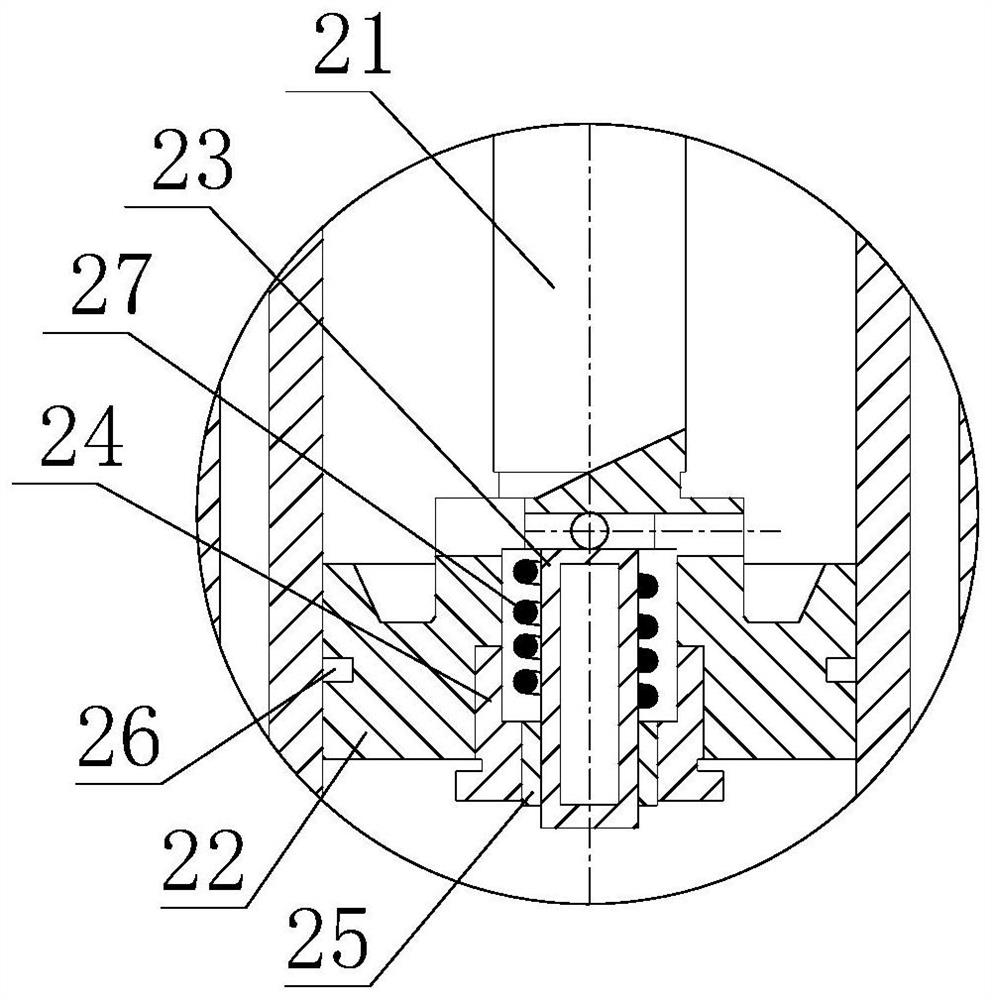

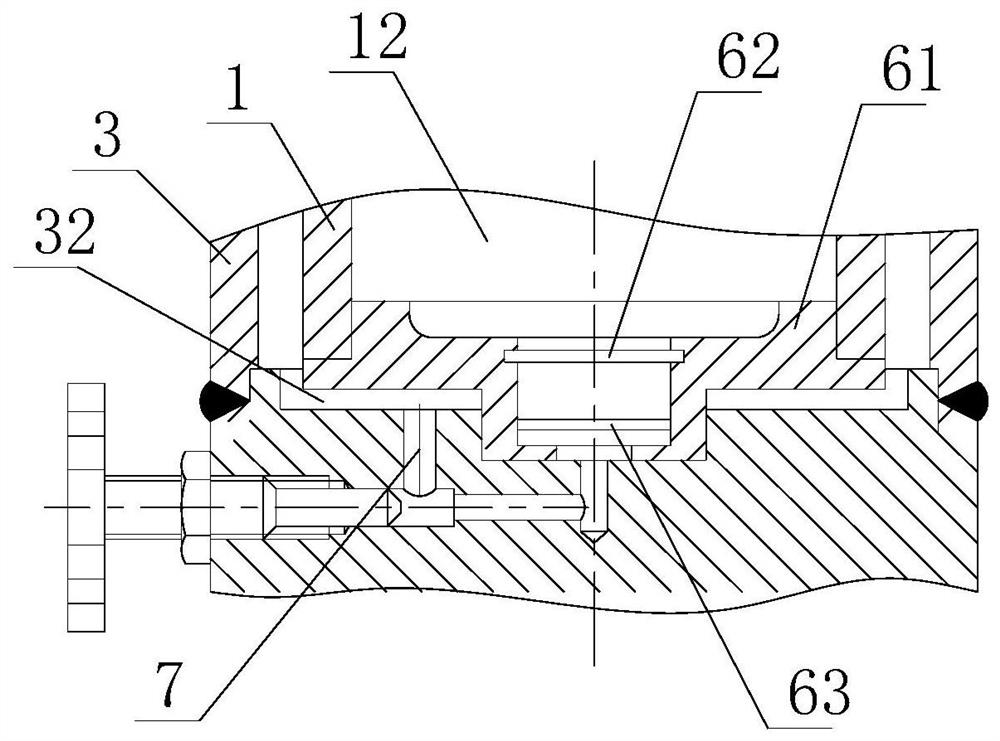

[0036] see figure 1 As shown, the embodiment of the present invention provides a hydraulic shock absorber with support function, including a cylinder 1, a piston assembly 2 is arranged inside the cylinder 1, and the piston assembly 2 divides the interior of the cylinder 1 into a rod cavity 11 and a Rodless chamber 12; cylinder 1 is provided with an oil storage tube 3; cylinder 1 upper end is provided with a cylinder end 4, and cylinder end 4 has an oil return hole 31 communicating with the oil storage tube 3; cylinder 1 lower end is provided with an inlet Oil valve assembly 7, the lower end of oil storage cylinder 3 is provided with passage 32 connected with oil inlet valve assembly 7; due. When the stop valve is opened, the shock absorber acts as a shock absorber; when the stop valve is closed, the two ends of the piston are equivalent to forming a closed cavity, and the piston rod cannot move, forming a support function. At this time, the shock absorber acts as a support de...

Embodiment 2

[0042] see Figure 6 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the coupling assembly 8 is in the form of a pin connection, including a pin seat 810 and a pin 811 .

Embodiment 3

[0044] see Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the coupling assembly 8 is in the form of bolted connection, including a bolt seat 820 and a bolt 821 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com