Modular efficient heat tracing pipe

A heat tracing tube and modular technology, which is applied in the direction of pipe components, piping systems, and pipe heating/cooling, etc., can solve the problems of long manufacturing cycle of jacketed tube heat tracing, high installation and maintenance difficulty, and low external heat tracing efficiency. , to achieve the effect of convenient leak detection and maintenance, easy installation and disassembly, and reduction of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

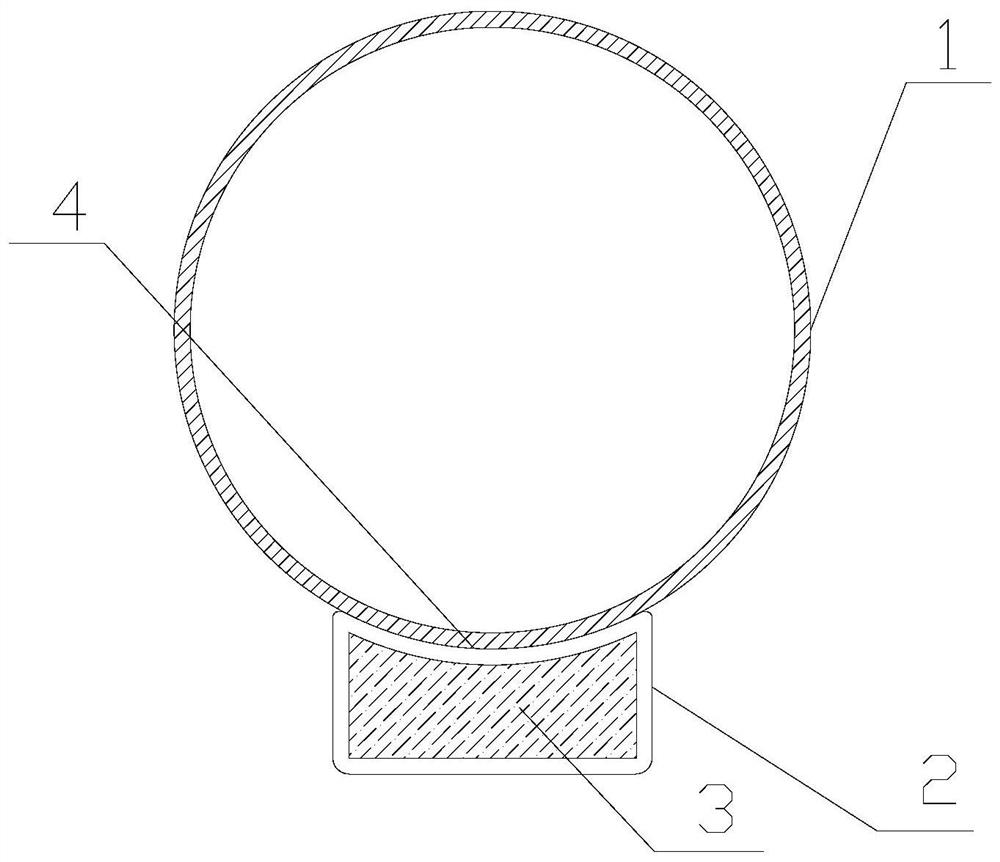

[0022] A modular high-efficiency heat tracing pipe provided in this example, the cross-sectional schematic diagram is as follows figure 1 . In this embodiment, the heat tracing pipe 2 is a square pipe, and one end of the heat tracing pipe 2 matches the shape of the heated part 1. The thermal conductivity of the thermally conductive material is greater than 10W / (m·K). According to the physical properties of the heat tracing medium, operating conditions, and environmental conditions, one or more heat tracing pipes are fixed on the heat tracing pipe to ensure that the heat tracing meets the process requirements.

[0023] In the existing external heat tracing, there is air between the heat tracing pipe 2 and the heated part 1, and the heat transfer is mainly by air convection, and the heat transfer efficiency is low. In this embodiment, the heat tracing pipe 2 matches the shape of the heated part 1, and the soft heat conducting material filled in the joint can squeeze out the ai...

Embodiment 2

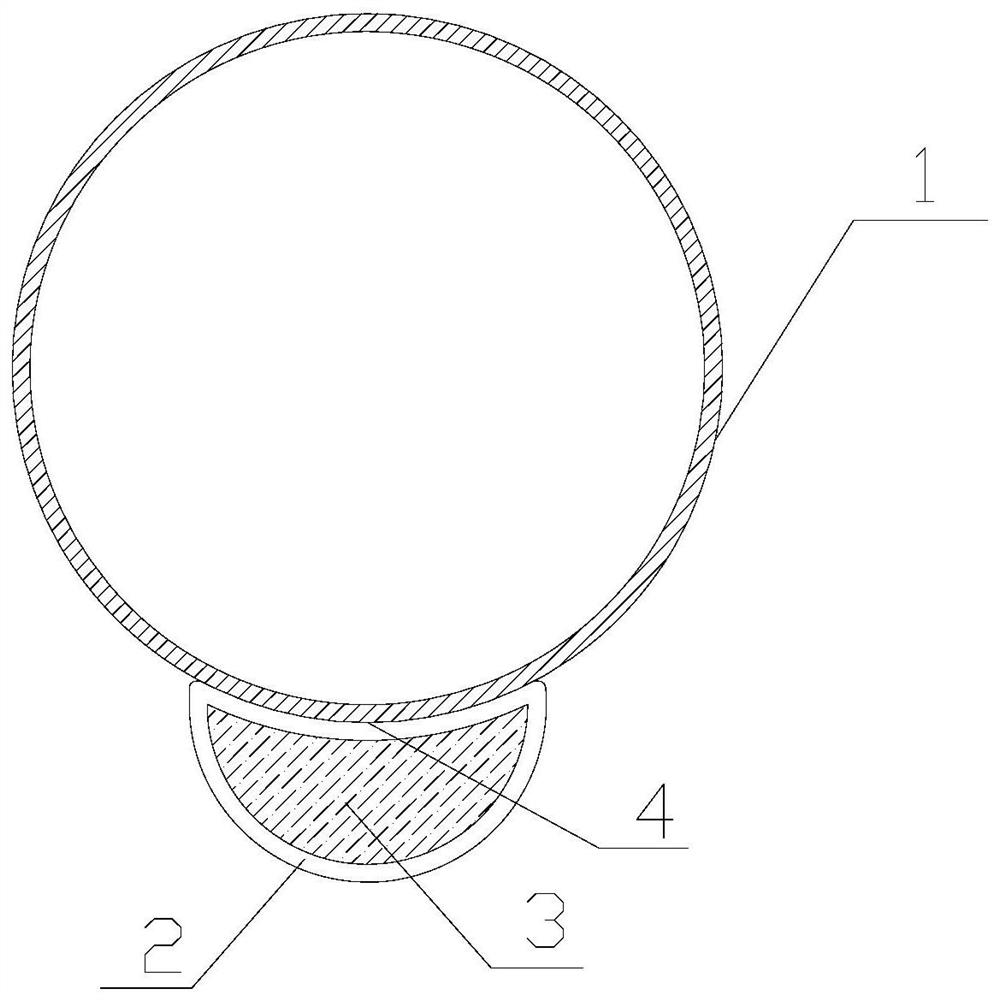

[0025] A modular heating unit provided in this example, the cross-sectional schematic diagram is as follows figure 2 . In this embodiment, the heat tracing pipe 2 is a semicircular pipe, and one end of the heat tracing pipe 2 matches the shape of the heated part 1. The thermal conductivity of the thermally conductive material is greater than 10W / (m·K). According to the physical properties of the heat tracing medium, operating conditions, and environmental conditions, one or more heat tracing pipes are fixed on the heat tracing pipe to ensure that the heat tracing meets the process requirements.

[0026] In the existing external heat tracing, there is air between the heat tracing pipe 2 and the heated part 1, and the heat transfer is mainly by air convection, and the heat transfer efficiency is low. In this embodiment, the heat tracing pipe 2 matches the shape of the heated part 1, and the soft heat conducting material filled in the joint can squeeze out the air, and the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com