Battery cooling system and battery cooling control method

A cooling system and cooling control technology, applied in battery/fuel cell control devices, secondary batteries, electric vehicle charging technology, etc., can solve low cooling efficiency, leakage of coolant in the battery pack, low safety of battery pack operation, etc. problems, achieve high safety, uniform and efficient cooling effect, and improve the effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

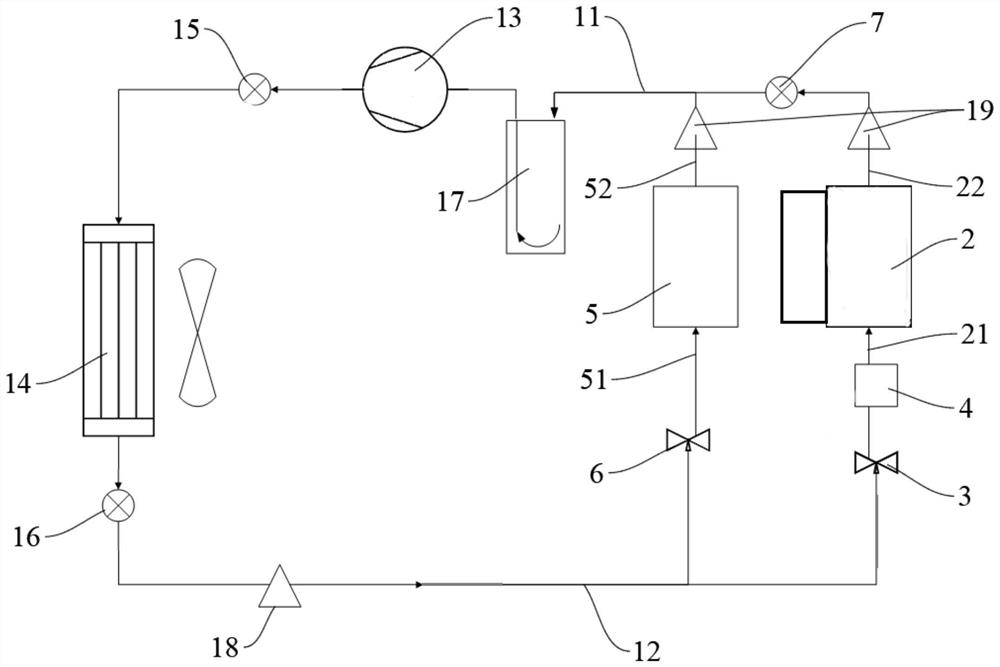

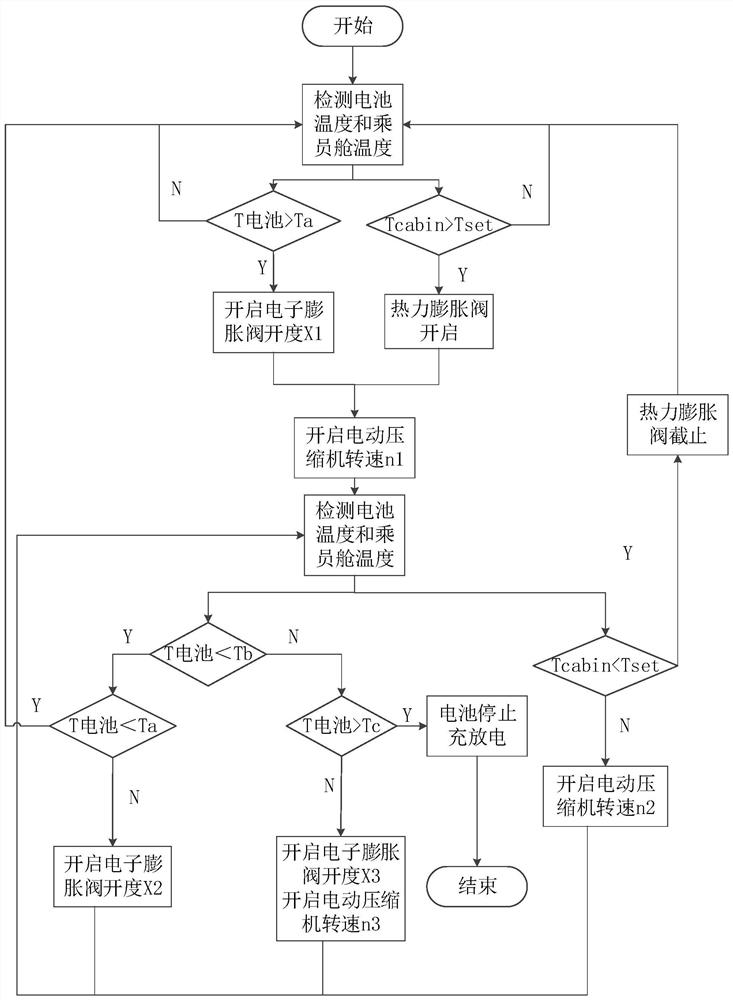

[0054] Refer below Figure 1-Figure 3 A battery cooling system and a battery cooling control method according to a specific embodiment of the present invention are described.

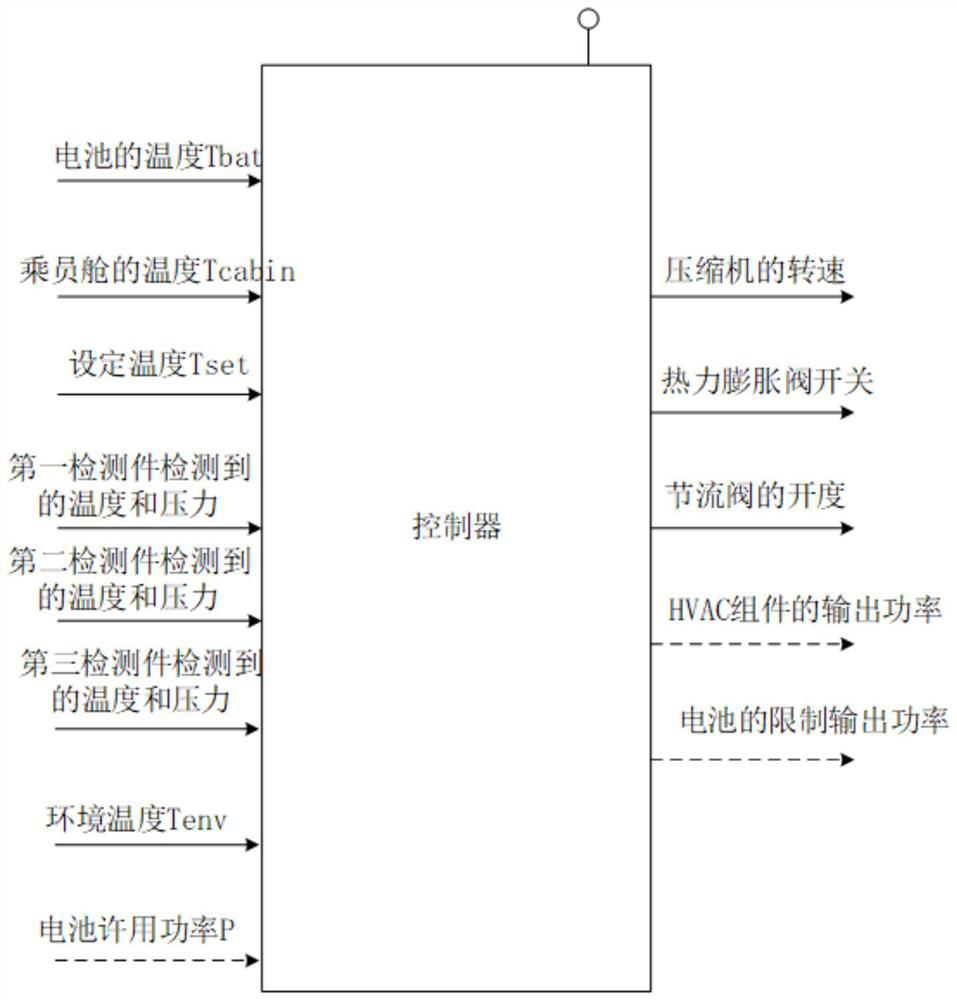

[0055] The battery cooling system of this embodiment includes a refrigeration circuit, a cooling element 2 , a throttle valve 3 , an observation element 4 , an HVAC component 5 , a thermal expansion valve 6 with a cut-off function, a controller, and a third detection element 7 .

[0056] Refrigerant flows through the refrigeration circuit, and the refrigeration circuit has a first inlet 11 and a first outlet 12 . The refrigeration circuit includes a compressor 13 , a condenser 14 , a first detection part 15 , a second detection part 16 , a liquid-gas separation part 17 , a high-pressure charging valve 18 and a low-pressure charging valve 19 . The first inlet 11 communicates with a compressor 13 . One end of the condenser 14 communicates with the compressor 13 , and the other end communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com