Low-noise and high-shielding-coefficient iron-based amorphous material electromagnetic shielding barrel

An iron-based amorphous and shielding coefficient technology is applied in the field of magnetic shielding technology of the present invention to achieve the effects of low noise and high shielding coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

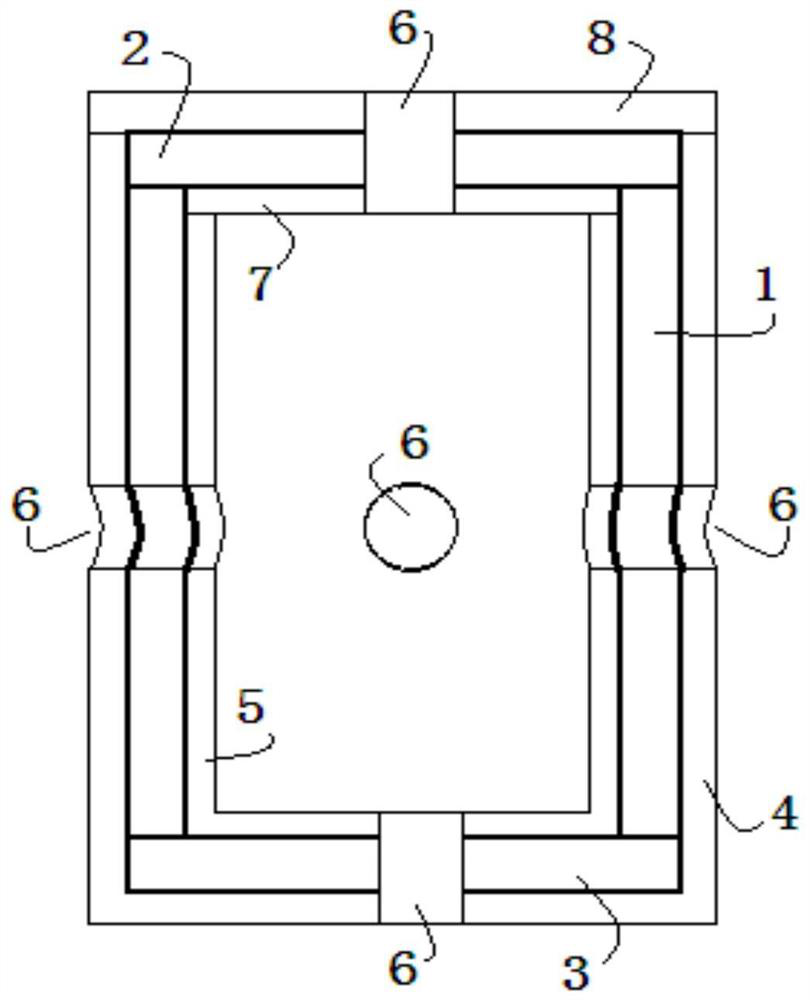

[0017] Below with the accompanying drawings ( figure 1 ) to illustrate the present invention.

[0018] figure 1 It is a structural schematic diagram of an iron-based amorphous material electromagnetic shielding bucket implementing the present invention with low noise and high shielding factor. refer to figure 1 As shown, an iron-based amorphous material electromagnetic shielding barrel with low noise and high shielding coefficient, the iron-based amorphous material barrel body 1, the iron-based amorphous material upper cover 2 and the iron-based amorphous material are formed by using the iron-based amorphous material The electromagnetic shielding barrel combination of the material lower cover 3, the main component of the iron-based amorphous material has the following chemical formula Fe x Si y B 1-X-Y , x=0.5~0.95, y=0.5~0.05. The relative magnetic permeability of the iron-based amorphous material is as high as 450,000 (ratio to vacuum magnetic permeability). The iron-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com