Manufacturing and processing technology of air compressor

An air compressor and processing technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of easy deviation, large gap weld seam quality, clamping object depression, etc., to improve the connection tightness , increase the fit area, improve the effect of fixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

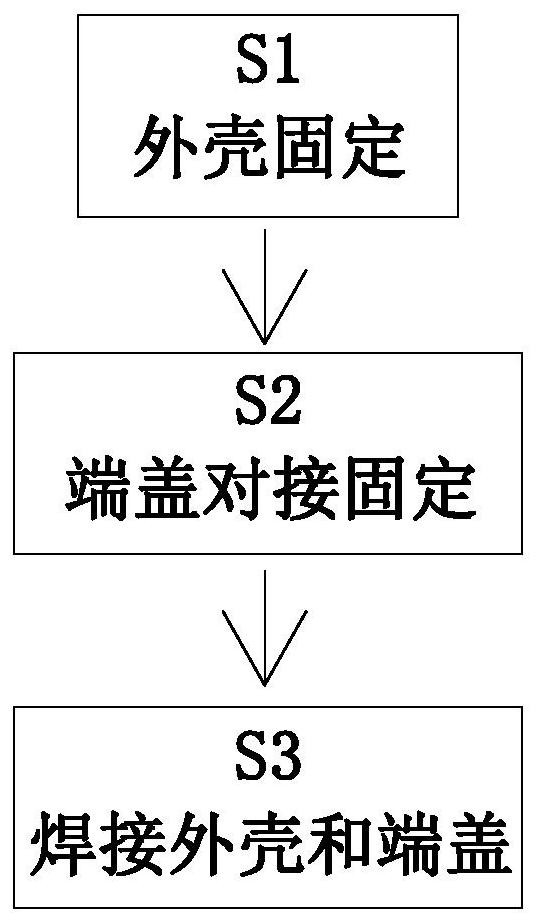

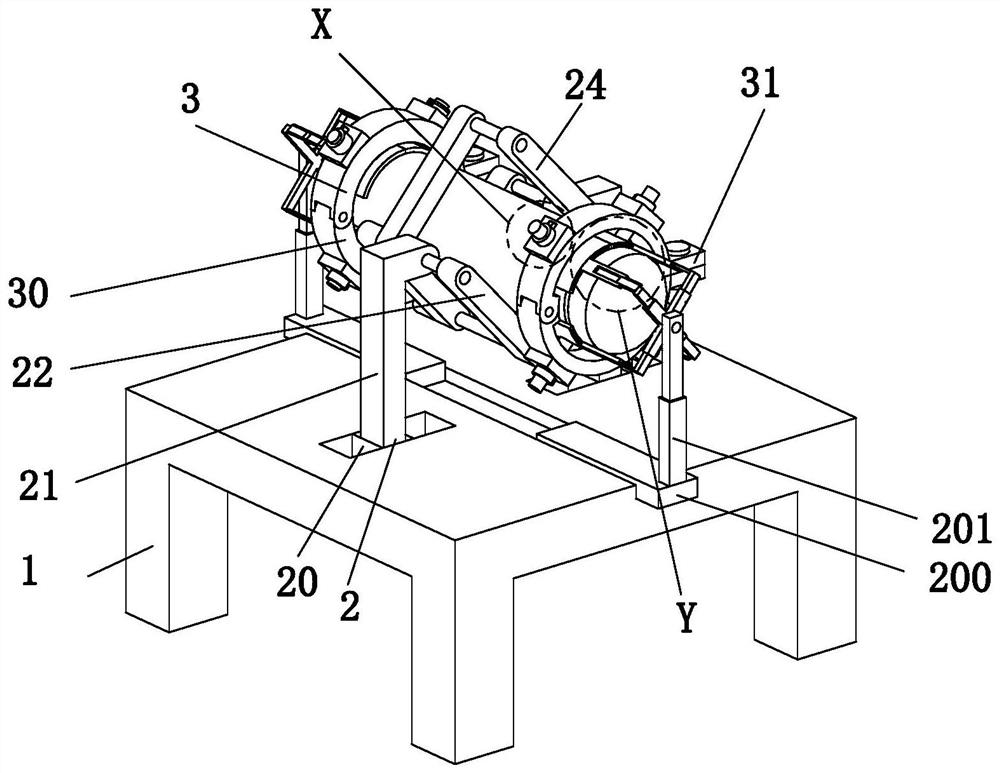

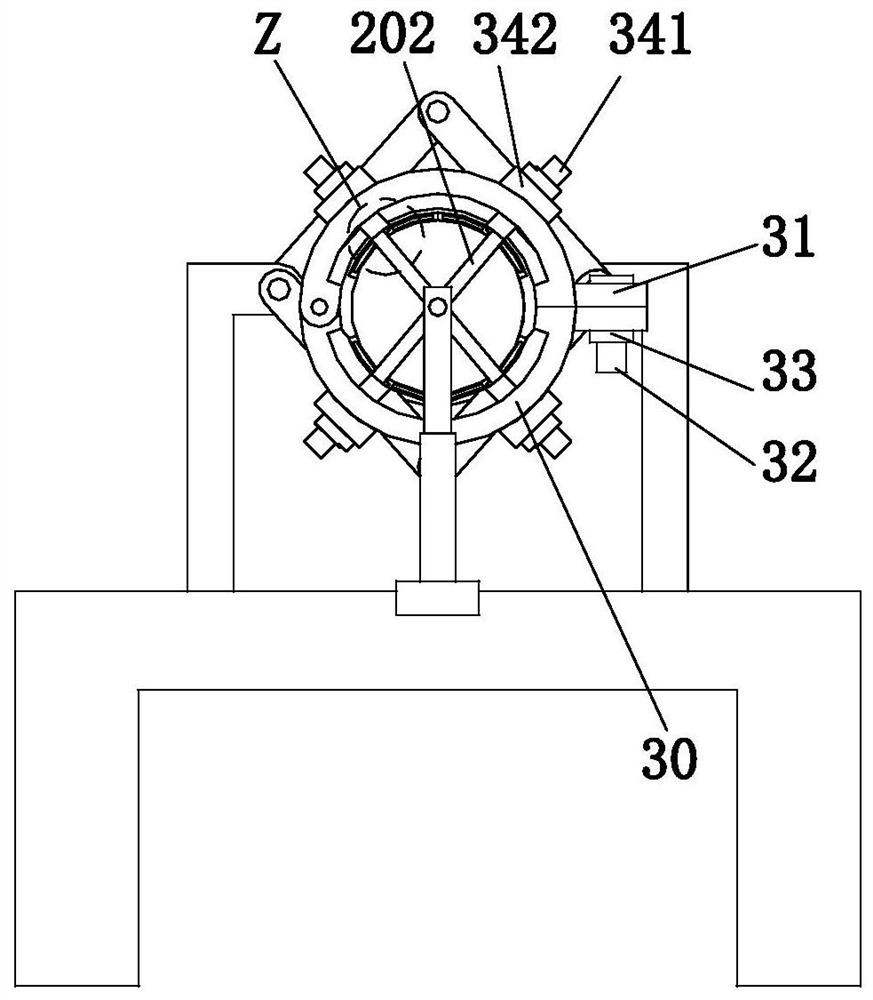

[0037] Such as Figure 1 to Figure 11 Shown is an air compressor manufacturing process, which uses an air compressor manufacturing and processing device, which includes a workbench 1, a main clamping mechanism 2 and an auxiliary welding mechanism 3, and is manufactured The specific processing technology of the processing device for air compressor manufacturing and processing is as follows:

[0038] S1. Shell fixing: manually place the shell between the No. 1 splint 22 and the No. 2 splint 23, and then drive the inverted L-shaped frame 21 to move in the opposite direction through the No. 1 electric slider 20, and the No. 1 splint 22 and the No. 2 splint 23 Pulled synchronously to the outside, the upper splint 24 makes a synchronous outward expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com