Valve body processing technology and processing equipment

A technology for processing equipment and valve bodies, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low cleaning efficiency and poor cleaning effect, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

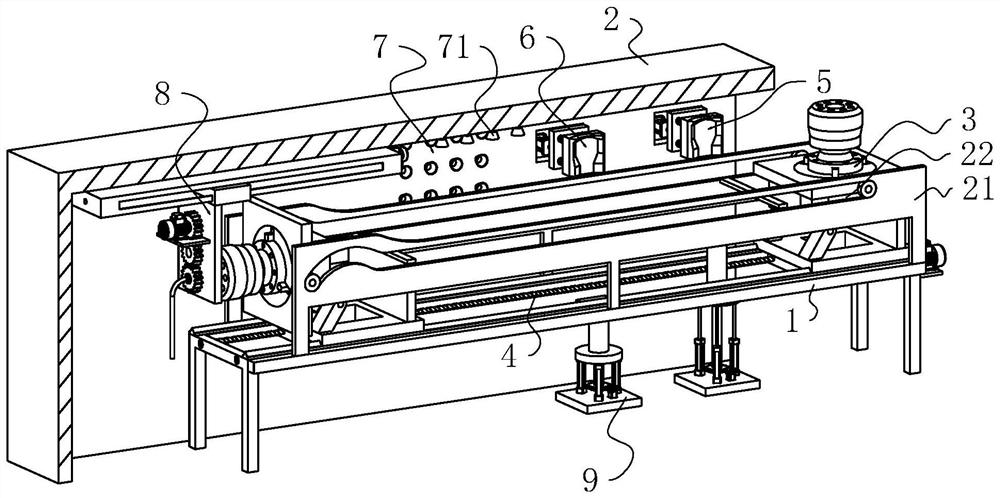

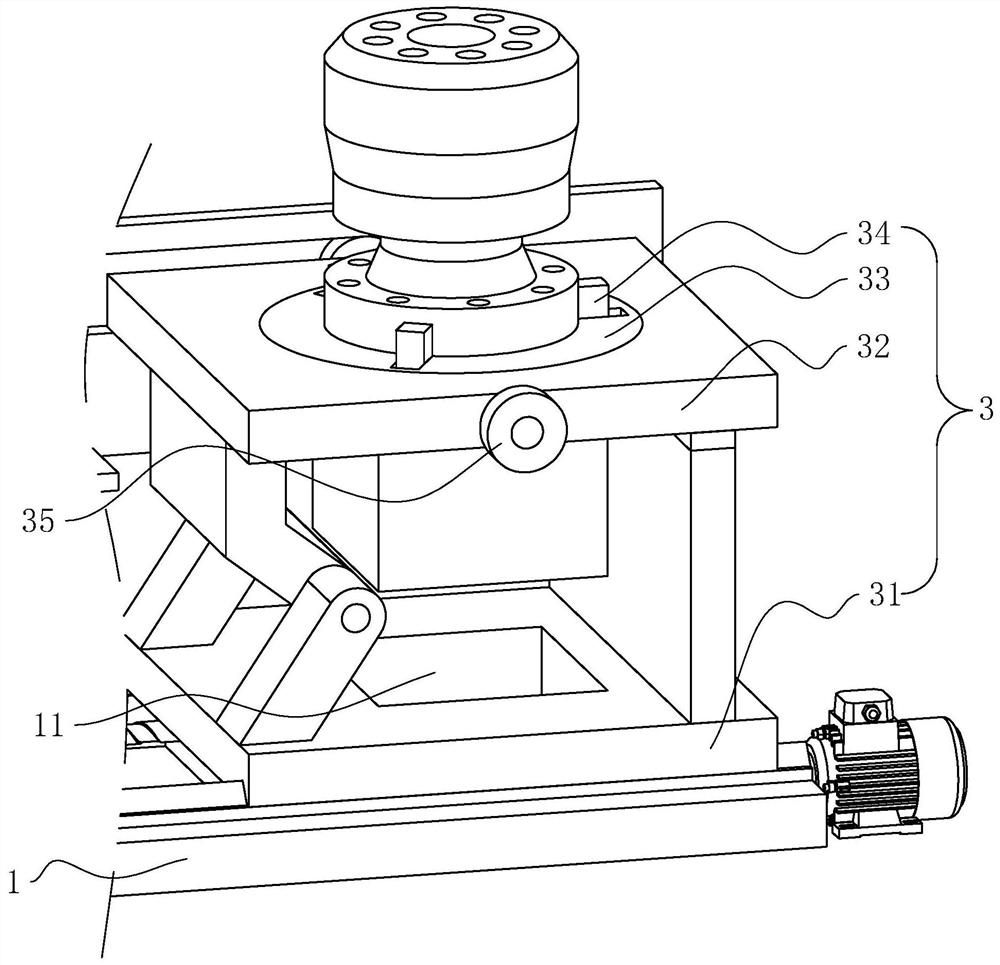

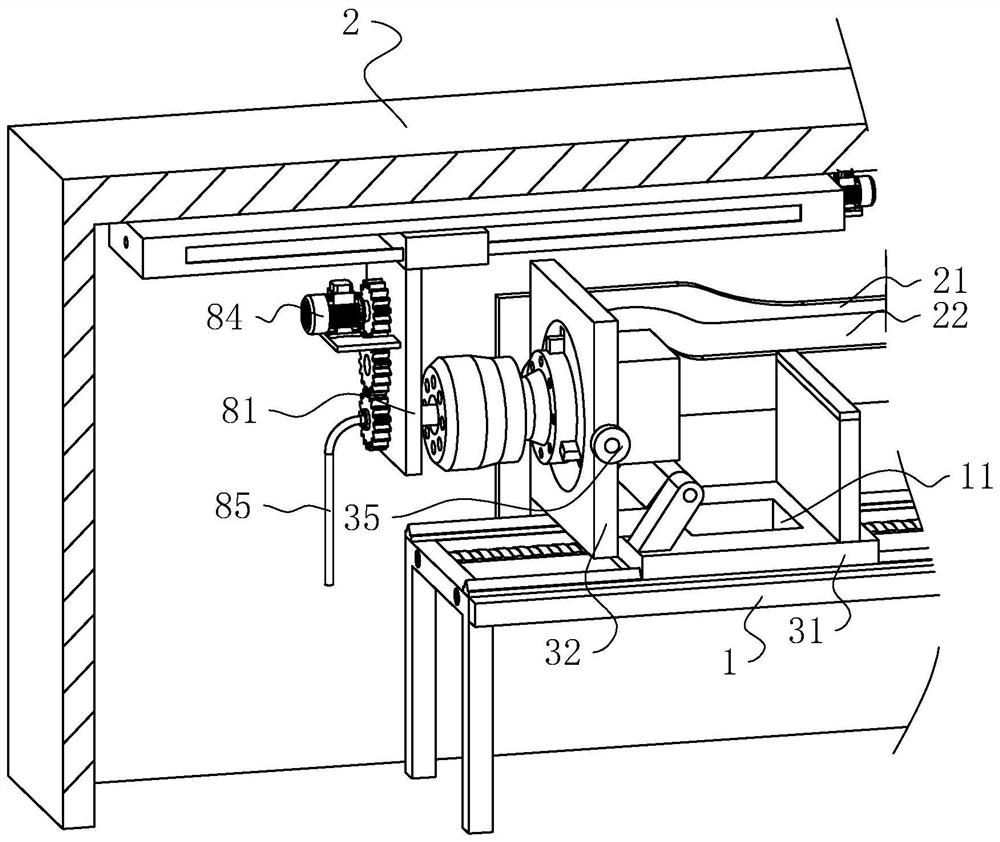

[0040] The following is attached Figure 1-6 The application is described in further detail.

[0041] The embodiment of the present application discloses a valve body processing technology, including the following steps:

[0042] Step1. Raw material preparation: confirm the raw material of the valve body, and transport it to the process to be processed;

[0043] Step2, milling shape: milling the shape of the valve body, using the cutter head to mill the large surface, and using the end mill to mill the steps;

[0044] Step3, Drill the installation hole: Use drilling equipment to process the installation hole;

[0045] Step4, Grinding: Use grinding equipment to grind the surface that needs to be polished;

[0046] Step5. Cleaning: use the cleaning line to clean the inner surface of the valve;

[0047] Step6. Drying: Dry the residual clean water on the surface of the valve body.

[0048] The embodiment of the present application also discloses a valve body processing equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com