Automatic steel cylinder welding device

An automatic welding and steel cylinder technology, which is used in grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve problems such as low welding efficiency, ensure welding quality, improve welding efficiency, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

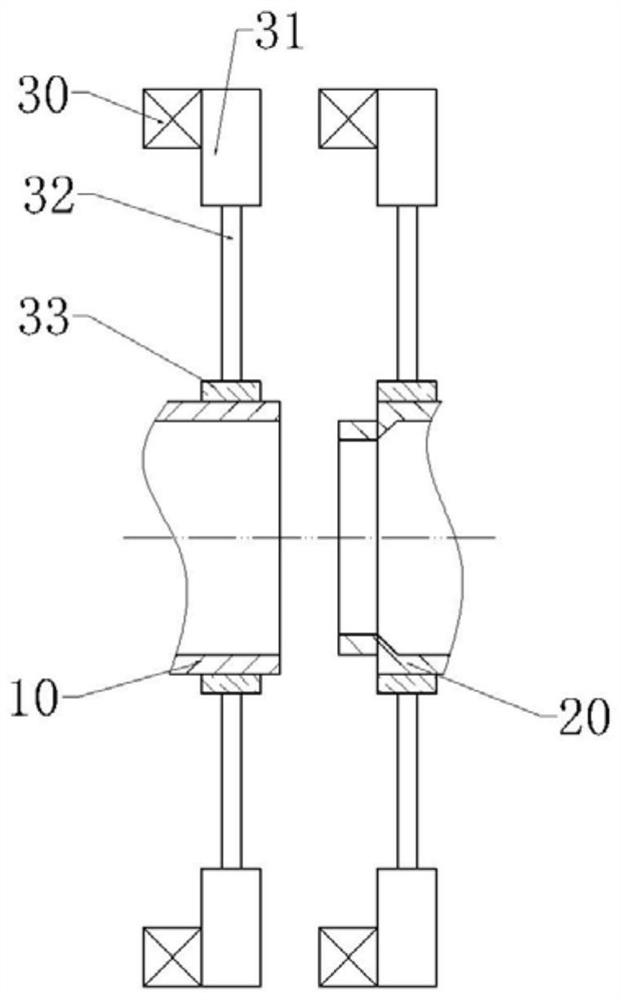

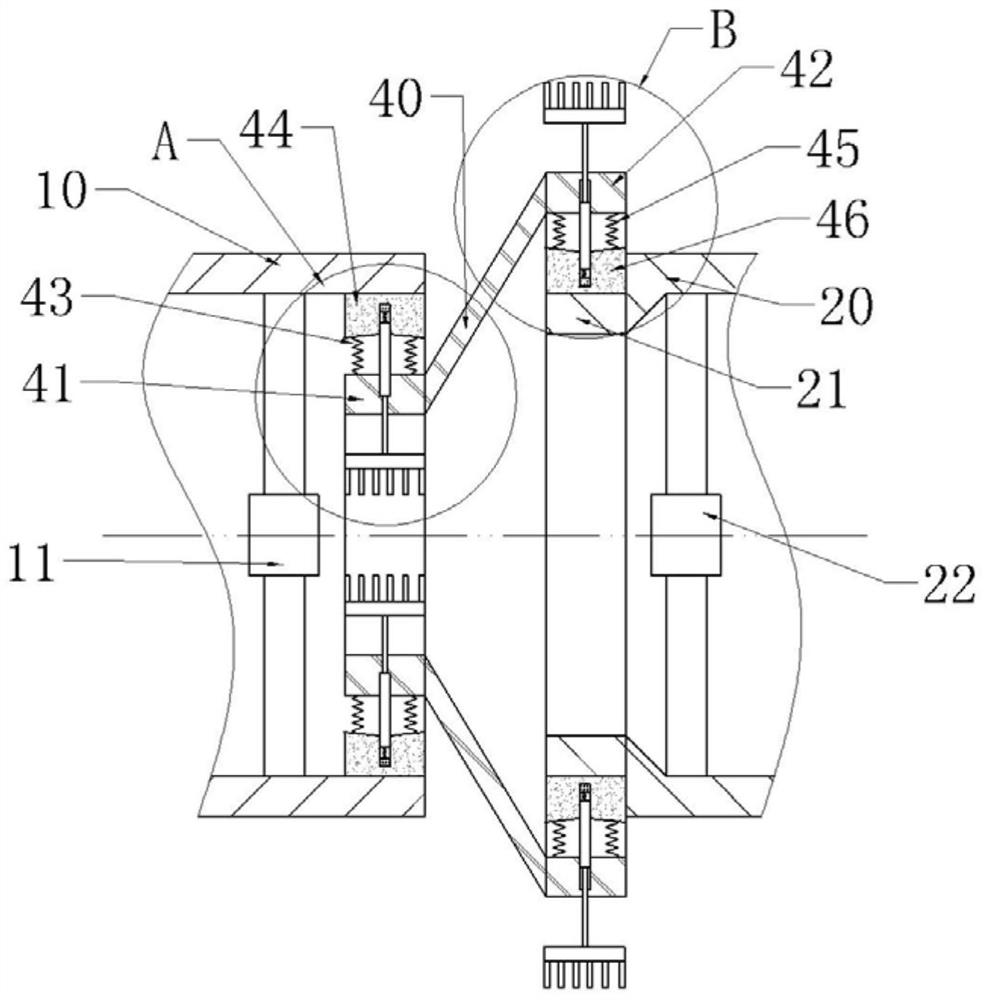

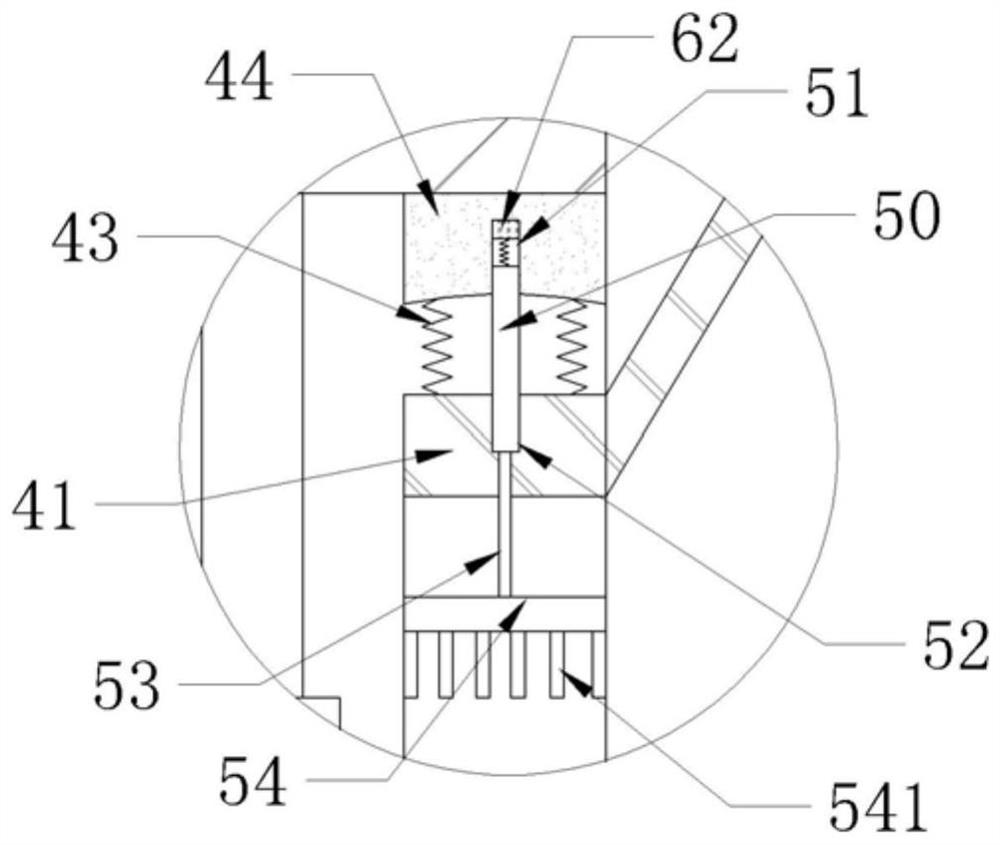

[0030] The reference signs in the drawings of the specification include: the first steel cylinder 10, the first fan blade 11, the second steel cylinder 20, the receiving ring 21, the second fan blade 22, the motor 30, the hydraulic cylinder 31, the telescopic shaft of the hydraulic cylinder 32. Arc plate 33, connecting cylinder 40, first fixed ring 41, second fixed ring 42, first spring 43, first grinding block 44, second spring 45, second grinding block 46, first sliding rod 50 , the first groove 51, the second groove 52, the first connecting rod 53, the first cooling plate 54, the first cooling fin 541, the third groove 55, the fourth groove 56, the second connecting rod 57, the first The second heat sink 58 , the second heat sink 581 , the second sliding rod 59 , the coil 60 , the magnet 61 , the first electromagnet 62 , and the second electromagnet 63 .

[0031] The embodiment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com