Plastic product perforating device capable of avoiding heating deformation

A punching device and plastic product technology, applied in the field of plastic product processing, can solve the problems of plastic damage, error, economic loss, etc., achieve the effect of smooth interior, excellent size, and avoid high temperature deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

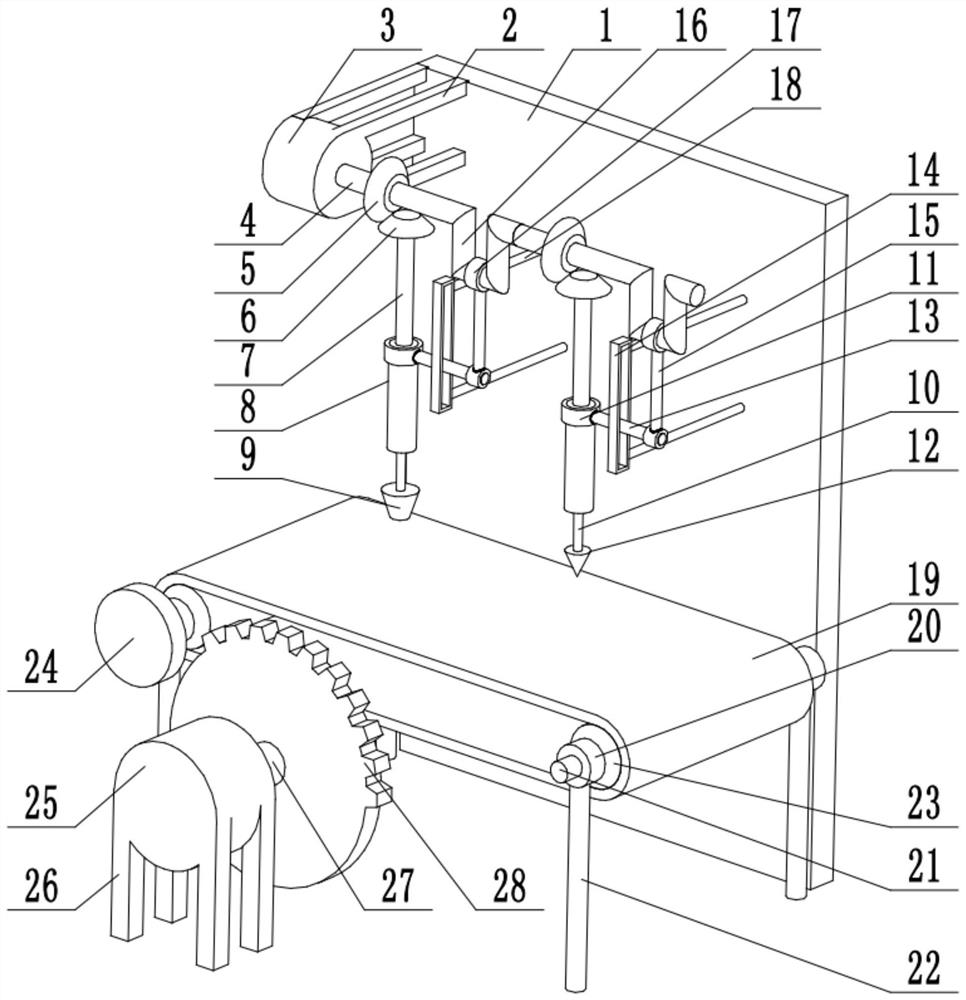

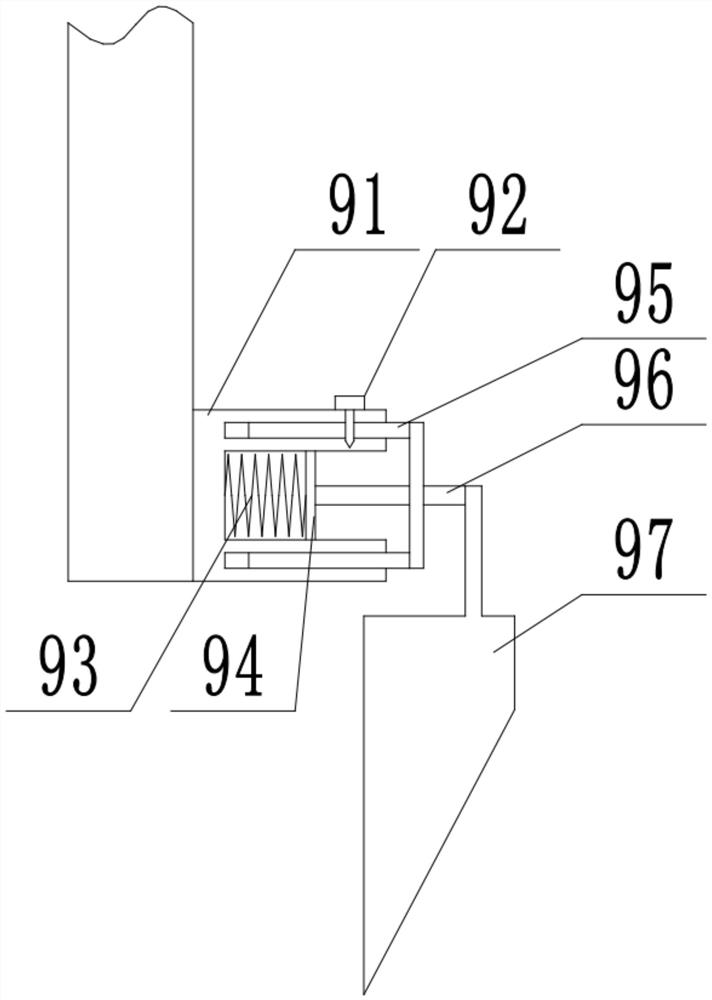

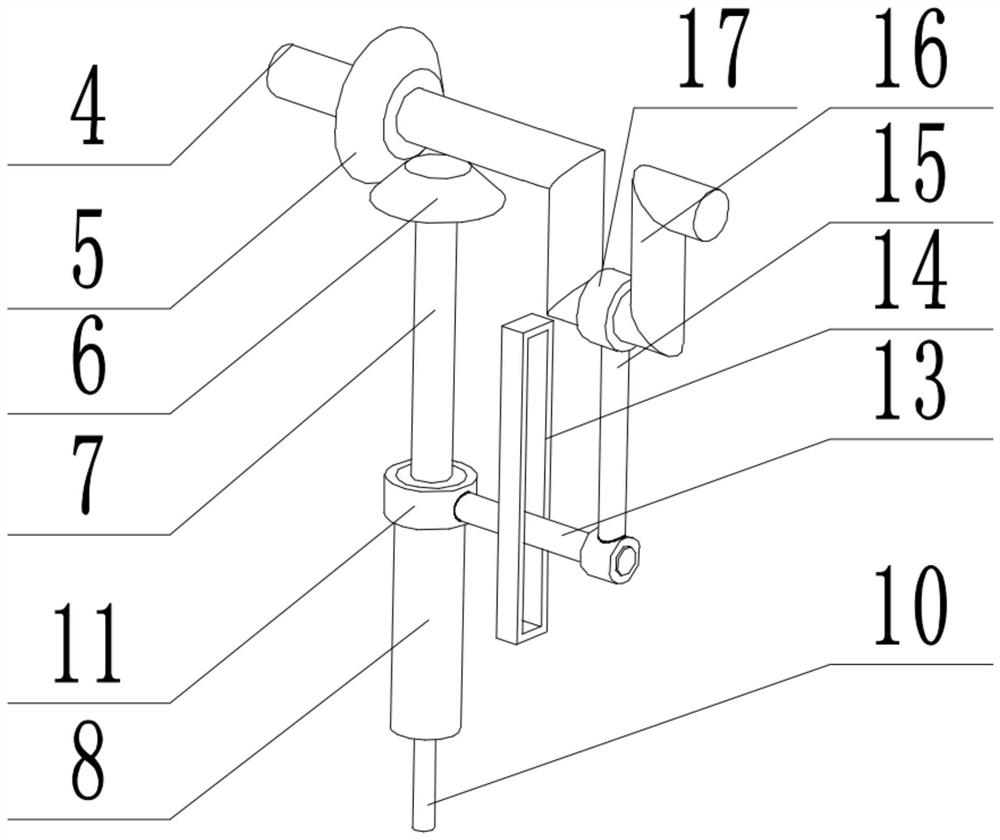

[0026] refer to Figure 1~3 , in an embodiment of the present invention, a plastic product punching device that avoids heating and deformation includes a first motor 3, and two sets of reciprocating devices are installed on one side of the first motor 3, and the reciprocating devices include a first output shaft 4 One side of the first output shaft 4 is equipped with a driving bevel gear 5, the lower part of the driving bevel gear 5 is meshed with a passive bevel gear 6, the lower end of the passive bevel gear 6 is fixed with a first rotating shaft 7, and the lower part of the first rotating shaft 7 is connected by a connecting key There is a second hollow rotating shaft 8, a first rod body 10 is installed at the lower end of the second hollow rotating shaft 8, a crank 16 is installed on one side of the output shaft, a rotating sleeve 17 is installed in the middle of the crank 16, and a second rotating sleeve is installed at the lower end of the rotating sleeve 17. Three rod b...

Embodiment 2

[0029] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a waste basket is provided on the left side of the intermittent conveying mechanism to conveniently collect plastic debris scattered on the conveyor belt.

[0030] The working principle of the present invention is: put the plastic product to be punched directly below the drill bit 12, adjust the positional relationship between the radius adjusting frame 95 and the cutting frame 91, so that the position of the cutting blade 97 is not in the same position as the first rod body 10 when it is not squeezed. The center point is the radius that needs to be punched, start the first motor 3, the first motor 3 drives the output shaft 4 to rotate, the output shaft 4 drives the active bevel gear 5 to rotate, the active bevel gear 5 drives the passive bevel gear 6 to rotate, and the passive bevel gear 6 drives the first rotating shaft 7 to rotate, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com