Environment-friendly waste rubber recycling and softening device for rubber production

A waste rubber and softening device technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of affecting the recycling effect, excessive heat loss, large volume, etc., and achieve the effect of uniform heating and softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

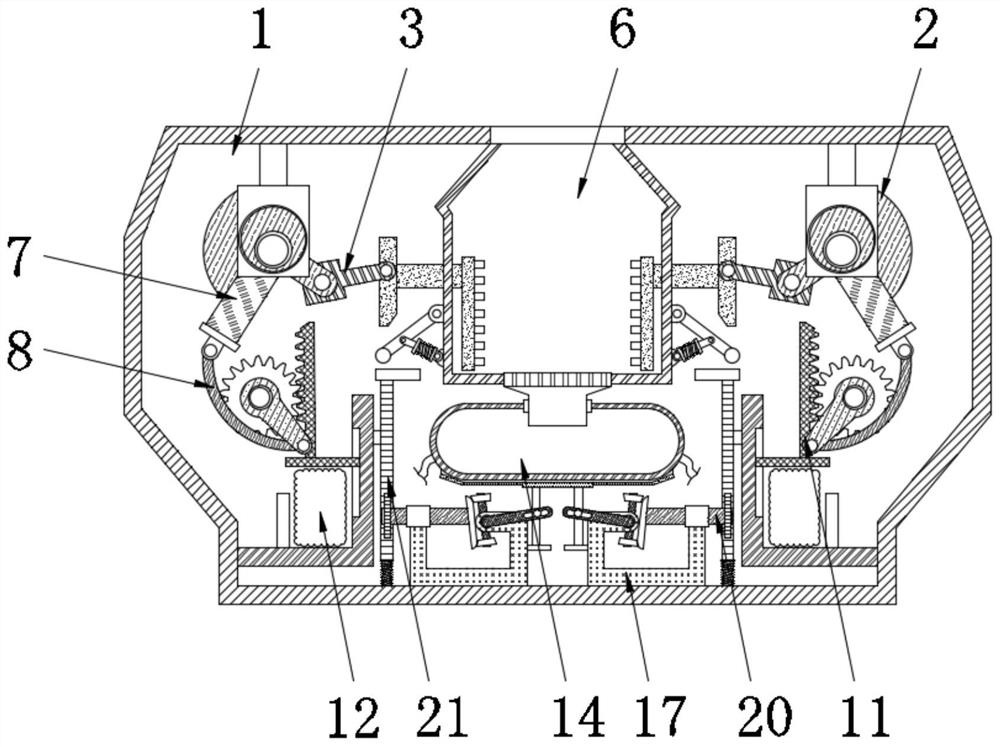

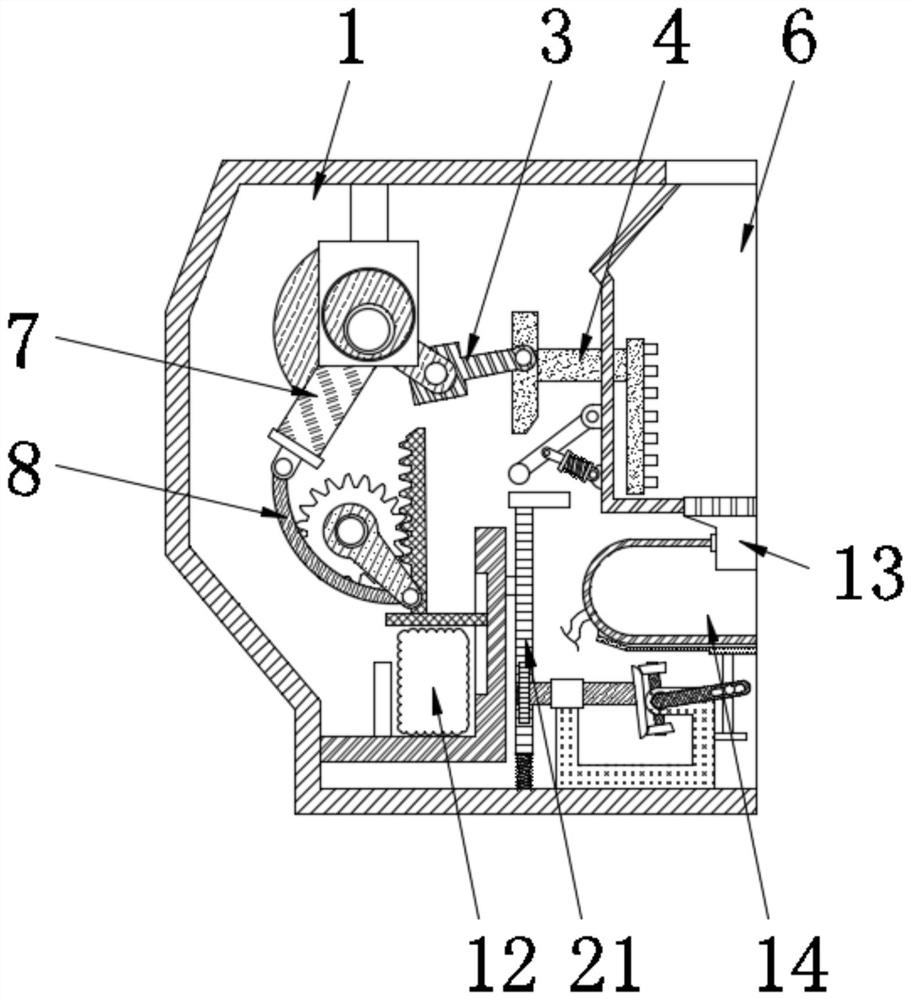

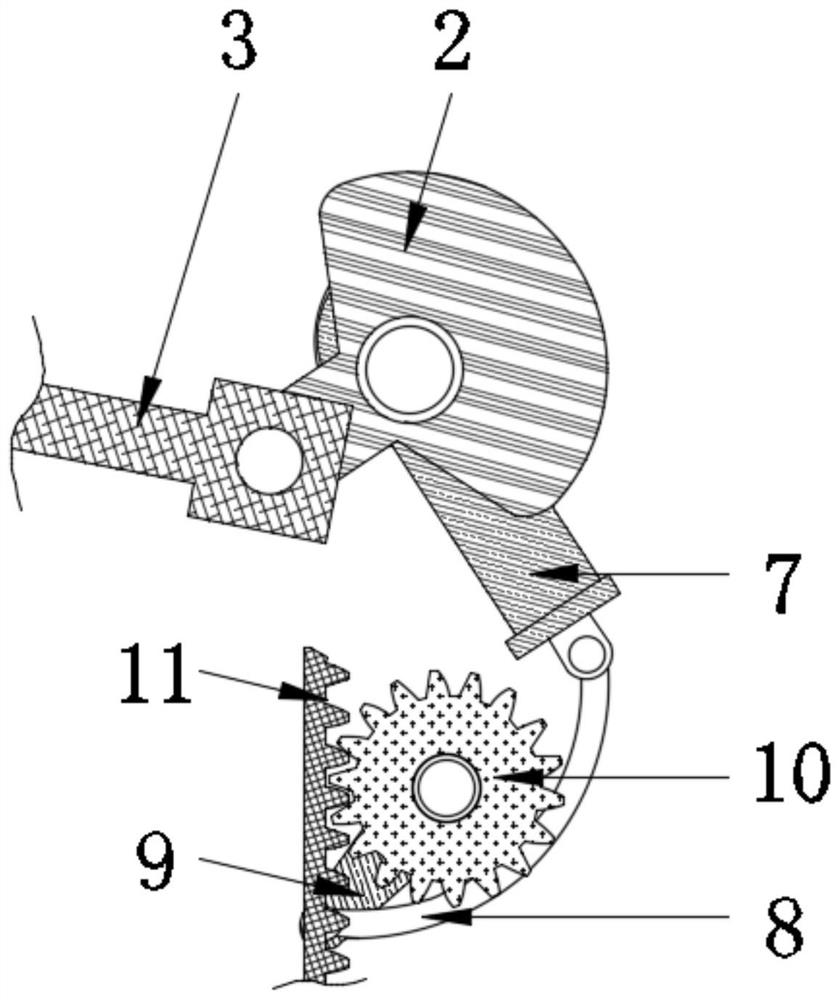

[0022] The invention provides an environment-friendly waste rubber recycling and softening device for rubber production, as attached figure 1 To attach Figure 5 As shown: including the recovery bin 1, the interior of the recovery bin 1 is installed with a fan-shaped plate 2, the fan-shaped plate 2 is fixedly installed on the output end of the motor, and the movable rod 3 is installed between adjacent fan-shaped plates 2, and the inner part of the movable rod 3 A push plate 4 is installed on the end, and the inner surface of the adjacent push plate 4 is fixedly equipped with a bump 5, and the push plate 4 runs through the inside of the collection tank 6, and the inner surface of the push plate 4 is equidistantly distributed with bumps 5, When the fan-shaped plate 2 rotates inside the disc, the internal movable rod 3 is driven to rotate, and the movable rod 3 drives the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com