Composite material tube forming tool system

A technology for composite material pipes and forming tooling, which is applied to tubular objects, household appliances, and other household appliances. It can solve the problems of difficult manufacturing of composite material pipes, complex working conditions, and complex layering, and achieve smooth surface quality and guaranteed The effect of high molding quality and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

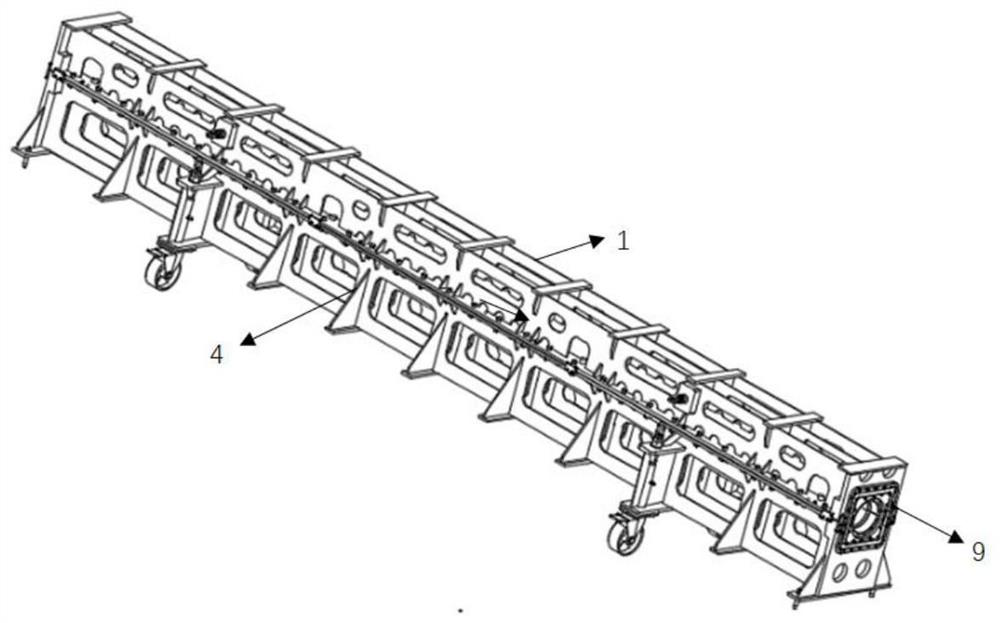

[0041] Such as Figure 3-14 As shown, a composite material pipe forming tooling system includes an upper mold body 1, a lower mold body 4, a cover plate 9 and an L-shaped auxiliary paving tooling 12; the end faces of the upper mold body 1 and the lower mold body 4 are provided There is a first sealing groove 2 for placing the first sealing strip 15, and the second sealing groove 5 for placing the second sealing strip 16 is arranged on the flange surface of the lower mold body 4, and the flange surface of the lower mold body 4 There are some first exhaust grooves 18 communicated with the cavity of the lower mold body 4, the second exhaust grooves 19 are communicated with the first exhaust grooves 18, and the top of the upper mold body 1 is provided with the second exhaust grooves 19. A number of connected vacuum quick connectors 3; the vertical surface of the auxiliary paving tool 12 is provided with a number of lost layer marking lines 13, when laying prepreg sheets in the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com