Oxidation ditch sewage treatment process

A sewage treatment and oxidation ditch technology, applied in water/sludge/sewage treatment, textile industry wastewater treatment, aerobic and anaerobic process treatment, etc. Insufficient thrust etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

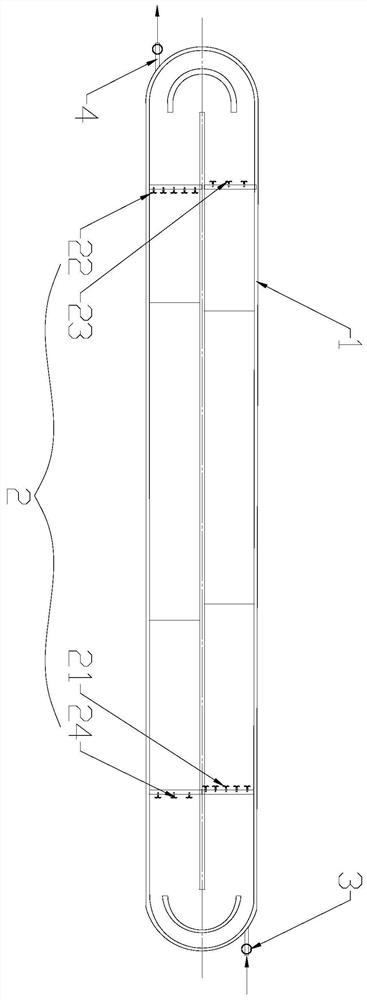

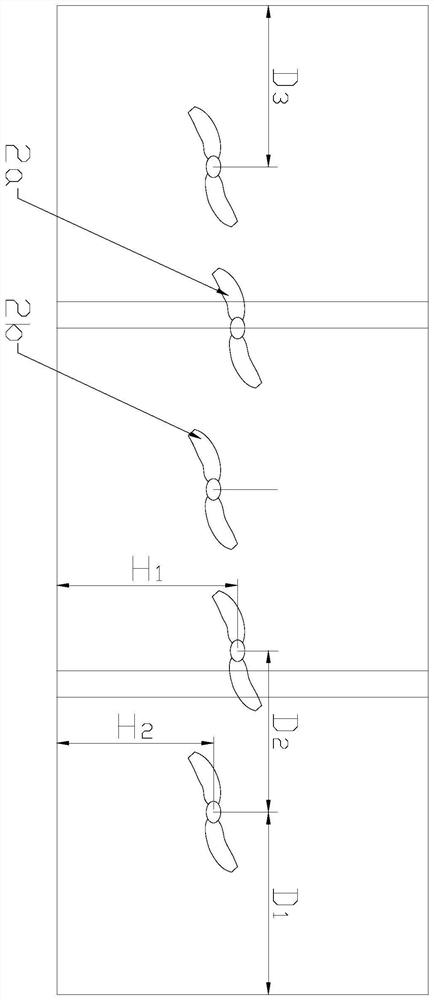

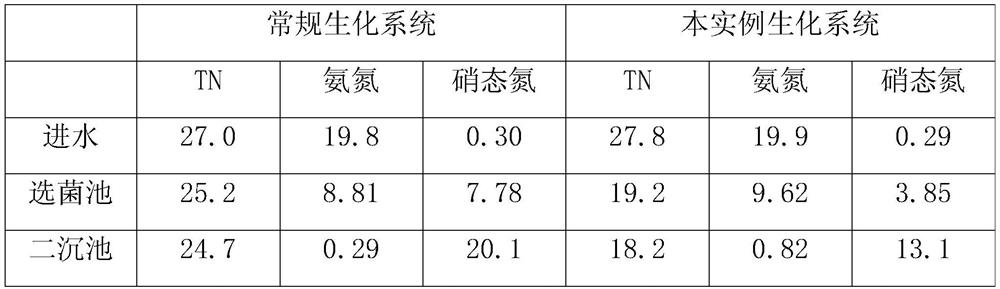

[0014] A kind of oxidation ditch sewage treatment process of the present embodiment, combines figure 1 , including reaction tank 1, water inlet pipe 3, water outlet area 4, vent area 5 and the aeration area and non-aeration area in reaction 1, the DO in the aeration area is 0.3-0.5mg / L, and the flow rate of the reaction tank is 0.5- 0.8m / s, the water inlet pipe 3 is connected to the bottom of the reaction pool 1, the vent area 5 and the water outlet area 4 are both set in the middle of the reaction pool 1, and distributed at both ends of the reaction pool 1, the water outlet area 4 and the water inlet pipe 3 can be set at the same end , the middle part of the reaction tank 1 is provided with a clapboard, and the reaction tank 1 is distributed with flowmakers 2, i.e. the first flowmaker 21, the second flowmaker 22, the third flowmaker 23 and the fourth flowmaker 24, the second flowmaker A flow mover 21 and a third flow mover 23 are located on the same side of the partition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com