Quick ageing device for semi-hydrated calcined gypsum powder

An ageing device and gypsum powder technology are applied in the field of gypsum materials and can solve the problems of low ageing and homogenization efficiency, unsatisfactory ageing and homogenization effect, low efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

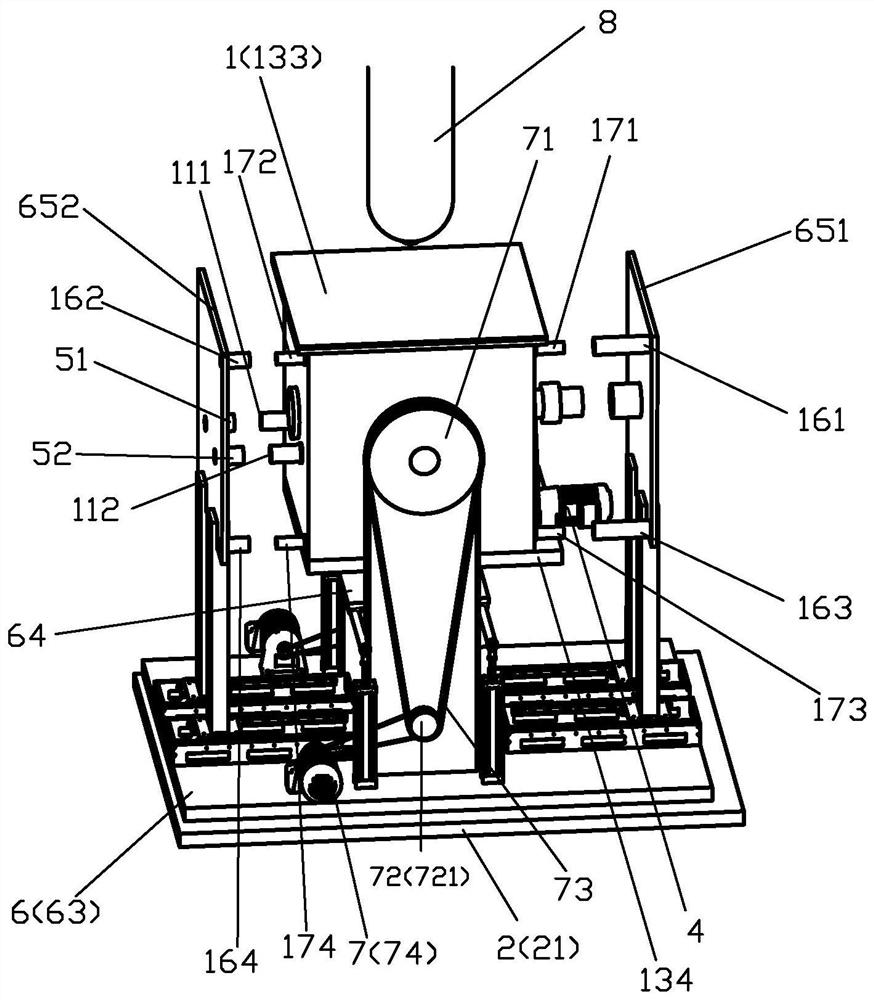

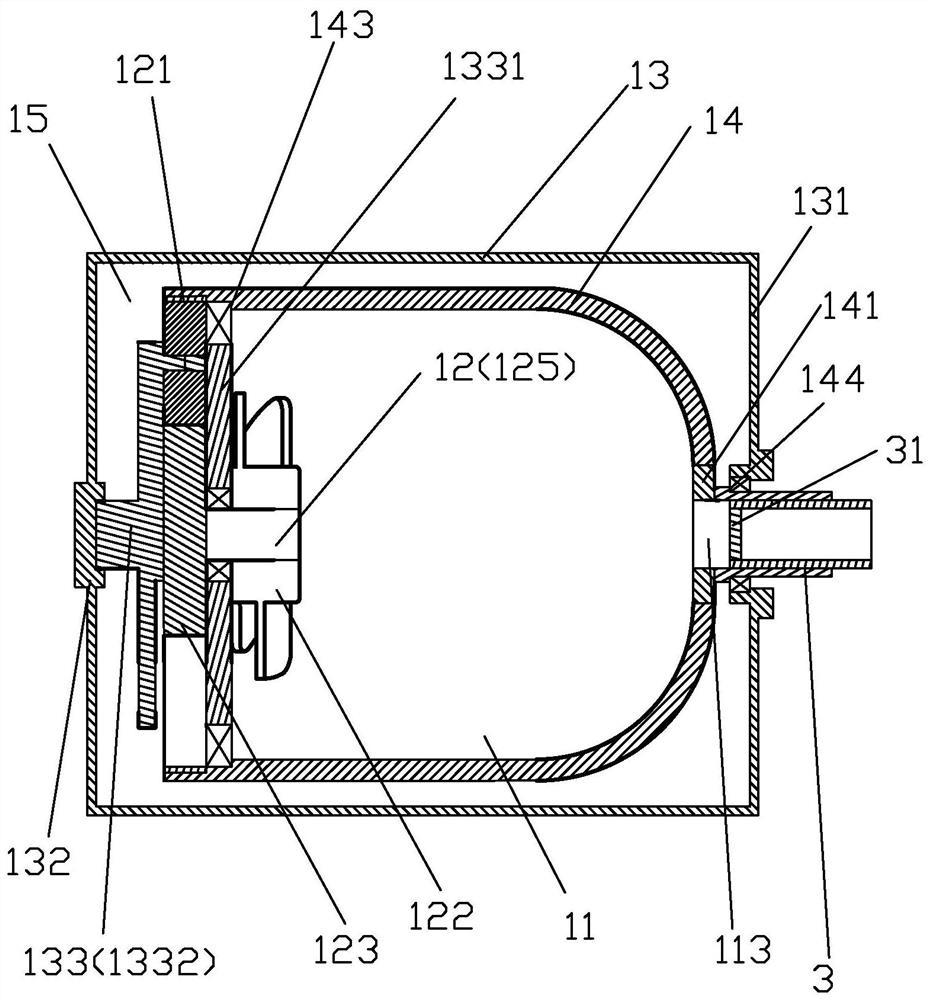

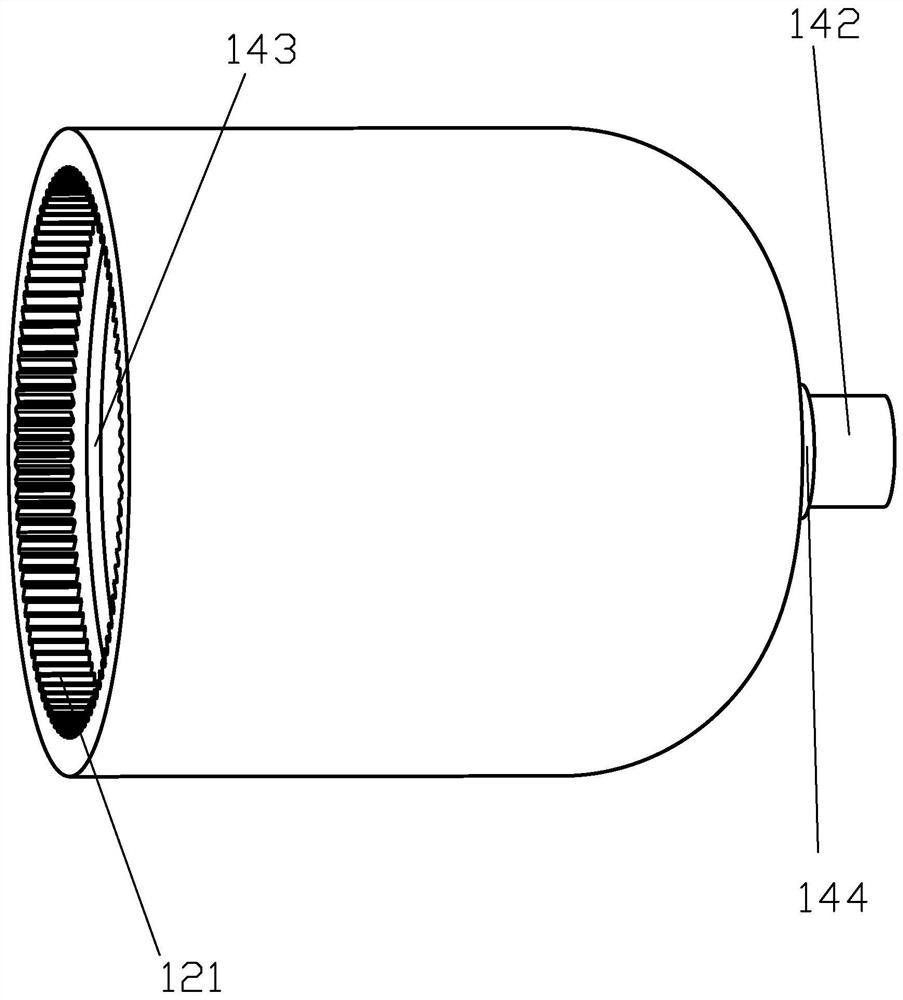

[0079] Such as Figure 1-5 Shown, a kind of semi-water calcined gypsum powder rapid aging device, comprises housing 1 and is arranged on the weighing device 2 below housing 1; Housing 1 has sealing chamber 11 and stirring device 12 for stirring gypsum powder; Housing 1 It has a dry air inlet 111 for dry air to enter the sealed chamber 11, a water vapor inlet 112 for water vapor to enter the sealed chamber 11, and a material hole 113 for materials to enter and exit; it also includes a temperature control device for regulating the temperature of the sealed chamber 11, And the wet air discharge pipe 3 that is detachably connected with the material hole 113. In the actual implementation process, open the feed port and put the desulfurized gypsum powder into the sealed room, open the dry air inlet, connect the humid air discharge pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com