Preparation method for preparing alpha-type high-strength gypsum by self-steam-curing method

A technology for high-strength gypsum and phosphogypsum, which is applied in the field of preparing α-type high-strength gypsum by auto-curing method, can solve the problems of inability to meet the requirements of environmental protection production industrialization, complicated process and high cost, and achieves superior cost performance, simple operation and high water consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

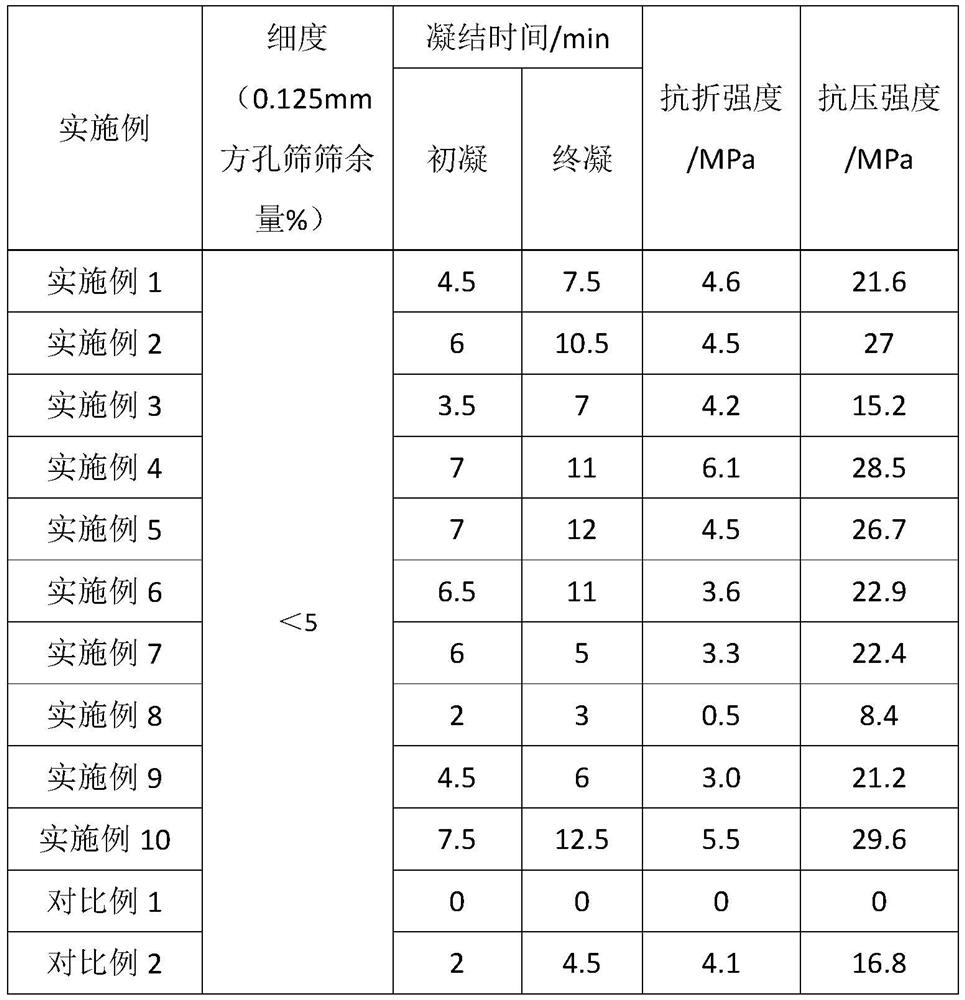

Examples

Embodiment 1

[0030] A method for preparing high-strength gypsum by utilizing phosphogypsum, comprising the following steps: 1) Pretreatment of phosphogypsum: take an appropriate amount of phosphogypsum, add tap water and wash 13 times for pretreatment according to the water-to-paste ratio of 1:2.5, so that the pH value is neutral 2) preparation of phosphogypsum slurry: take by weighing polycarboxylate (sodium citrate) at 0.08% by phosphogypsum mass ratio, stir the crystal modifier and water in a beaker to make the crystal modifier completely dissolved in water, then Pour the mixed solution into the pretreated phosphogypsum and stir to prepare a thick paste. The solid-to-water ratio of phosphogypsum and the mixed solution is 3:1; 3) steam curing treatment: put the prepared slurry into an aluminum box and seal it . Steam curing in an oven at normal pressure and temperature of 140°C, constant temperature for 10h; 4) Drying and grinding of autoclaved materials: drying the steamed materials at ...

Embodiment 2

[0032] A method for preparing high-strength gypsum by utilizing phosphogypsum, comprising the following steps: 1) Pretreatment of phosphogypsum: take an appropriate amount of phosphogypsum, add tap water and wash 13 times for pretreatment according to the water-to-paste ratio of 1:2.5, so that the pH value is neutral 2) preparation of phosphogypsum slurry: take by weighing polycarboxylate (sodium citrate) at 0.08% by phosphogypsum mass ratio, stir the crystal modifier and water in a beaker to make the crystal modifier completely dissolved in water, then Pour the mixed solution into the pretreated phosphogypsum and stir to prepare a thick paste. The solid-to-water ratio of phosphogypsum and the mixed solution is 3:1; 3) steam curing treatment: put the prepared slurry into an aluminum box and seal it . Steam curing in an oven at normal pressure and temperature of 140°C, constant temperature for 6 hours; 4) Drying and grinding of autoclaved materials: drying the steamed materials...

Embodiment 3

[0034] A method for preparing high-strength gypsum by utilizing phosphogypsum, comprising the following steps: 1) Pretreatment of phosphogypsum: take an appropriate amount of phosphogypsum, add tap water and wash 13 times for pretreatment according to the water-to-paste ratio of 1:2.5, so that the pH value is neutral 2) preparation of phosphogypsum slurry: take by weighing polycarboxylate (sodium citrate) at 0.08% by phosphogypsum mass ratio, stir the crystal modifier and water in a beaker to make the crystal modifier completely dissolved in water, then Pour the mixed solution into the pretreated phosphogypsum and stir to prepare a thick paste. The solid-to-water ratio of phosphogypsum and the mixed solution is 3:1; 3) steam curing treatment: put the prepared slurry into an aluminum box and seal it . Steam curing in an oven at normal pressure and temperature of 140°C, constant temperature for 4 hours; 4) Drying and grinding of autoclaved materials: drying the steamed materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com