Hydrogel-elastomer complex as well as preparation method and application thereof

A hydrogel and elastomer technology, applied in the field of hydrogel-elastomer composite and its preparation, can solve the shape distortion of the composite, the loss of water in the hydrogel, the inability to prepare the hydrogel-elastomer composite, etc. problem, to achieve the effect of improving the bonding strength and avoiding shape distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for preparing a hydrogel-elastomer composite, comprising the following steps:

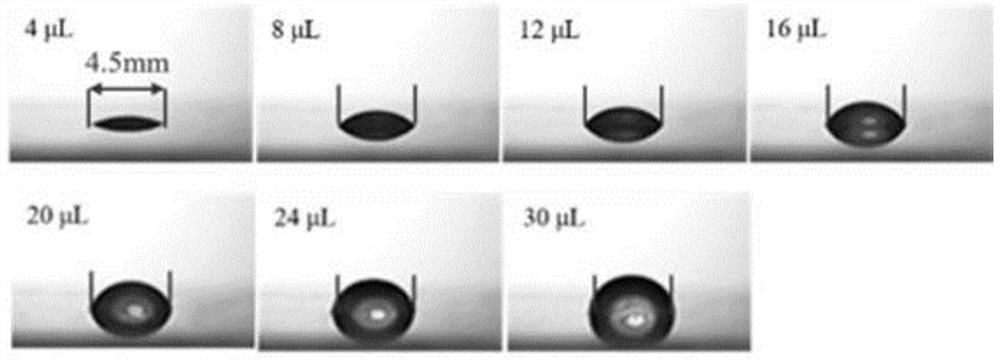

[0062] (1) Carry out partial plasma etching treatment to the surface of hydrophobic elastomer substrate (PDMS-184 of Dow Corning Company), the plasma that adopts is oxygen plasma, and intensity is 30Pa, and etching time is 10s, forms circular (diameter 4.5mm) hydrophilic area;

[0063] (2) Add the hydrogel precursor solution dropwise on the hydrophilic region obtained in step (1) (the volumes added are 4 μL, 8 μL, 12 μL, 16 μL, 20 μL, 24 μL, 30 μL), and the hydrogel precursor solution spontaneously Covering the hydrophilic region to form droplets with a certain curved surface profile;

[0064] Among them, the preparation method of the hydrogel precursor solution is as follows: 1mL acrylamide solution (8mol / L), 1mL photoinitiator LAP (concentration: 0.05wt%), 32μL cross-linking agent N,N'-methylenebis Acrylamide (MBAA, 0.1mol / L) and 24 μL of silane coupling...

Embodiment 2

[0068] This embodiment provides a method for preparing a hydrogel-elastomer composite, comprising the following steps:

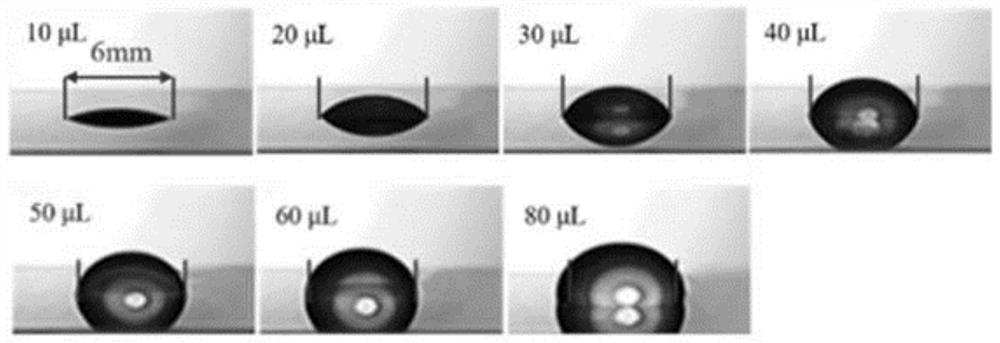

[0069] (1) Perform partial plasma etching treatment on the surface of the hydrophobic elastomer substrate (PDMS-184), the plasma used is oxygen plasma, the intensity is 30Pa, the etching time is 10s, and a circular (diameter 6mm) is formed. Hydrophilic area;

[0070] (2) Add the hydrogel precursor solution dropwise on the hydrophilic region obtained in step (1) (the volumes added are 10 μL, 20 μL, 30 μL, 40 μL, 50 μL, 60 μL, 80 μL), and the hydrogel precursor solution spontaneously Covering the hydrophilic region to form droplets with a certain curved surface profile;

[0071] Among them, the preparation method of the hydrogel precursor solution is as follows: 1mL acrylamide solution (8mol / L), 1mL photoinitiator LAP (concentration is 0.05wt%), 32μL crosslinking agent MBAA (0.1mol / L) and 24μL The silane coupling agent γ-methacryloxypropyltrimethoxysilane is...

Embodiment 3

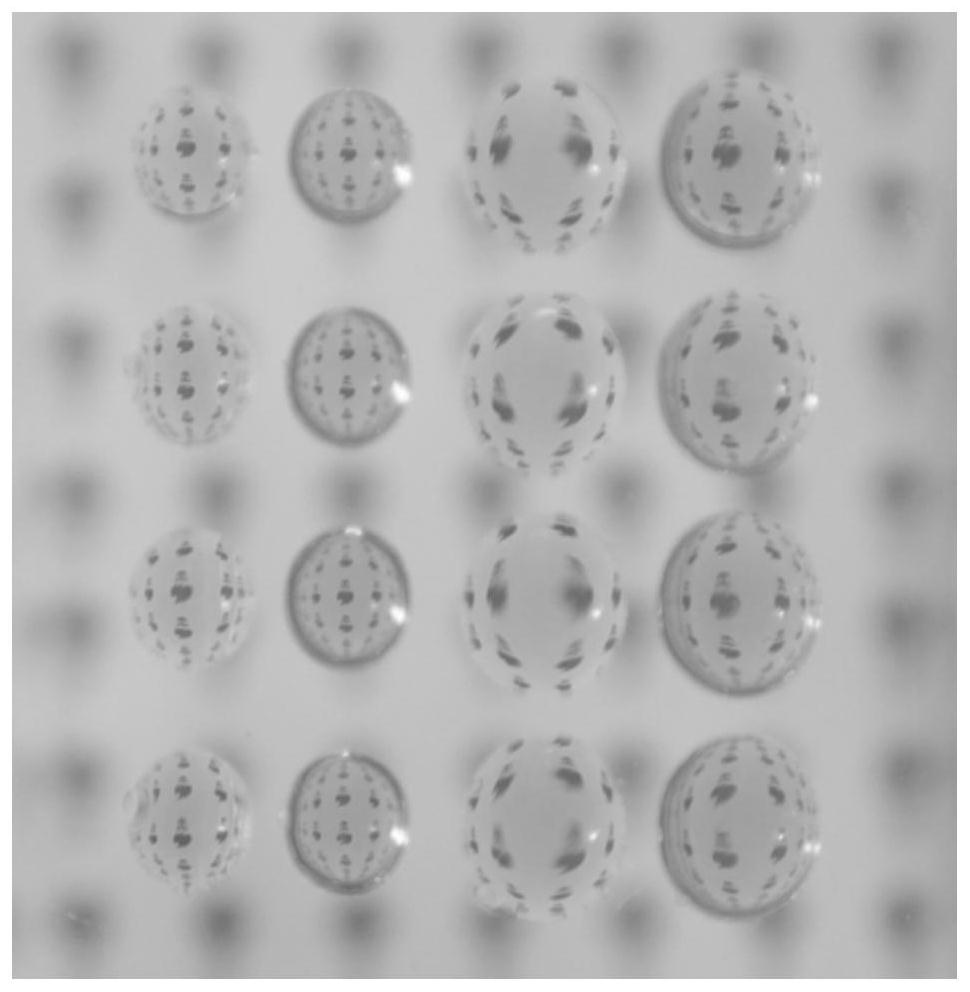

[0075] This embodiment provides a zoom microlens matrix (4 * 4), and its preparation method is as follows:

[0076] (1) Perform partial plasma etching treatment on the surface of the hydrophobic elastomer substrate (PDMS-184), the plasma used is oxygen plasma, the intensity is 30Pa, the etching time is 10s, and the formation is arranged in a 4×4 matrix The circular hydrophilic region;

[0077] Among them, the diameters of the same row of hydrophilic regions are the same, and the diameters of the first row to the fourth row of hydrophilic regions are 4.5mm, 4.5mm, 6mm, and 6mm respectively;

[0078] (2) Add the hydrogel precursor solution dropwise on the hydrophilic regions obtained in step (1) (the amount of the same row of hydrophilic regions is the same, and the volumes of the first row to the fourth row of hydrophilic regions are respectively 10 μL , 15 μL, 15 μL, 20 μL), the hydrogel precursor solution spontaneously covers the hydrophilic region, forming droplets with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com