High-performance PVC pipe for drainage and preparation method thereof

A PVC pipe, high-performance technology, used in applications, household appliances, tubular objects, etc., can solve the problems of durability, poor pressure bearing capacity, and fragility, so as to reduce operation difficulty and labor intensity, increase pressure bearing capacity, Reliable effect of the connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

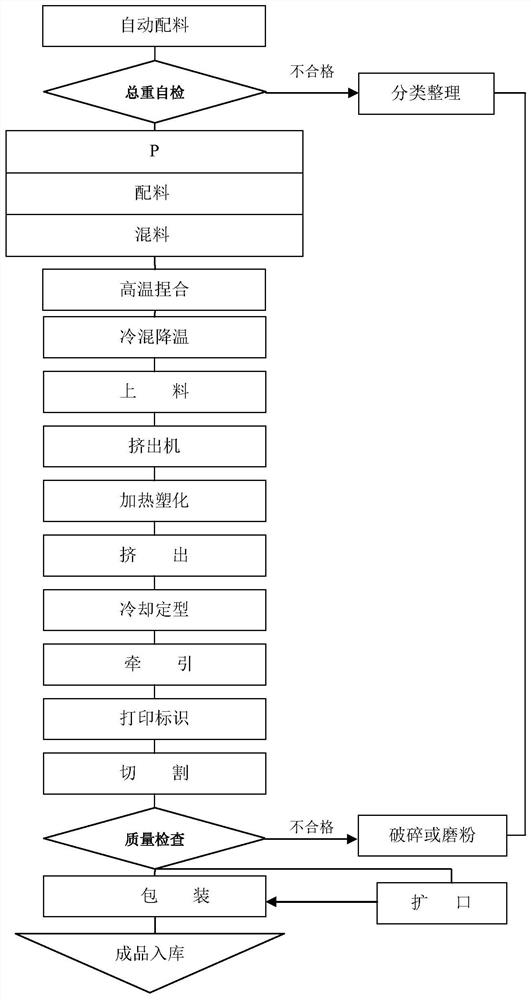

Method used

Image

Examples

Embodiment 1

[0063] A high-performance PVC pipe for drainage, characterized in that it includes the following raw materials in parts by weight:

[0064] 100 parts of PVC main material; 2 parts of titanium dioxide; 0.8 parts of organotin; 0.7 parts of KG-16 internal lubricant; 0.3 parts of PE wax; 0.1 part of oxidized polyethylene wax; 0.2 parts of calcium; 2 parts of MBS impact modifier; 8 parts of calcium carbonate; 2 parts of green mother.

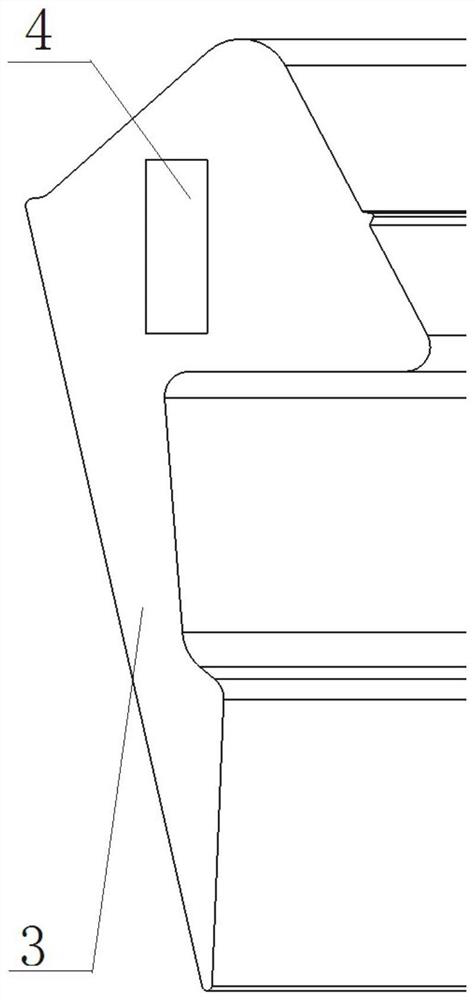

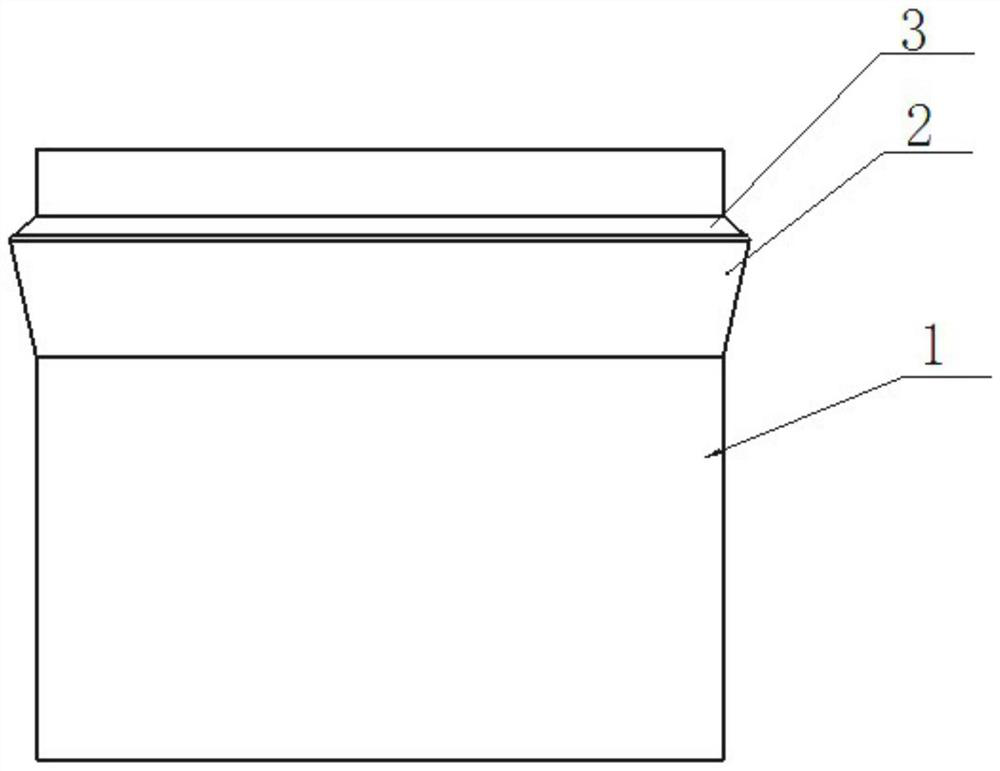

[0065] Moreover, the structure of the PVC pipe 1 includes a flaring 2, and an apron 3 is fixed at the flaring 2. When the pipe is flaring, the apron 3 and the pipe 1 are integrally formed; and inside the apron 3, a steel lining Ring 4.

[0066] The PVC main material is PVC-SG-5; titanium dioxide and organotin are T105 titanium dioxide and T106 organotin respectively.

Embodiment 2

[0068] A high-performance PVC pipe for drainage, characterized in that it includes the following raw materials in parts by weight:

[0069] 100 parts of PVC main material; 0.5 parts of titanium dioxide; 1.3 parts of organotin; 0.2 parts of KG-16 internal lubricant; 0.9 parts of PE wax; 0.02 parts of oxidized polyethylene wax; 0.4 parts of glyceryl monostearate GMS; 0.04 parts of calcium; 6.4 parts of MBS impact modifier; 1 part of calcium carbonate; 3.7 parts of green mother;

[0070] In addition, the PVC pipe structure includes flaring, and an apron is fixed at the flaring place. When the pipe is flaring, the apron and the pipe are integrally formed; and the apron is lined with a steel ring.

Embodiment 3

[0072] A high-performance PVC pipe for drainage, characterized in that it includes the following raw materials in parts by weight:

[0073] 100 parts of PVC main material; 4 parts of titanium dioxide; 0.4 parts of organotin; 1.4 parts of KG-16 internal lubricant; 0.1 part of PE wax; 0.17 parts of oxidized polyethylene wax; 0.45 parts of calcium; 0.5 parts of MBS impact modifier; 1 part of calcium carbonate; 0.6 parts of green mother;

[0074] In addition, the PVC pipe structure includes flaring, and an apron is fixed at the flaring place. When the pipe is flaring, the apron and the pipe are integrally formed; and the apron is lined with a steel ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com