Wood drying and preservative treatment device

A technology for anti-corrosion treatment and wood drying, which is applied in the processing of dry goods, the arrangement of dry gas, and the drying of solid materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

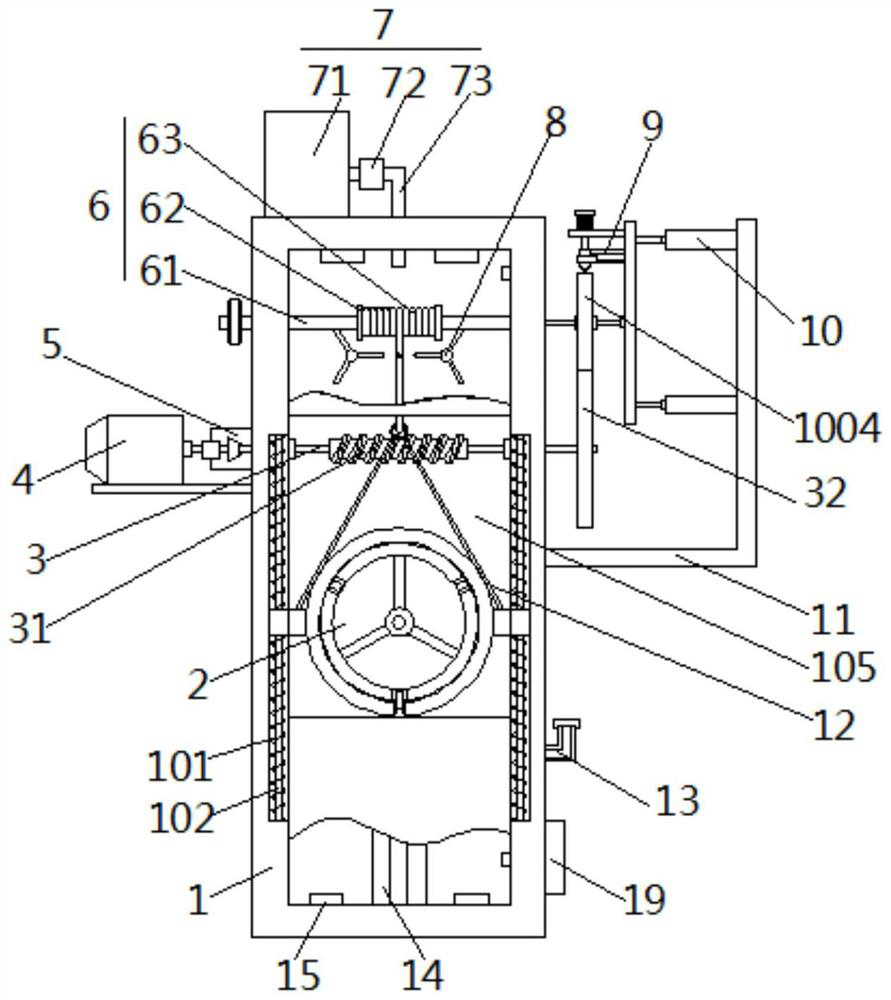

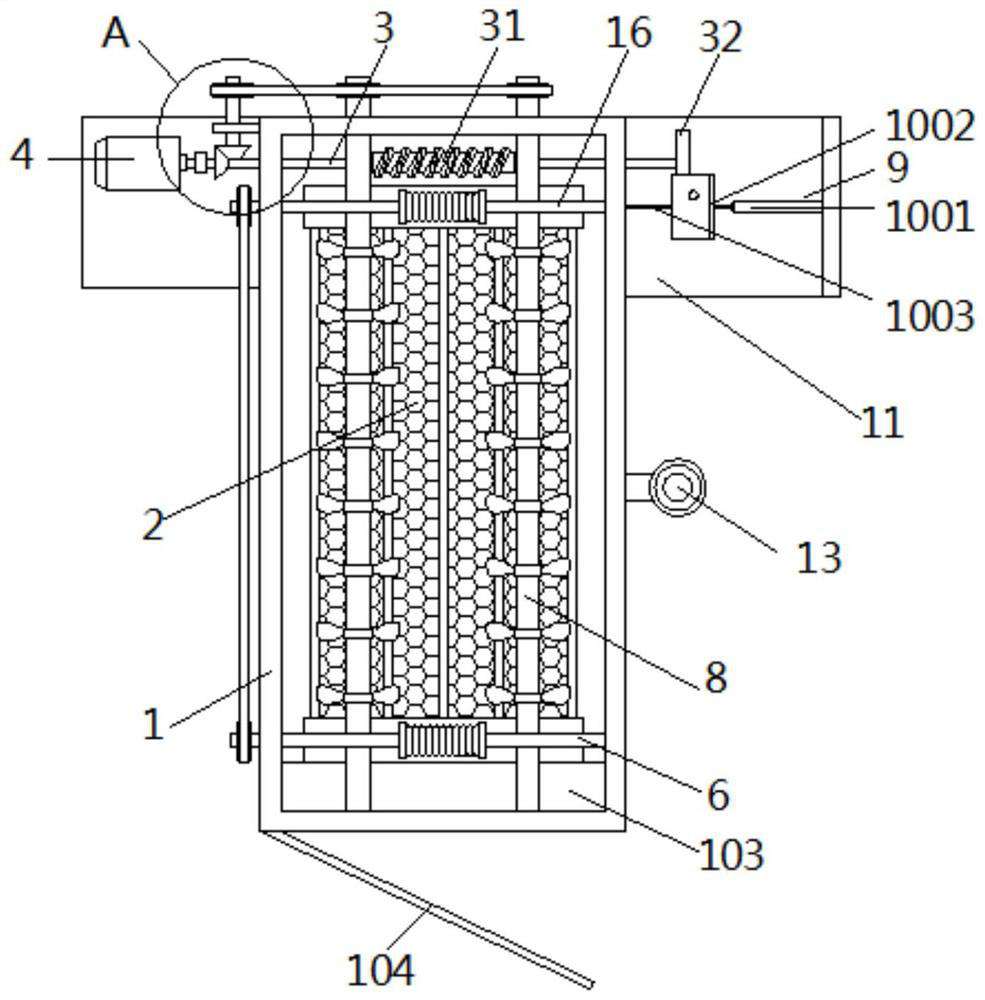

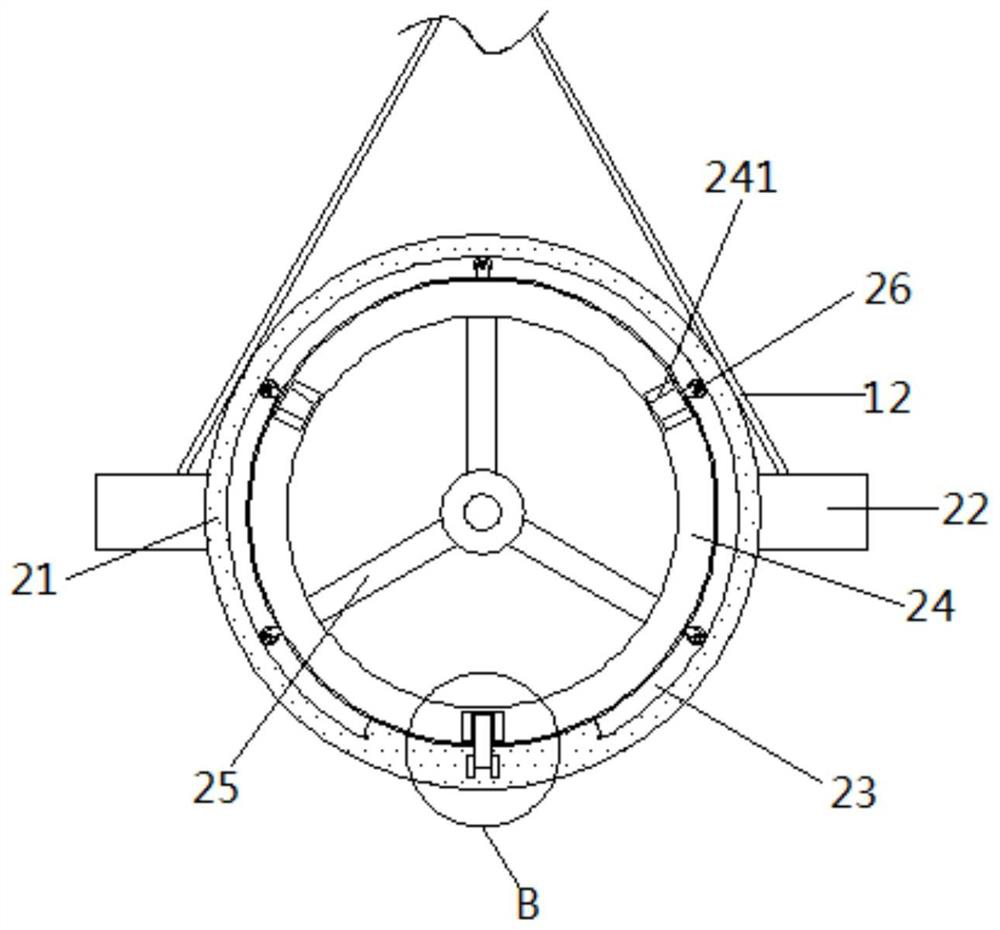

[0033] as attached figure 1 To attach Figure 10 Shown: a wood drying anticorrosion treatment device, including a box body 1, a loading device 2, a loading device 2 is installed between the left and right sides inside the box body 1, and steel bars are fixedly connected between the left and right sides of the front and rear ends of the loading device 2 Rope 12, the inside of the box body 1 is located at the front and rear sides of the top of the loading device 2, and the upper ends are respectively horizontally rotated and connected to the No. 1 retracting device 6 and the No. 2 retracting device 16. The No. 1 retracting device 6 and the No. The steel rope 12 at the front and rear ends of the device 2 is fixedly connected, and the inside of the box body 1 is located at the upper end of the rear side of the loading device 2. The left and right ends of the center between the front and rear sides of the retracting device 6 and the No. 2 retracting device 16 are longitudinally ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com