In-situ inspection method and device for leakage of condenser heat exchange tube

A technology for condensers and heat exchange tubes, applied in steam/steam condensers, by detecting the appearance of fluid at leak points, lighting and heating equipment, etc., it can solve the problem of incorrect diagnostic results of condenser leak detection and the number of sampling points less, long measurement lag time, etc., to avoid cross-contamination of water samples, strong representativeness, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

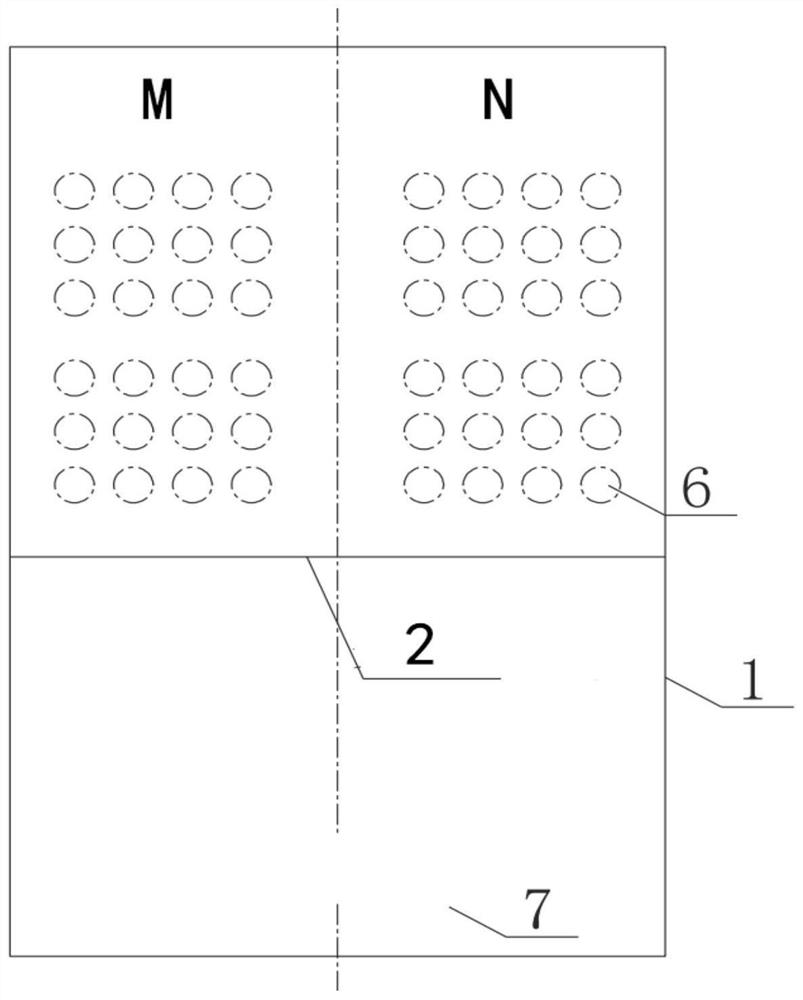

[0047] as attached figure 1 , the guide rail 2 inside the condenser 1 and the inspection vehicle 3 are located below the condenser tube 6 and above the hot well 7 at the bottom of the condenser. The exhaust steam from the steam turbine is condensed through the condenser tube 2 in the condenser 1. When the condensed water drops to the hot well 7 at the bottom of the condenser, condensed water from different positions continuously enters the inspection vehicle 3 for testing.

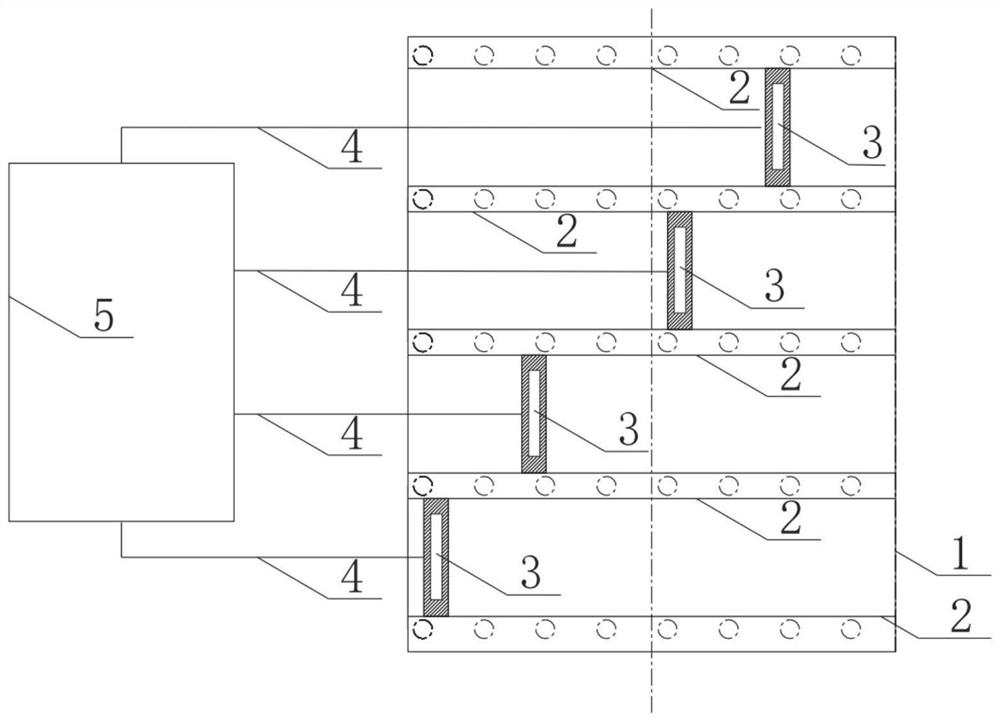

[0048] as attached figure 2 A guide rail 2 is laid above the hot well 7 at the bottom of the condenser, and the two ends of the inspection vehicle 3 are mounted on the guide rail 2. The power and control system 5 provides power and control to the inspection vehicle 3 through the control line 4. Each water chamber of the condenser 1 is arranged with several guide rails 2 and inspection vehicles 3 along the vertical length direction of the condenser tube 6, and the inspection vehicle 3 reciprocates on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com