Method and device for detecting water quality of oilfield water injection wellbore in situ

A technology for oil field water injection and in-situ detection, which is used in measurement devices, scattering characteristics measurement, particle size analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

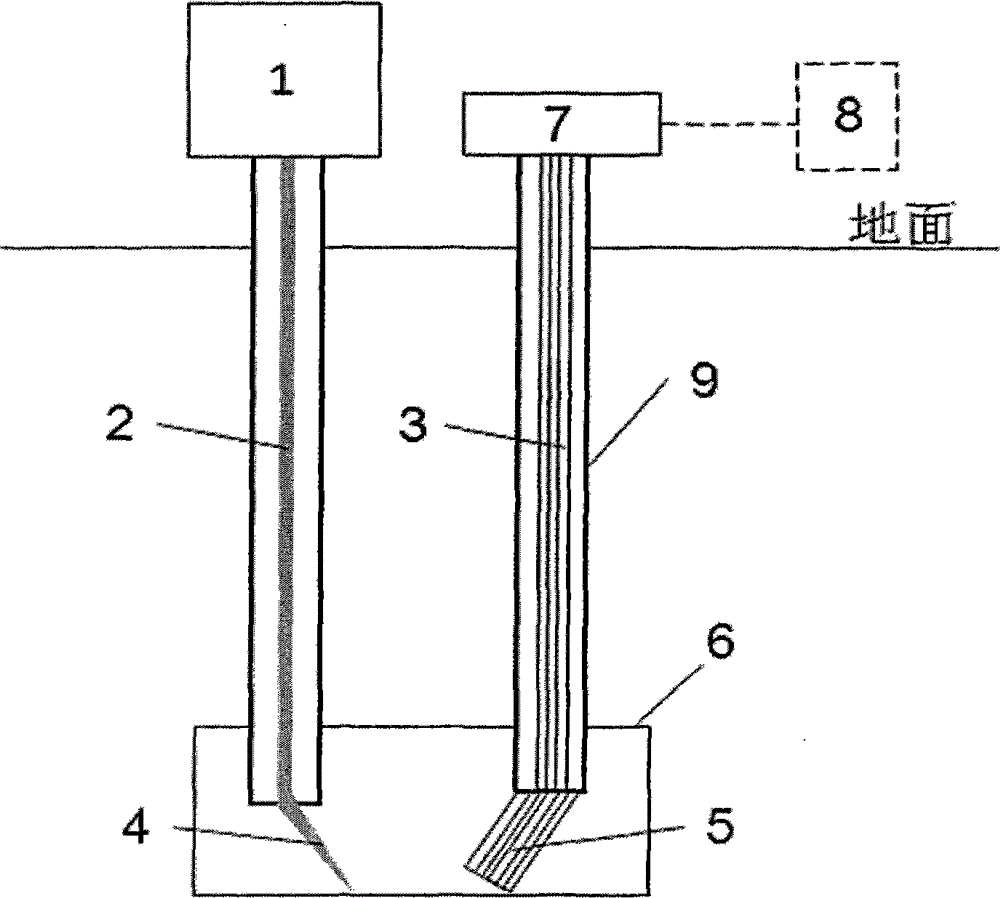

Method used

Image

Examples

example 1

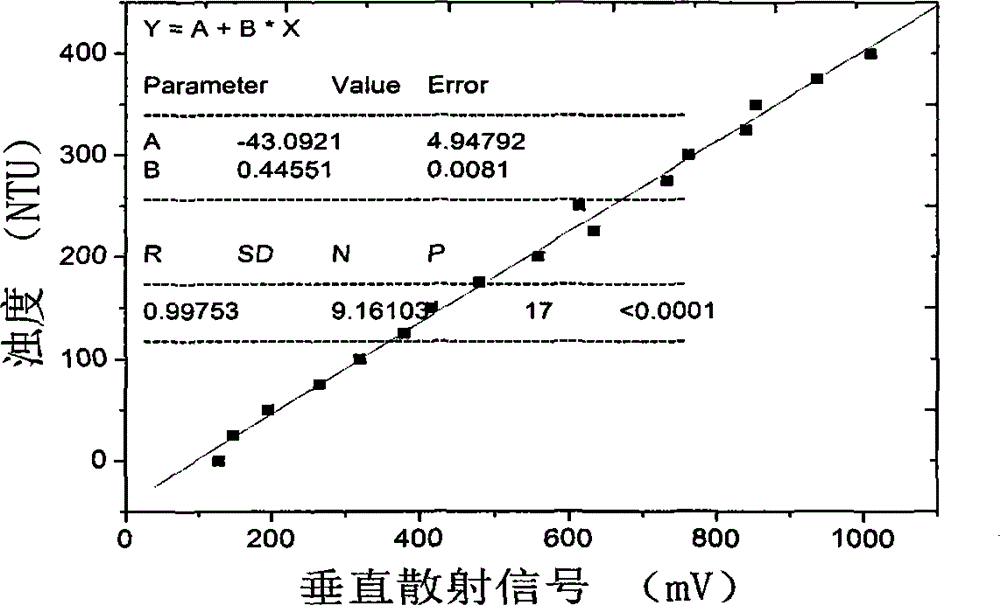

[0028] Example 1, the test of turbidity figure 2 shown

[0029] Formaldehyde standard solutions with different turbidities were prepared for experiments. The results show that the intensity of scattered signal increases monotonously with the increase of turbidity. In the low turbidity area, the correlation coefficient of the first fit is above 0.99 (

example 2

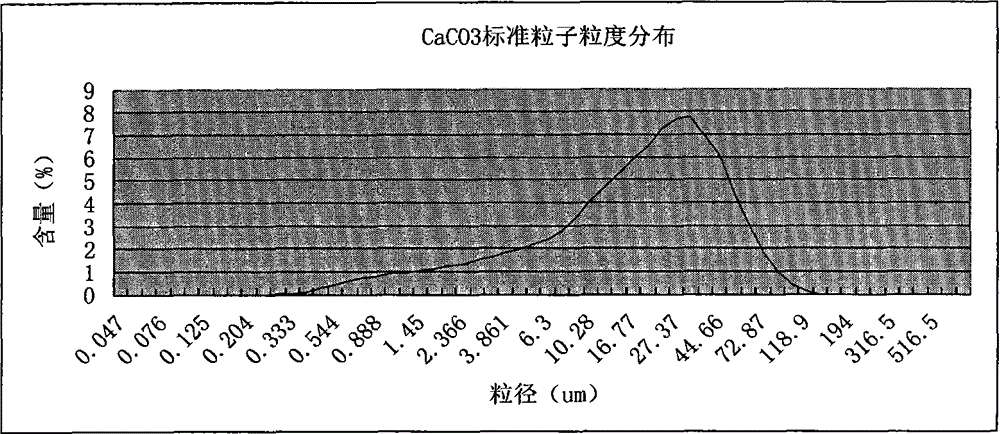

[0030] Example 2, the test of particle size image 3 shown

[0031] Using standard CaCO 3 Particle configuration solution, and use the modified particle spectrum inversion algorithm to compare the test results. Known standard CaCO 3 The median particle size of the particle solution is 17.9um, and the measured value by the software is 18.2um.

example 3

[0032] Example 3, the test of ions Figure 4 shown

[0033] By selecting appropriate system parameters and measuring samples with different concentrations, an approximate linear relationship between spectral line intensity and concentration is obtained. In the 422.67nm band Ca signal intensity and solution concentration diagram (see Figure 4 ), the Ca concentration is 0.97ppm-250ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com