Sapphire wafer positioning and tracking method based on circle detection

A sapphire wafer, positioning and tracking technology, applied in the field of visual positioning, can solve problems such as low efficiency and easy statistical errors, and achieve the effects of avoiding measurement steps, low error rate, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

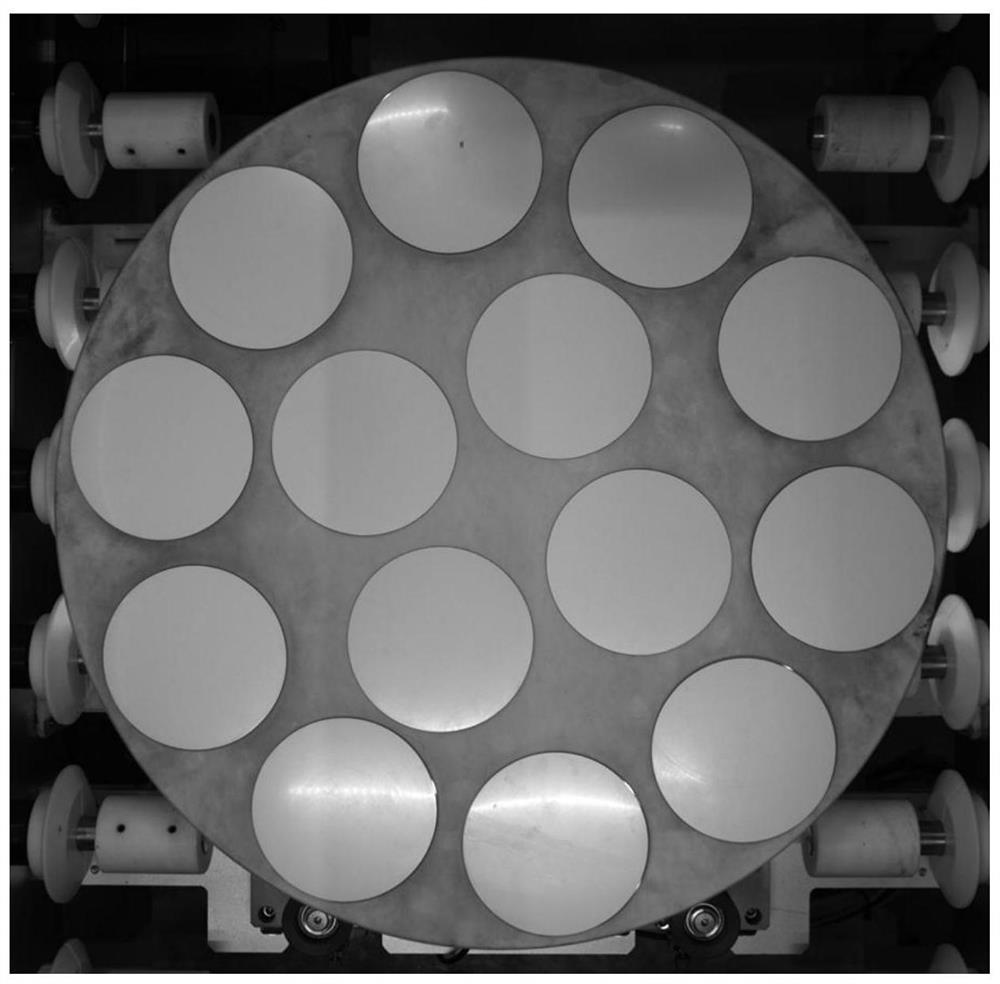

[0068]Such asfigure 1 As shown, the present invention is based on a circular detection of sapphire wafer positioning tracking objects as a ceramic disk and an interior of the internal 4 tablets above the outside.

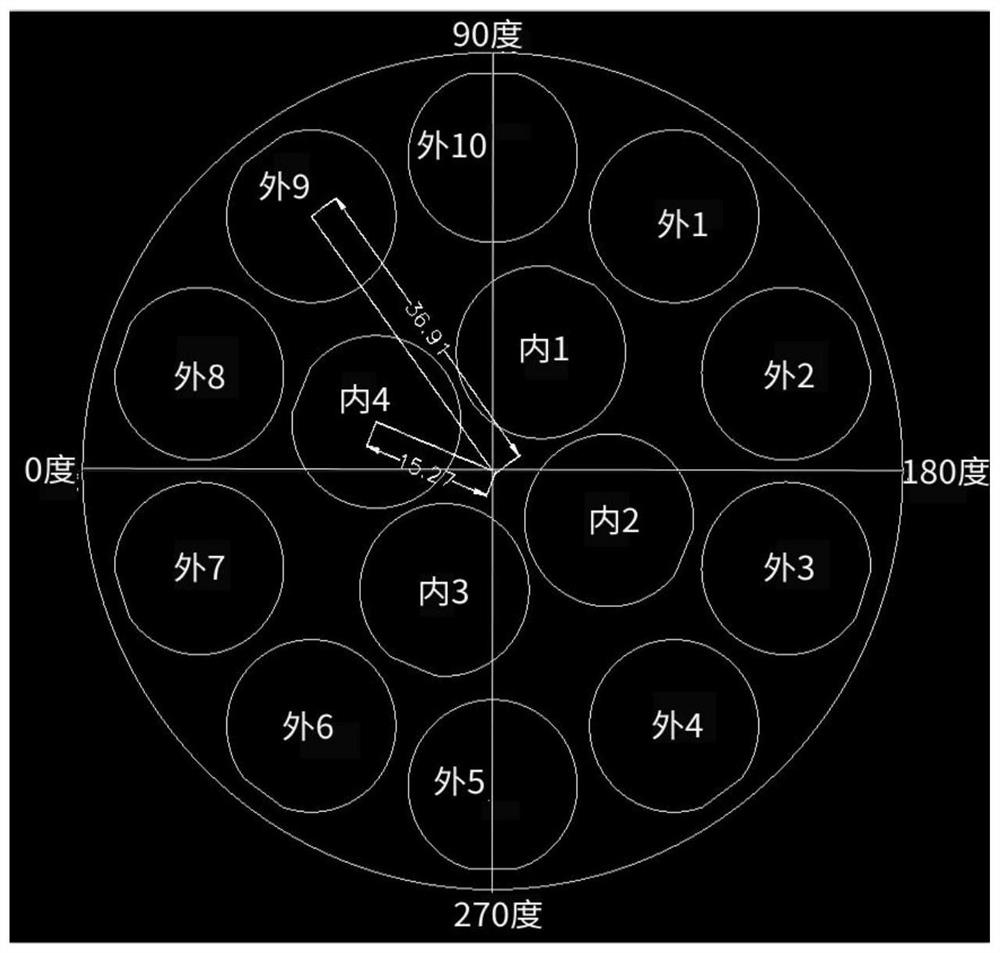

[0069]figure 2 The sequential diagram of a sapphire wafer positioning tracking and sapphire sheet is shown in the present invention.

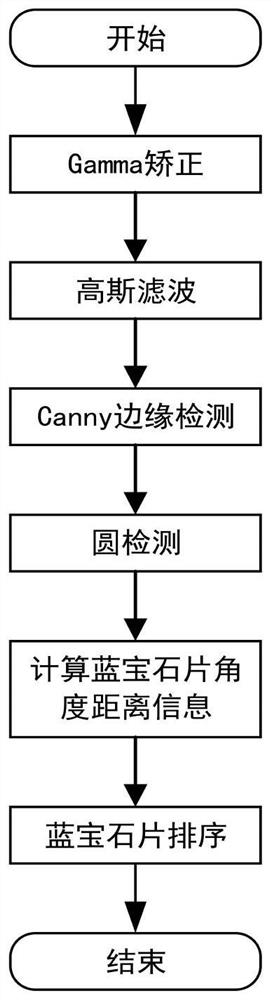

[0070]image 3 The flow chart showing the positioning tracking algorithm based on a round-detected sapphire wafer based on a circular detection.

[0071]Figure 4 The present invention is shown as a circularly detected sapphire wafer positioning tracking method, including: S01, calibration: acquisition single calibration board image and corresponding robot end clamp position information for calibration, to obtain a camera coordinate system and robot coordinate system Relationship matrix;

[0072]The specific steps of S01 are:

[0073]S01-1, mounting the industrial camera on the bracket above the ceramic dish, ensuring that the ceramic disk image can be tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com