Nondestructive testing system and nondestructive testing method based on pseudo-random coding

A pseudo-random coding and non-destructive testing technology, applied in the field of non-destructive testing, can solve the problems of detection signal attenuation, influence of coil impedance, difficulty in ensuring effective work, etc., and achieve the effect of maintaining stability, detection accuracy and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

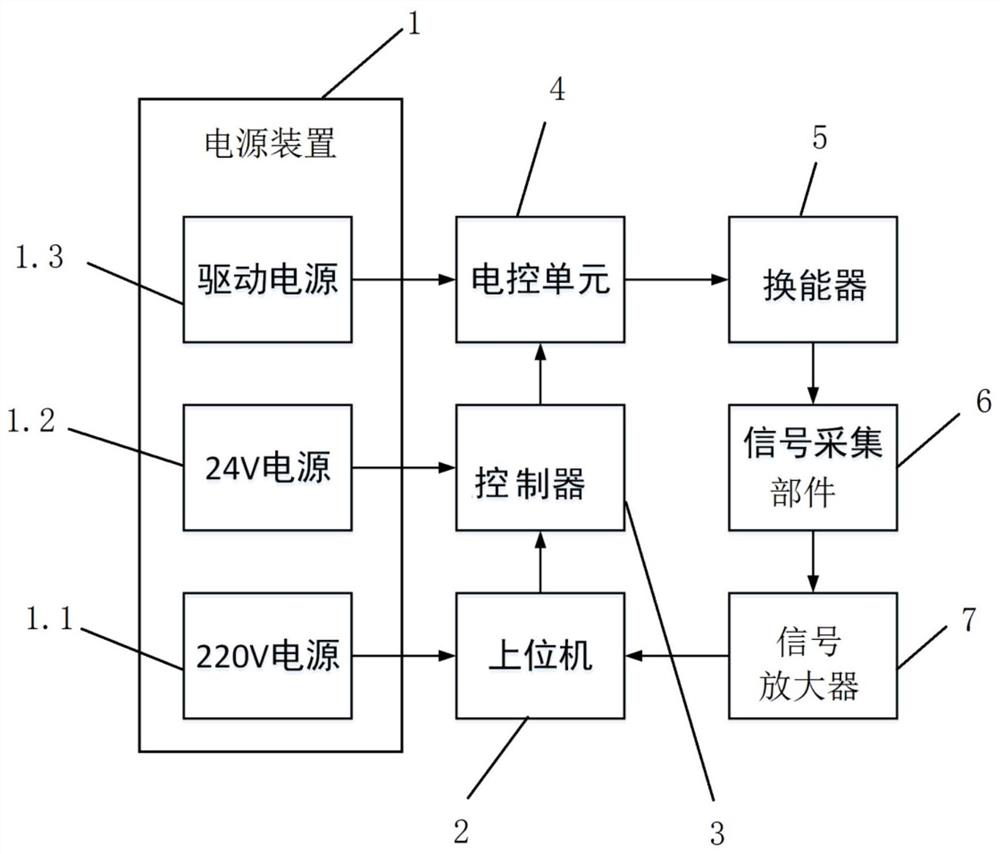

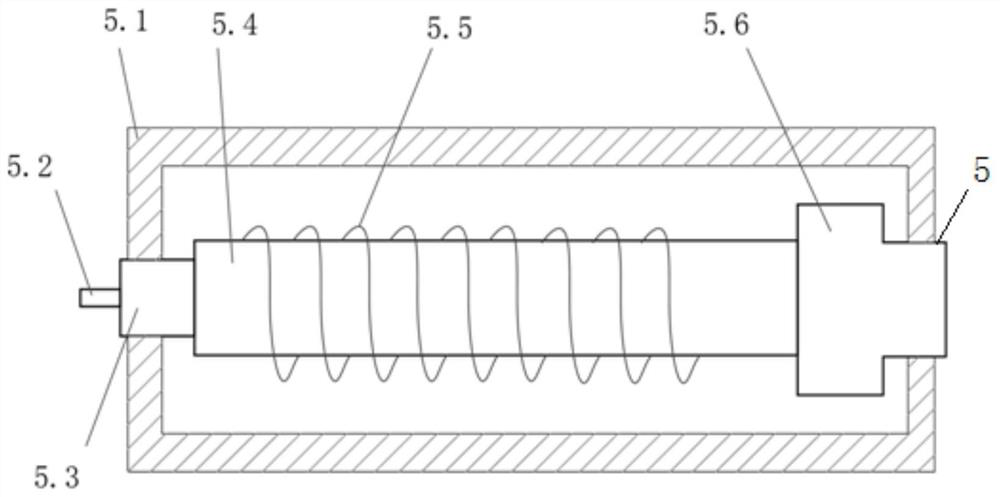

[0038] A non-destructive testing system based on pseudo-random codes, see figure 1 , including a power supply unit 1, a host computer 2, a controller 3, an electric control unit 4, a transducer 5 and a signal acquisition component 6, and the host computer 2, the controller 3 and the electronic control unit 4 are all connected with the power supply unit 1 Electrical connections, details are as follows:

[0039] The power supply device 1 includes a 220V power supply 1.1, a 24V power supply 1.2 and a drive power supply 1.3, the 220V power supply 1.1 is electrically connected to the upper computer 2, and supplies power to the upper computer; the 24V power supply 1.2 is electrically connected to the controller 3, and provides power to the controller. Power supply: the drive power supply 1.3 is electrically connected to the electronic control unit 4 to supply power to the electronic control unit.

[0040]The upper computer 2 includes a shift register that can generate a pseudo-rand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com