Automobile plate laser cutting automatic typesetting and drawing method and system

A technology of laser cutting and automatic typesetting, applied in the field of sheet metal cutting, can solve problems such as low efficiency and waste of raw material sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

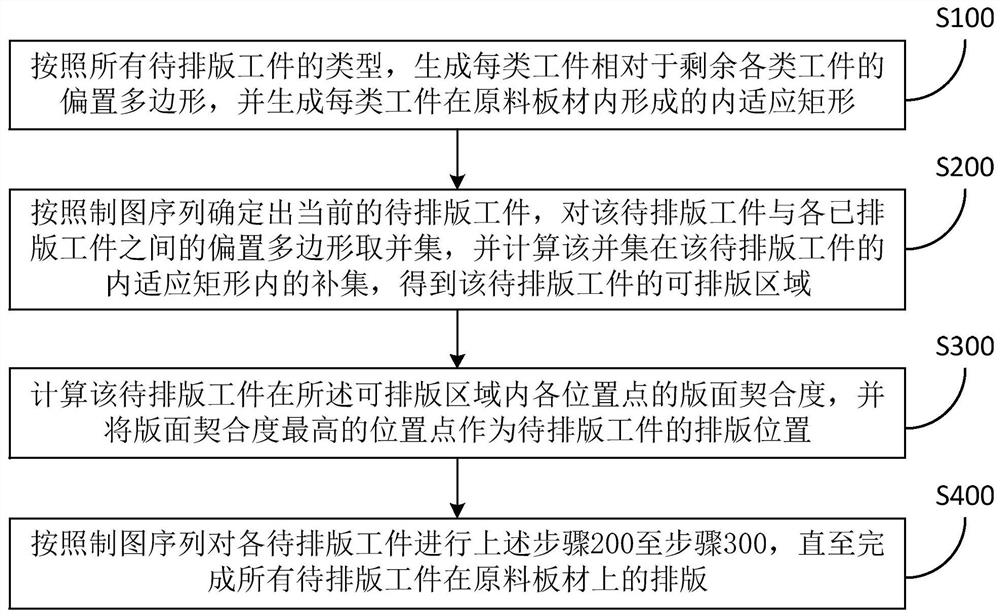

[0097] Refer below Figure 1-Figure 18 The embodiment of the automatic typesetting and drawing method for laser cutting of automobile panels disclosed in this application is described in detail. Such as figure 1 As shown, the method disclosed in this embodiment includes steps 100 to 400 as follows.

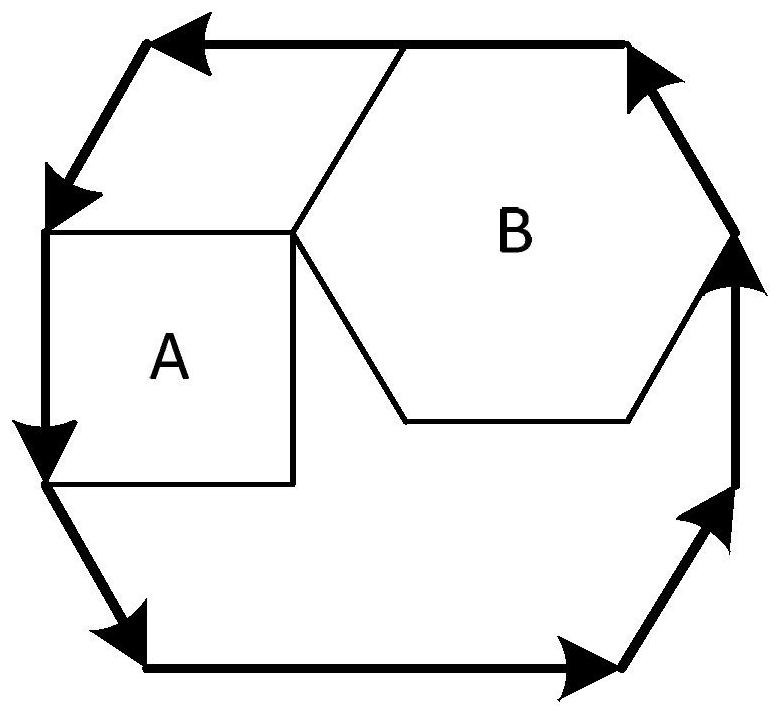

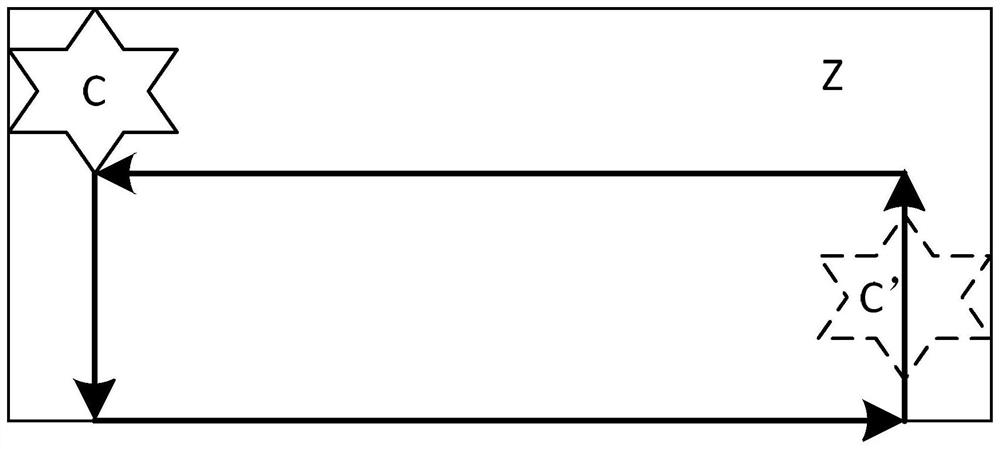

[0098] Step 100, according to the types of all workpieces to be typeset, generate offset polygons of each type of workpiece relative to the remaining types of workpieces, and generate inner adaptation rectangles formed by each type of workpiece in the raw material sheet.

[0099]When the production demand is issued, it is possible to know the types of auto workpieces (auto parts) that need to be produced, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com