Nuclear power plant steam generator blowdown system waste resin cleaning and uncontrolling method

A steam generator and sewage system technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve the problems of no data judgment standard, no closed loop of process, and formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

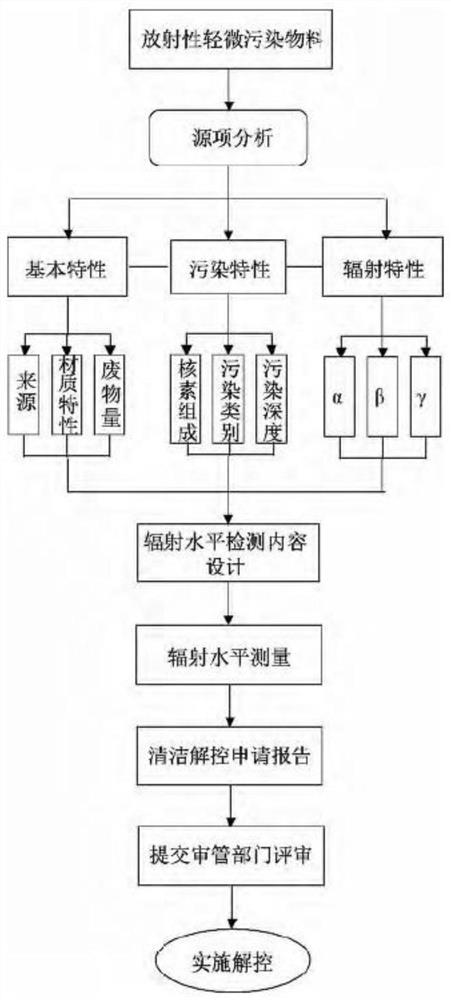

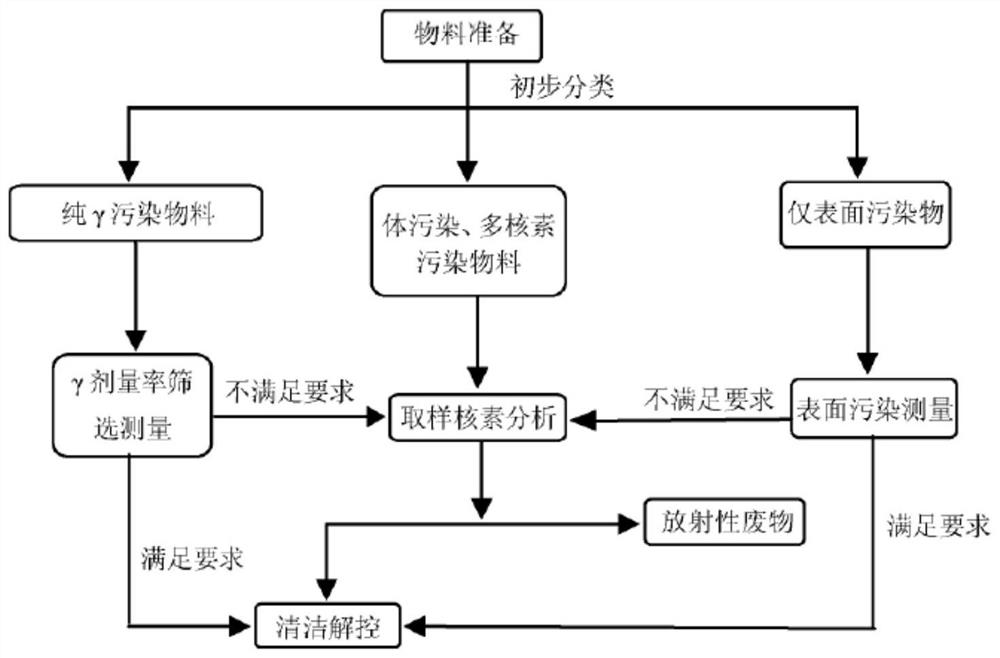

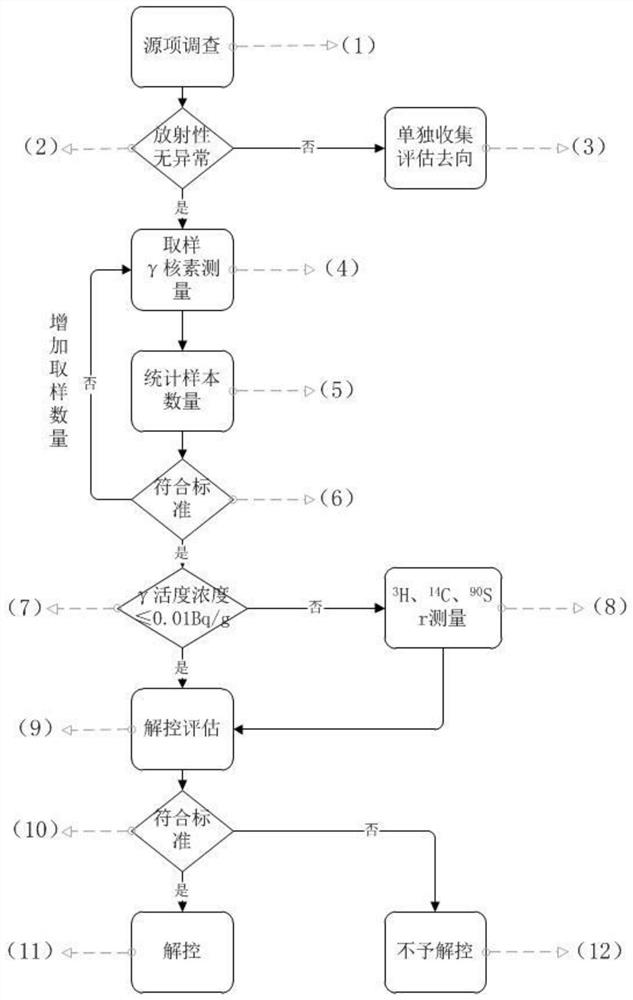

[0076] Such as image 3 A method for cleaning and releasing waste resin in a nuclear power plant steam generator blowdown system includes the following steps:

[0077] Step 1: Source Term Investigation

[0078] By investigating the operation of each monitoring channel of the nuclear power plant and the radioactivity level of the secondary circuit, the leakage of the steam generator and the radioactivity of the sewage are known, and the radiation monitoring of the waste resin replacement and barreling of the steam generator sewage system is used to verify the steam generator U. Integrity of the tube barrier, including the following investigations:

[0079] 1.1 Investigate the operation of the steam generator sewage γ activity monitoring channel, the condenser β activity monitoring channel, and the N16 monitoring channel for detecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com