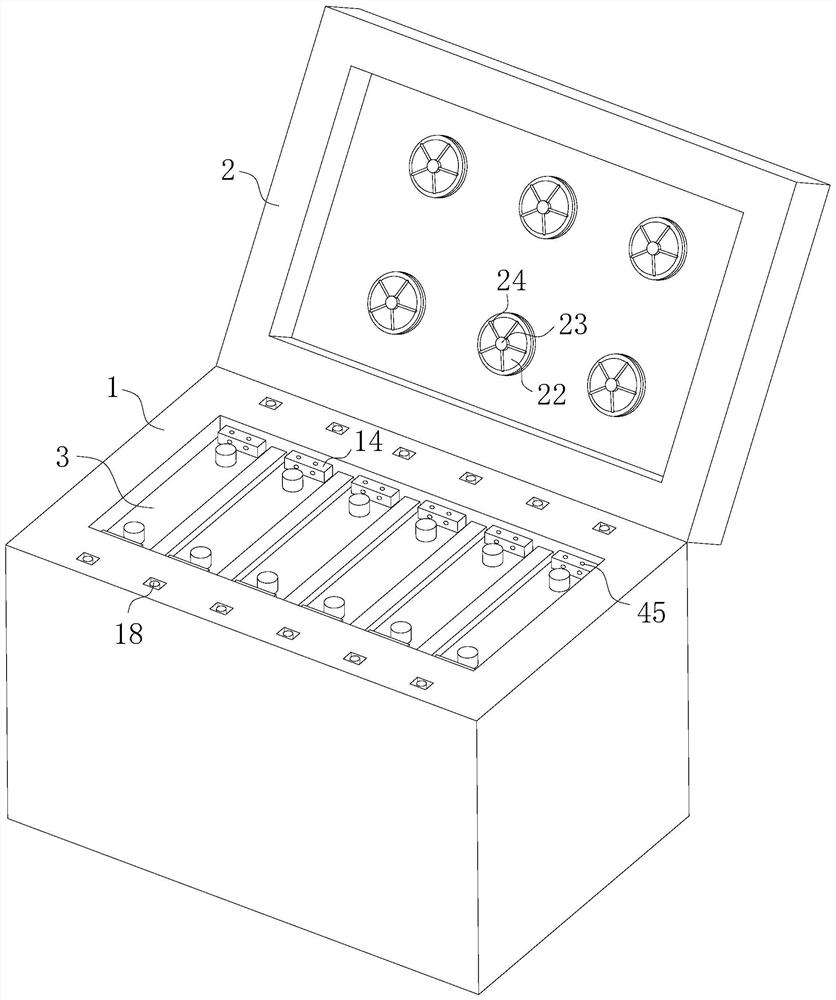

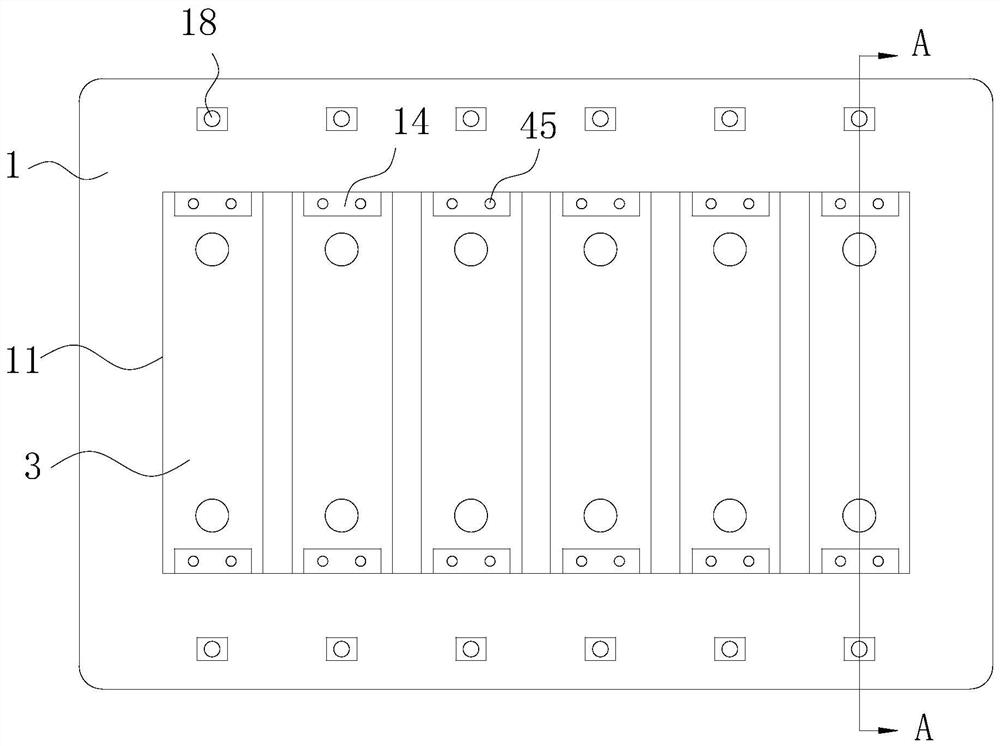

Light vehicle battery management system device

A battery management system and light-duty vehicle technology, applied in the direction of secondary batteries, battery temperature control, battery pack components, etc., can solve the problems of increased internal friction, easily damaged batteries, increased replacement time and cost, etc., to facilitate replacement, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

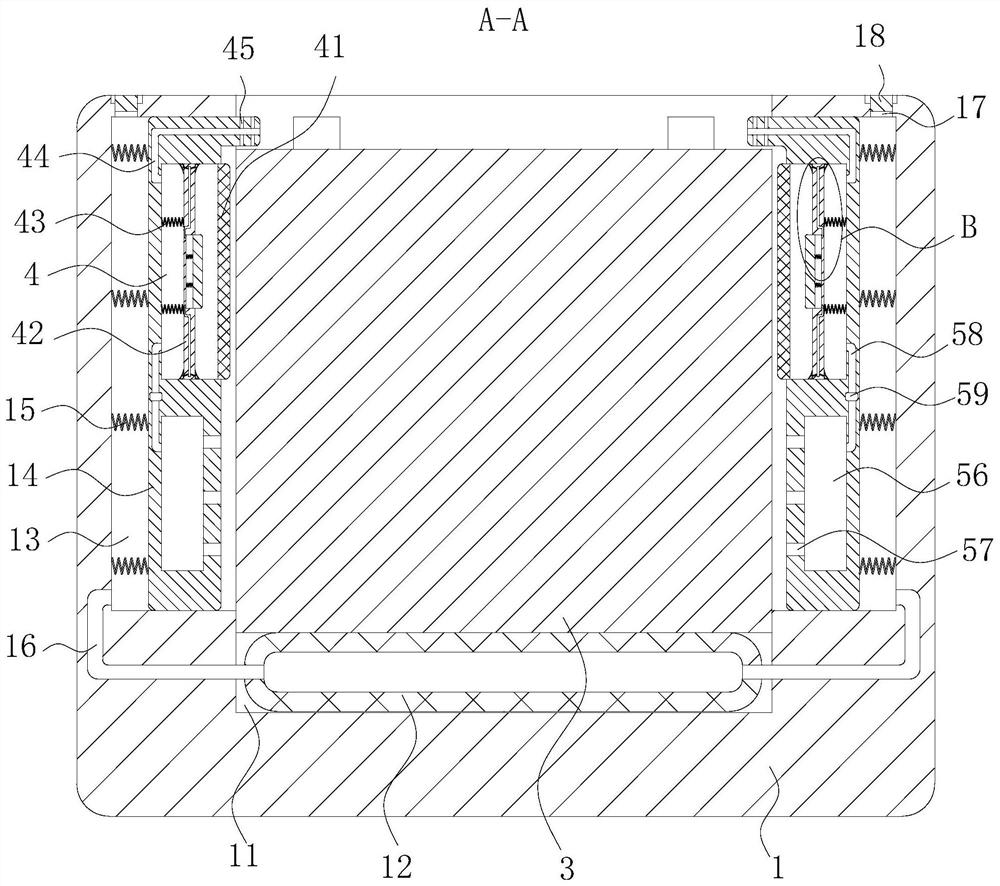

[0028] As an embodiment of the present invention, an end of the through hole 21 away from the sealing cover 22 is fixed with a breathable membrane 26; during operation, as the working time of the battery box increases in the vehicle body, a large amount of dust is easily accumulated on the surface of the box cover 2, When the temperature in the battery box 1 rises, the edge of the sealing cover 22 is bent toward the direction close to the single battery 3, and the hot air is sprayed from the through hole 21 to clean the surface of the box cover 2, and the ventilation film 26 is provided to prevent the partial lifting The dust entering the battery box 1 through the through hole 21 affects the normal working environment and service life of the battery, thereby improving the dustproof and waterproof function of the battery box.

[0029] As an embodiment of the present invention, a sliding groove 4 is formed on one side of the sliding plate 14 relative to the single battery 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com