A cross-mechanical vibrating wolfberry harvester

A technology of mechanical vibration and harvesting machine, which is applied in the direction of agricultural machinery and implements, picking machines, harvesters, etc., and can solve problems such as hand injury, affecting the harvesting effect of wolfberry, and vibration damage to the main or secondary branches of wolfberry. , to achieve the effect of changing the number of beats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

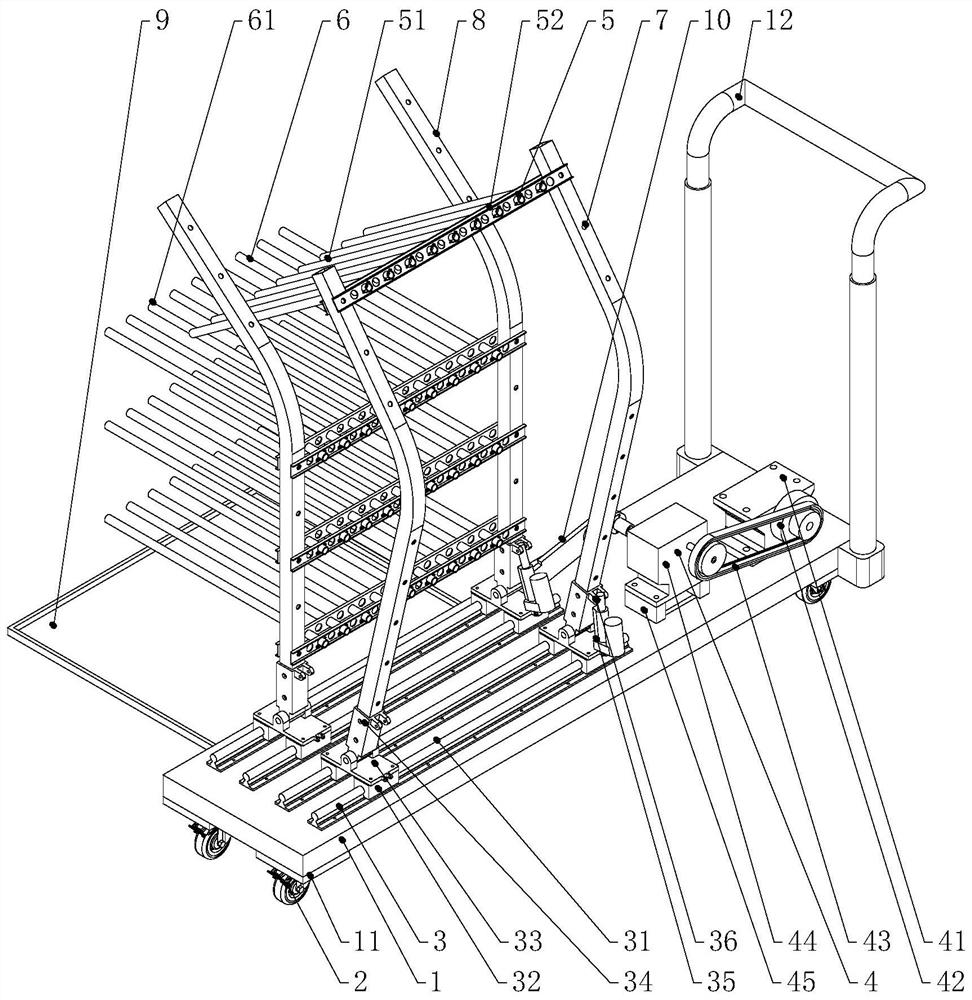

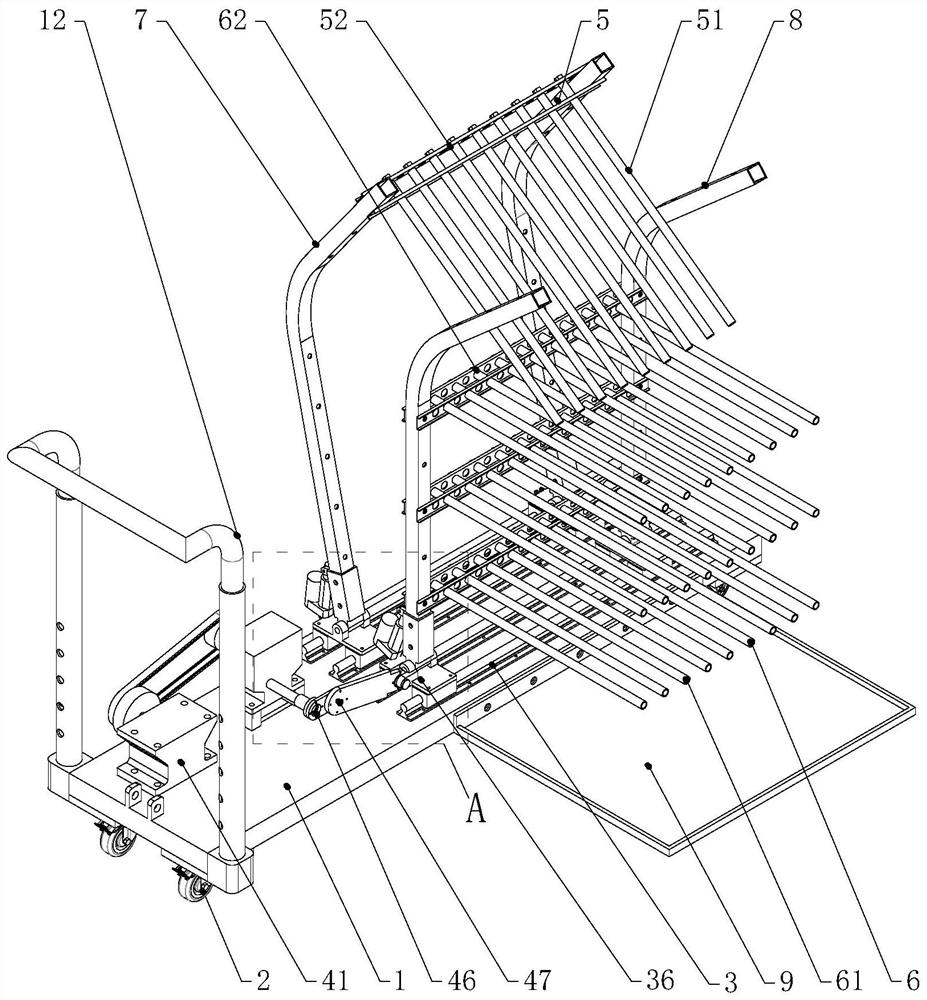

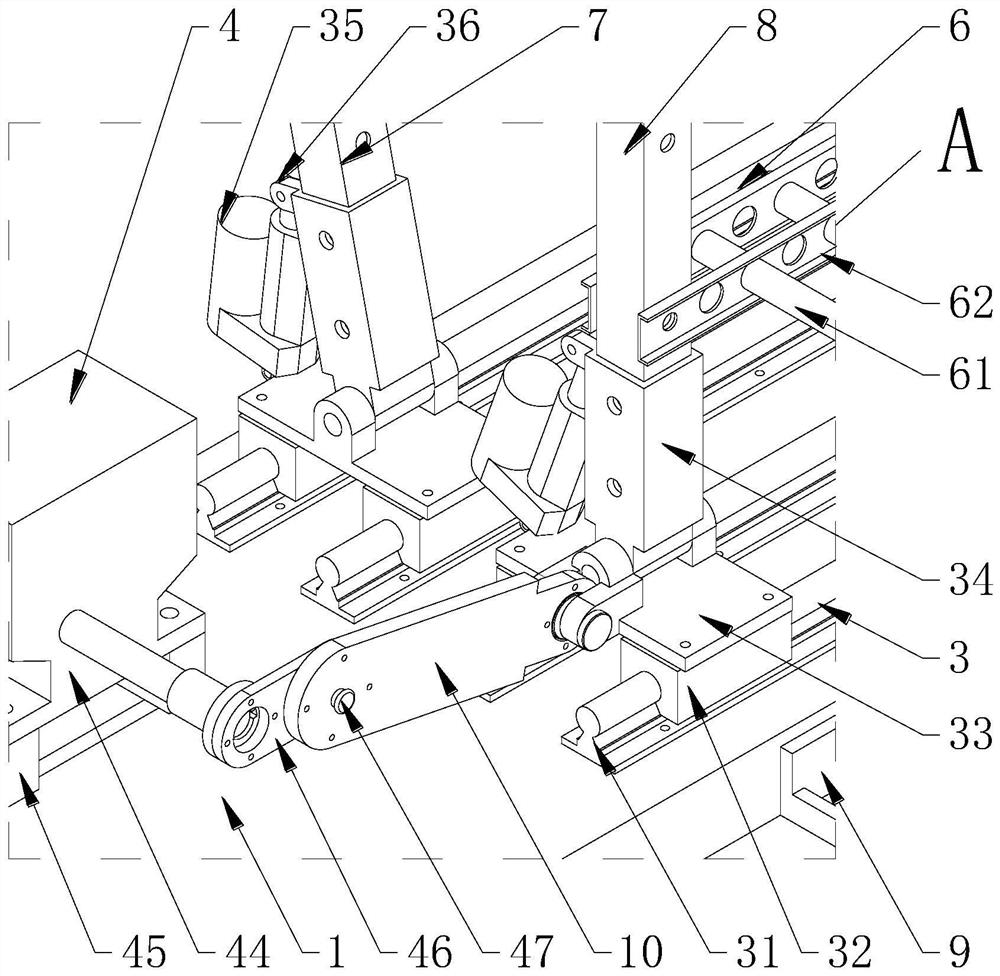

[0031] Such as Figure 1 ~ Figure 4 The shown embodiment of the present invention includes: a bottom plate 1, a universal wheel set 2, two sets of linear sliding sets 3, a vibrating set 4, a clamping finger row 5, a shaking finger row 6, a clamping row square tube 7, a shaking row Square pipe 8, harvesting basket 9, connecting rod 10 and armrest group 12, wherein the universal wheel group 2 is installed below the bottom plate 1, and two sets of linear sliding groups 3 are fixed on the top of the bottom plate 1 in parallel, one in front of the other, vibrating The unit 4 and the armrest group 12 are also fixed on the top of the base plate 1; one end of the connecting rod 10 is pinned to the crank 46 of the vibration unit 4, and the other end is hinged to a sliding base 33 in the linear sliding group 3 in front; two clamps Hold row square tube 7 and insert in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com