Fluorine purification device and method

A purification device and fluorine gas technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of poor purification effect, difficult to fully contact and react with fluorine gas, and achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

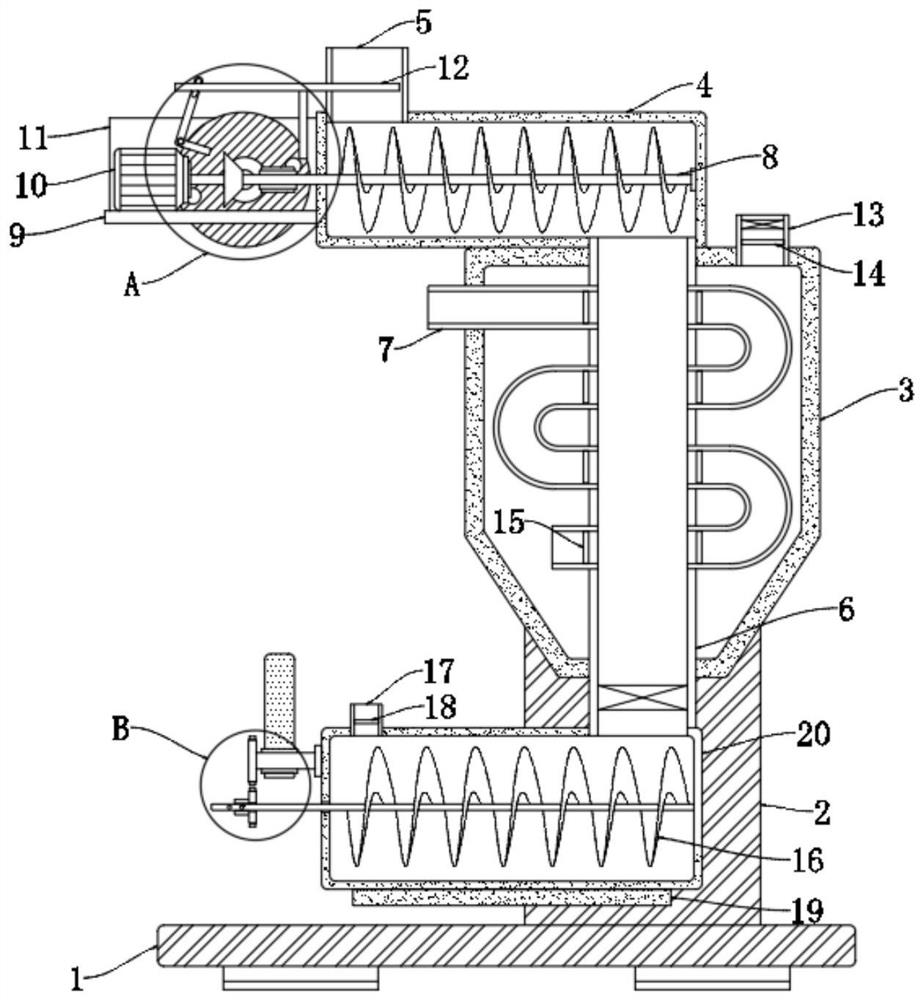

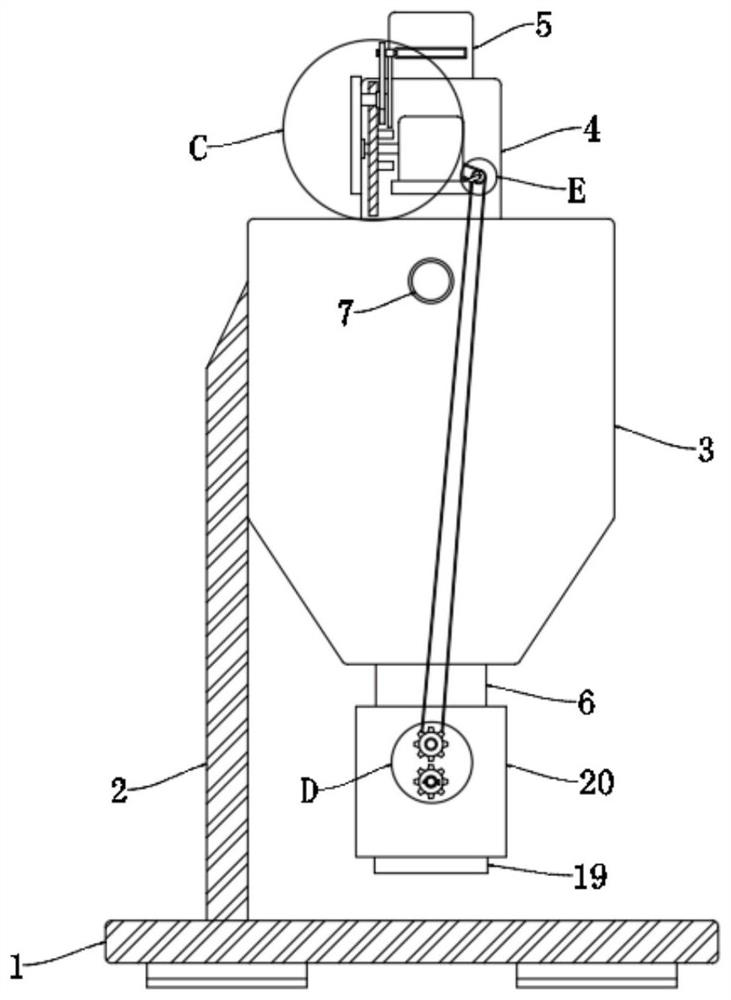

[0039] Purification device of a fluorine gas, such as Figure 1 ~ 7 As shown, the apparatus includes a base 1, a support plate 2, a renewal 3, a first air pipe 13, a first filter 14, a first valve, a feed mechanism, and a heat treatment mechanism.

[0040] The base 1 is fixedly connected to four support bars. The top is fixedly connected to the support plate 2, and the support plate 2 side walls above the base 1 are fixedly connected to the reactor 3, and the top of the reactor 3 is provided with the first inner communication with the reactor 3. The air pipe 13, the first air pipe 13 is provided with a detachable first filter 14 for removing dust and impurities in the fluorine gas, and the first air pipe 13 is provided with a first valve, the top of the reactor 3 and the progress The material is connected, and the bottom of the reactor 3 is provided, and a heat treatment mechanism is provided on the base 1.

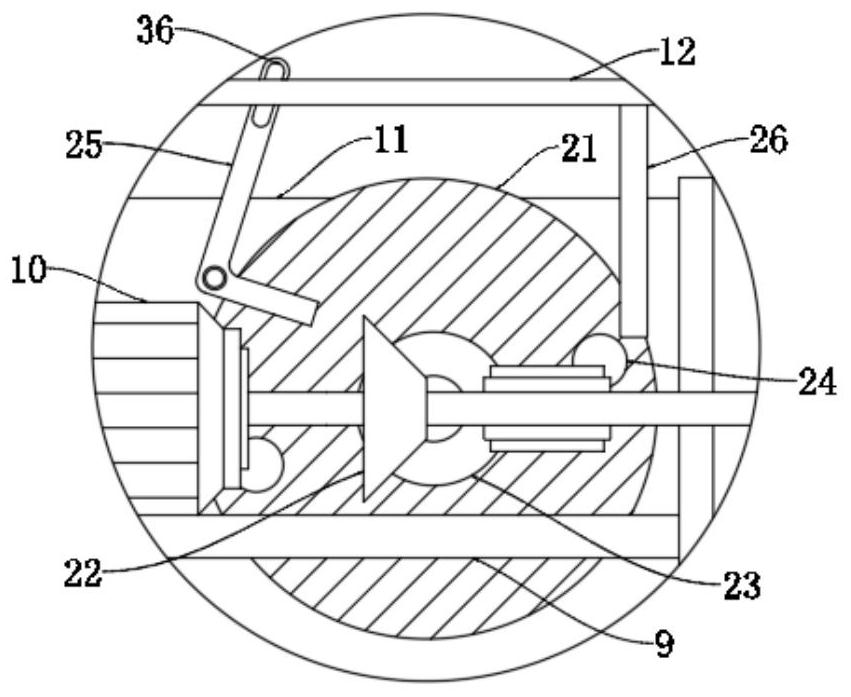

[0041] The feed mechanism is as follows:

[0042] The transfer cartridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com