Organic fertilizer processing device

A processing device and organic fertilizer technology, which is applied in the field of organic fertilizer processing devices, can solve the problems of low processing efficiency, shutdown and discharge, inability to disperse and mix various materials, etc., and achieve the effect of high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

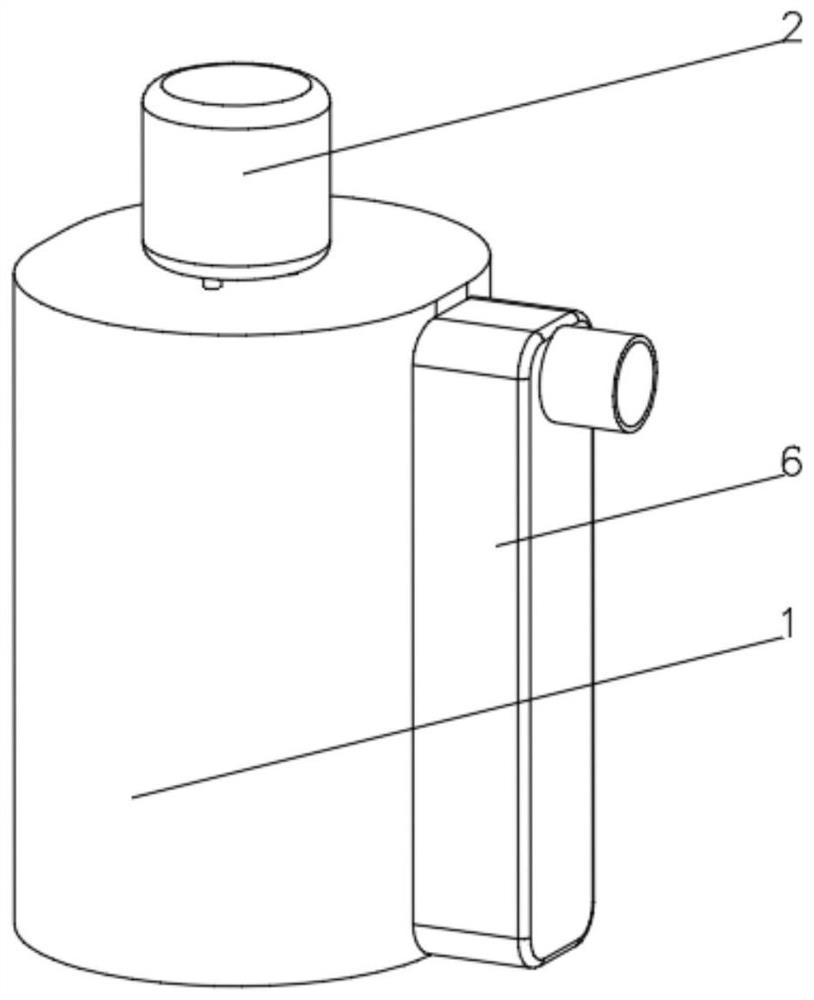

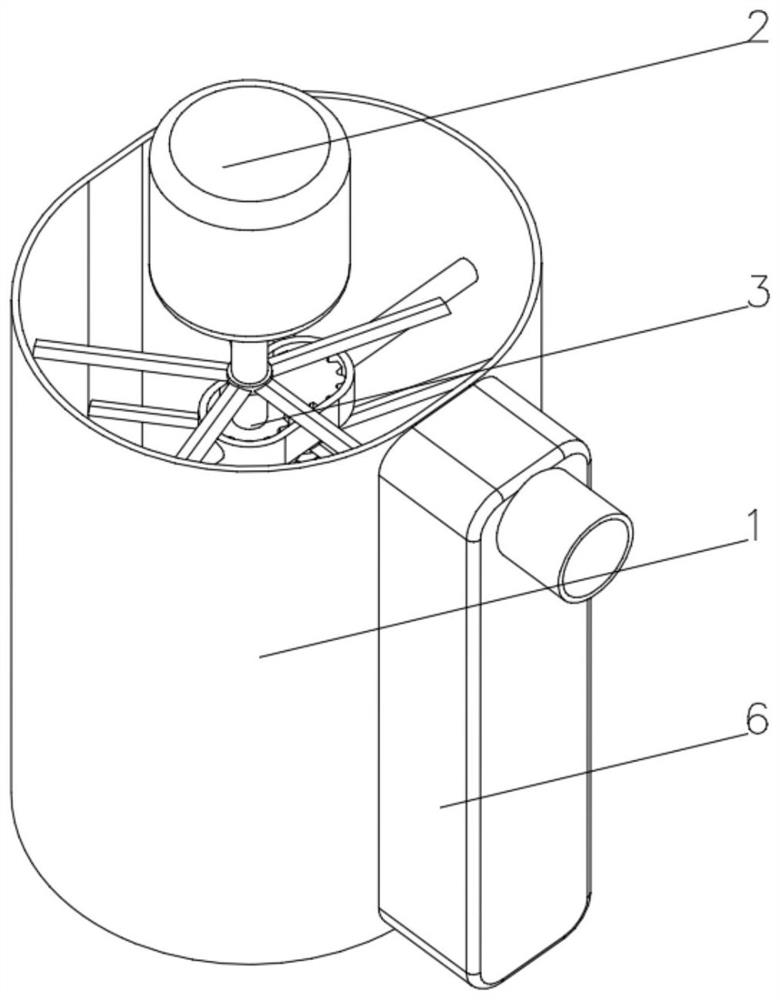

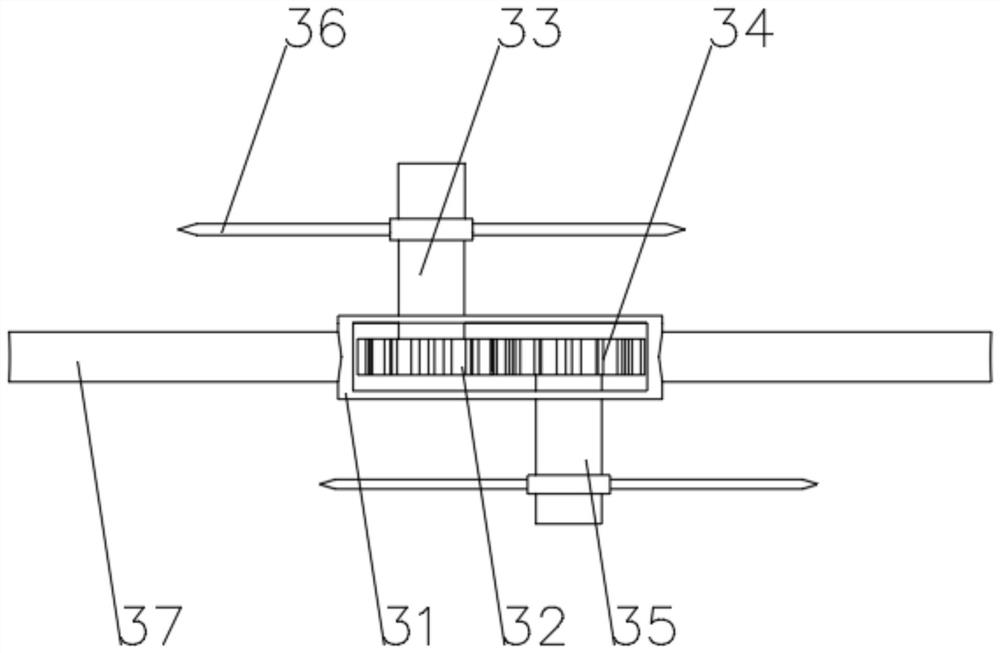

[0038] see Figure 1-4, the present invention provides a technical solution: an organic fertilizer processing device, comprising a processing cylinder 1, a driving motor 2 is fixedly connected to the top of the processing cylinder 1, and a driving shaft of the driving motor 2 runs through the top of the processing cylinder 1 and is fixedly connected to a stirring device 3 The bottom of the inner wall of the processing cylinder 1 is provided with a discharge channel 4, and the end of the stirring device 3 away from the driving motor 2 is fixedly connected with a screw feed roller 5, and the end of the screw feed roller 5 away from the stirring device 3 extends to the inside of the discharge channel 4 and is connected to the inside of the discharge channel 4. The inner wall of the discharge channel 4 is slidingly connected, and the end of the discharge channel 4 away from the screw feed roller 5 extends to the outside of the processing cylinder 1 and communicates with the dischar...

Embodiment 2

[0041] see Figure 1-8 On the basis of Embodiment 1, the present invention provides a technical solution: the discharge device 6 includes a fixed outer cylinder 61, the inner wall of the fixed outer cylinder 61 is fixedly connected with a spiral heating wire 62, and the inside of the spiral heating wire 62 is fixedly connected with a fixed inner cylinder 63, the inner wall at one end of the fixed inner cylinder 63 is fixedly connected with a dividing plate 64, and one side of the dividing plate 64 is provided with a dividing hole 65, and the top side of the fixed inner cylinder 63 is connected with a discharge pipe 66, and the bottom of the inner wall of the fixed inner cylinder 63 is connected to the discharge pipe. The part corresponding to 66 is provided with a rotary valve 67. The rotary valve 67 includes a guide cylinder 671. A feed port 672 is provided on one side of the guide tube 671. A rotary handle 673 is penetrated and rotatably connected to the side of the guide tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com