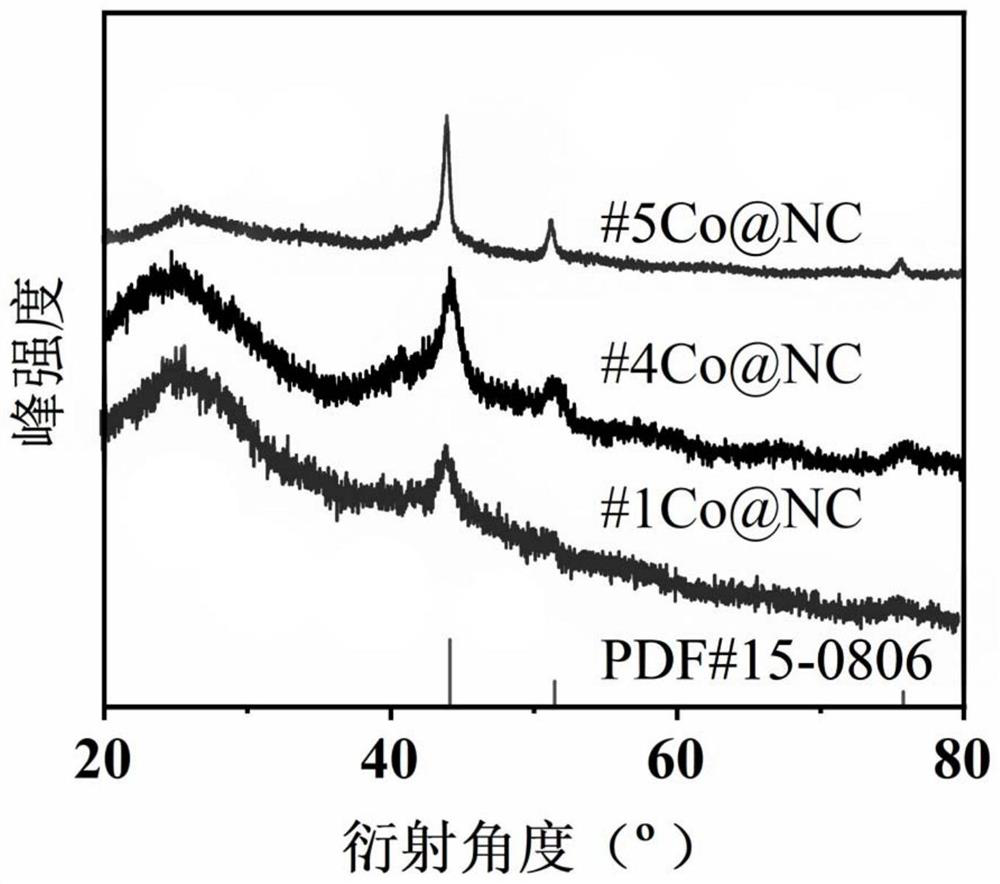

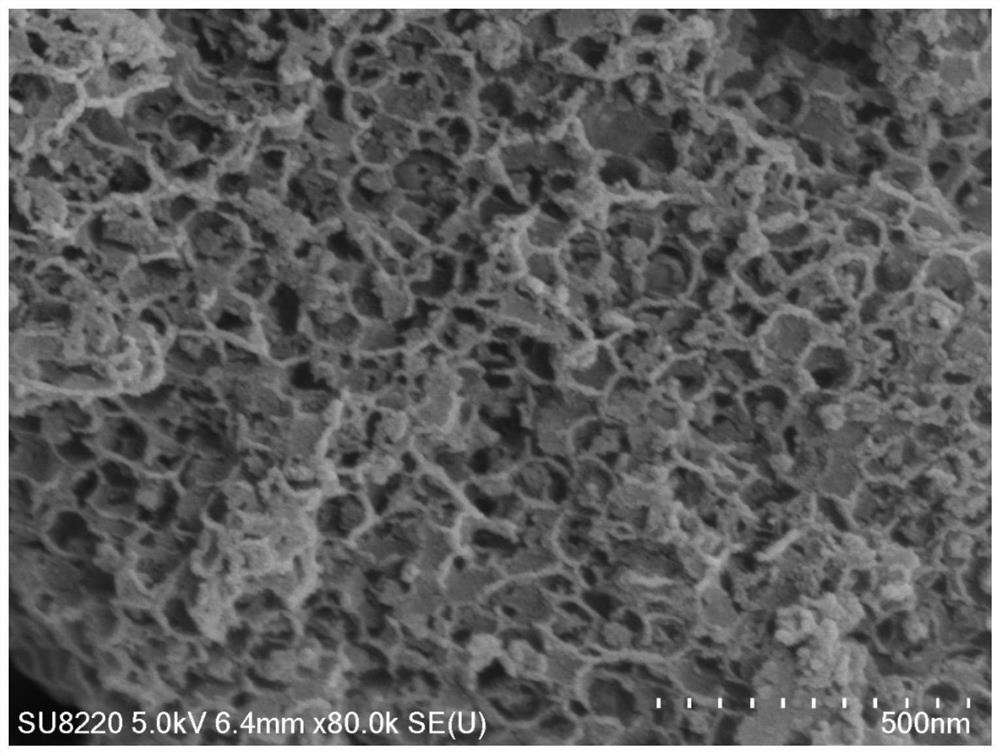

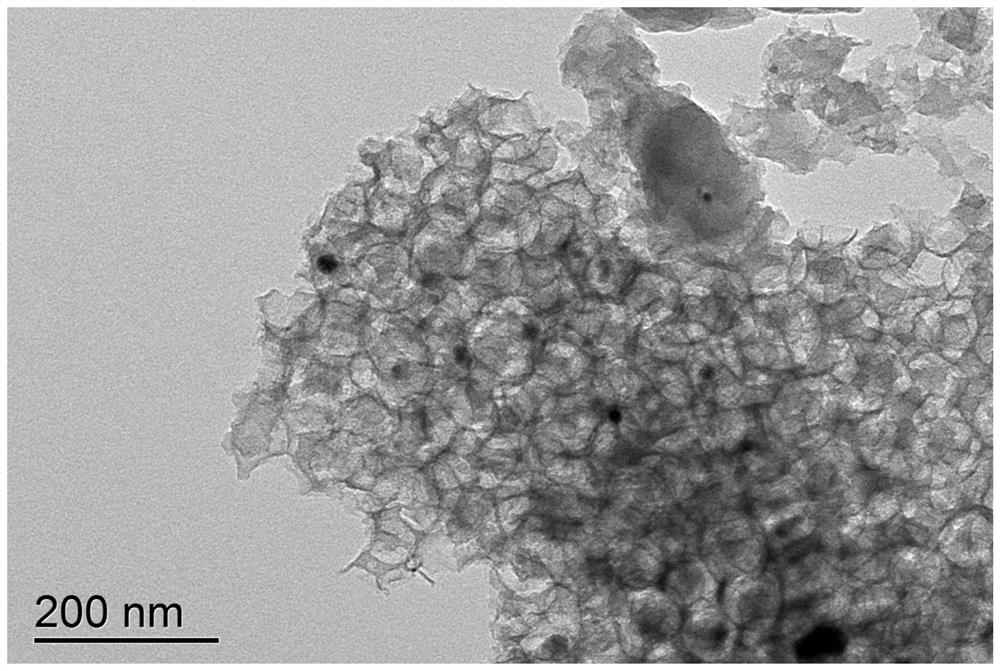

MOFs derived three-dimensional hierarchical pore Co/NC composite material and preparation method thereof

A composite material and multi-level pore technology, which is applied in the field of porous materials, can solve the problems of step limitation and application, and achieve the effect of low cost, good practical application value, and improved catalytic reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing a three-dimensional hierarchically porous Co / NC composite material derived from MOFs, including the following steps:

[0042] (1) 2-methylimidazole (5g) was added in methanol (50mL), dissolved by ultrasonication for 5min to obtain an organic ligand solution; Zn(NO 3 ) 2 ·6H 2 O(1.50g) and Co(NO 3 ) 2 ·6H 2 O (0.20g) was dissolved in methanol (50mL) to obtain a metal salt solution;

[0043] (2) Add the metal salt solution in step (1) to the organic ligand solution to obtain a mixed solution, stir at 25°C for 2 hours to obtain a ZnCo-ZIF suspension, and centrifuge the resulting ZnCo-ZIF suspension at 9500r / min After 8 minutes, the precipitate was taken, and then fully washed with methanol, and dried at 60°C for 12 hours to obtain the ZnCo-ZIF material;

[0044] (3) Weigh 200 mg of the ZnCo-ZIF material obtained in step (2) and disperse it into 5 mL of distilled water, ultrasonicate for 30 minutes to obtain a purple sus...

Embodiment 2

[0051] This embodiment provides a method for preparing a three-dimensional hierarchically porous Co / NC composite material derived from MOFs, including the following steps:

[0052] (1) 2-methylimidazole (5g) was added in methanol (50mL), dissolved by ultrasonication for 5min to obtain an organic ligand solution; Zn(NO 3 ) 2 ·6H 2 O(1.50g) and Co(NO 3 ) 2 ·6H 2 O (0.20g) was dissolved in methanol (50mL) to obtain a metal salt solution;

[0053] (2) Add the metal salt solution in step (1) to the organic ligand solution to obtain a mixed solution, stir at 25°C for 1 h to obtain a ZnCo-ZIF suspension, and centrifuge the resulting ZnCo-ZIF suspension at 9800r / min After 8 minutes, the precipitate was collected, washed thoroughly with methanol, and dried at 60°C for 12 hours to obtain the ZnCo-ZIF material.

[0054] (3) Weigh 200 mg of the ZnCo-ZIF material obtained in step (2) and disperse it into 5 mL of distilled water, ultrasonicate for 30 min to obtain a purple suspension,...

Embodiment 3

[0059] This embodiment provides a method for preparing a three-dimensional hierarchically porous Co / NC composite material derived from MOFs, including the following steps:

[0060] (1) 2-methylimidazole (5g) was added in methanol (50mL), dissolved by ultrasonication for 5min to obtain an organic ligand solution; Zn(NO 3 ) 2 ·6H 2 O(1.50g) and Co(NO 3 ) 2 ·6H 2 O (0.20g) was dissolved in methanol (50mL) to obtain a metal salt solution;

[0061] (2) Add the metal salt solution in step (1) to the organic ligand solution to obtain a mixed solution, stir at 25°C for 12 hours to obtain a ZnCo-ZIF suspension, and centrifuge the resulting ZnCo-ZIF suspension at 6500r / min After 8 minutes, the precipitate was collected, washed thoroughly with methanol, and dried at 60°C for 12 hours to obtain the ZnCo-ZIF material.

[0062] (3) Weigh 200 mg of the ZnCo-ZIF material obtained in step (2) and disperse it into 5 mL of distilled water, ultrasonicate for 30 min to obtain a purple suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com