Elevator landing door intelligent production line

A production line and elevator hall technology, applied in the field of hall door production equipment, can solve the problems of uneven production quality, uneven product quality, and low production efficiency, and achieve the effects of improving production efficiency, reducing labor costs, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

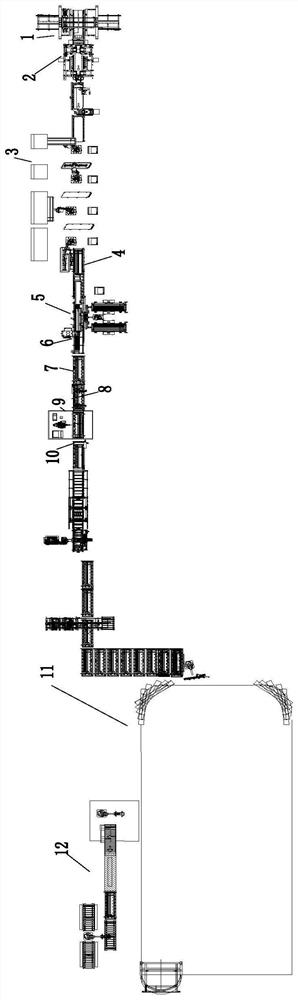

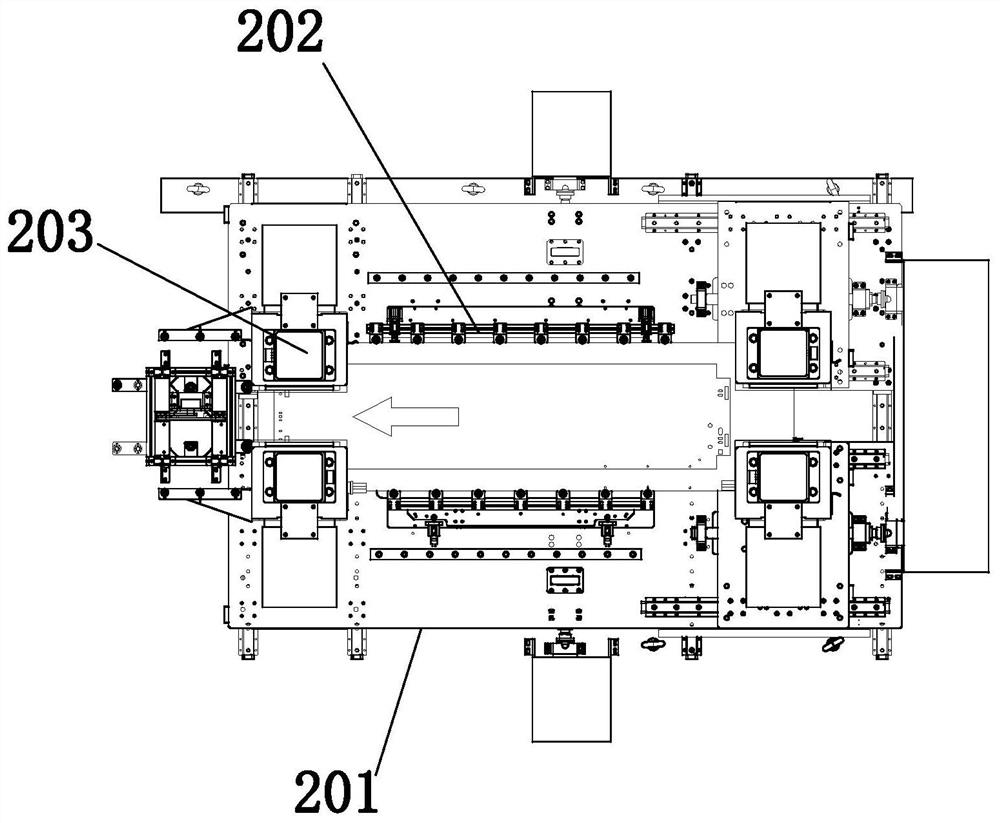

[0032] Example. An intelligent production line for elevator hall doors, consisting of Figure 1 to Figure 11 As shown, it includes automatic reclaiming device 1, automatic positioning punching device 2, bending assembly 3, automatic gluing device 4, reinforcing rib feeding device 5, reinforcing rib spot welding device 6, glue pressing device 7, Door panel four-corner riveting device 8 , door panel arc welding device 9 , paint touch-up stacking device 10 , powder spraying device 11 and packaging device 12 .

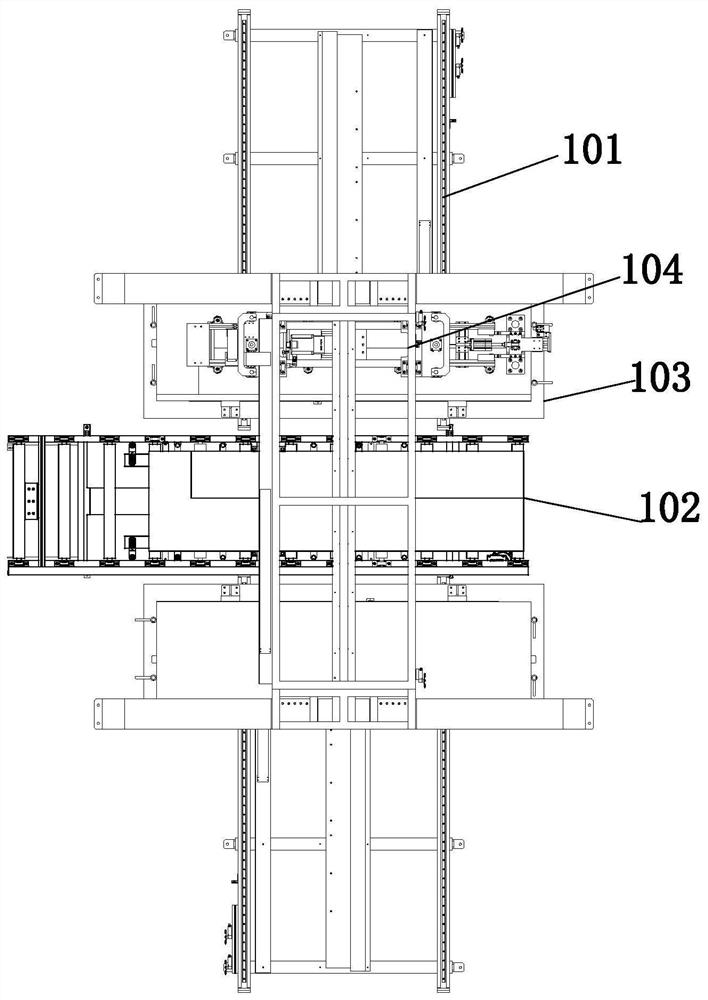

[0033] The automatic retrieving device 1 includes a feeding frame 101, the middle part of the feeding frame 101 is provided with a conveying mechanism 102, the two sides of the conveying mechanism 102 are provided with a feeding mechanism 103, and the top of the feeding frame 101 is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com