Rotary sealing mechanism for fixing center cylinder of stirring barrel

A technology of rotary sealing and sealing mechanism, applied in the direction of engine sealing, cement mixing device, mechanical equipment, etc., can solve the problems of deformation, relaxation and even gap of sealing cover and rotary sealing mechanism, damage of rotary sealing mechanism, affecting sealing effect, etc. To achieve the effect of improving heat preservation and moisturizing, ensuring quality and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

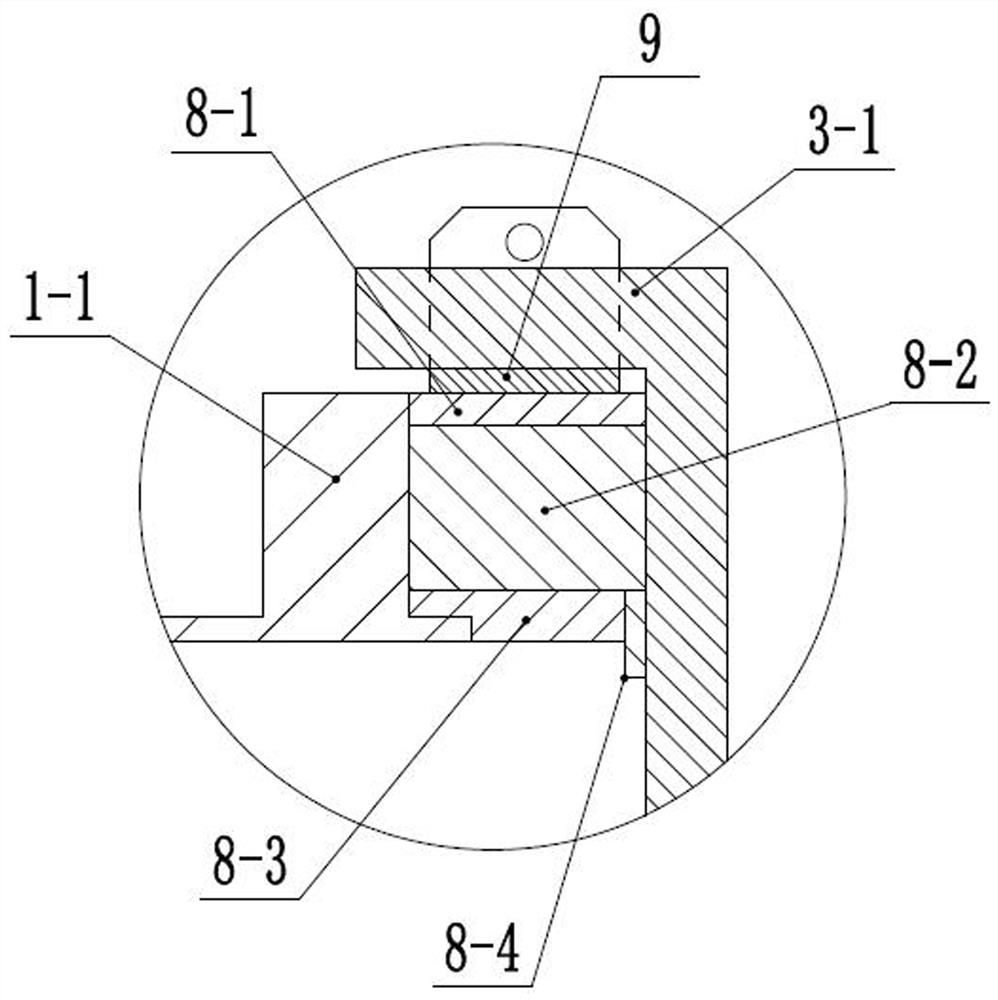

[0048] like image 3 The difference between this embodiment and Embodiment 1 is that an annular hoop 9 is provided on the outer side of the outer ring sealing mechanism 8, and the disconnection of the annular hoop 9 is tightened with bolts, thereby fixing the outer ring sealing mechanism 8 At the end of mixing bucket 1. When using the structure, the surrounding ring 3-1 is located outside the ring hoop 9 and does not directly contact with the outer circular surface of the outer ring 8-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com