Shrimp curve blanking hopper

A technology of dropping hoppers and curves, which is applied in the field of hoppers of material bins, and can solve problems such as inability to change the position and spacing, heavy welding workload, and huge workload of sheet metal cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

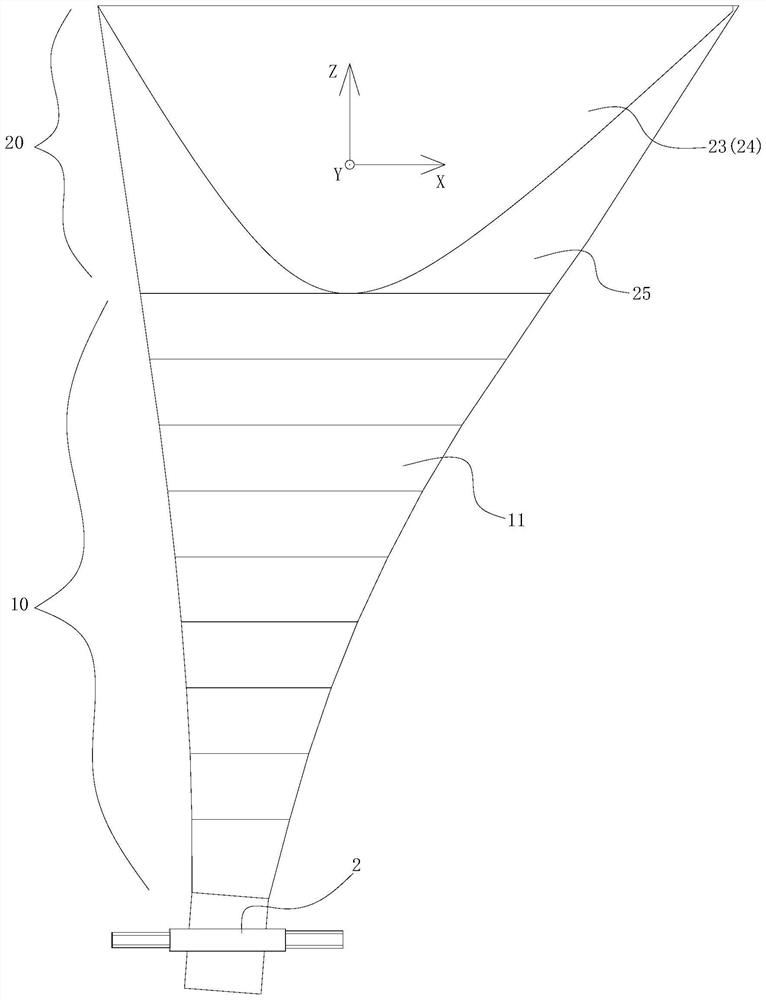

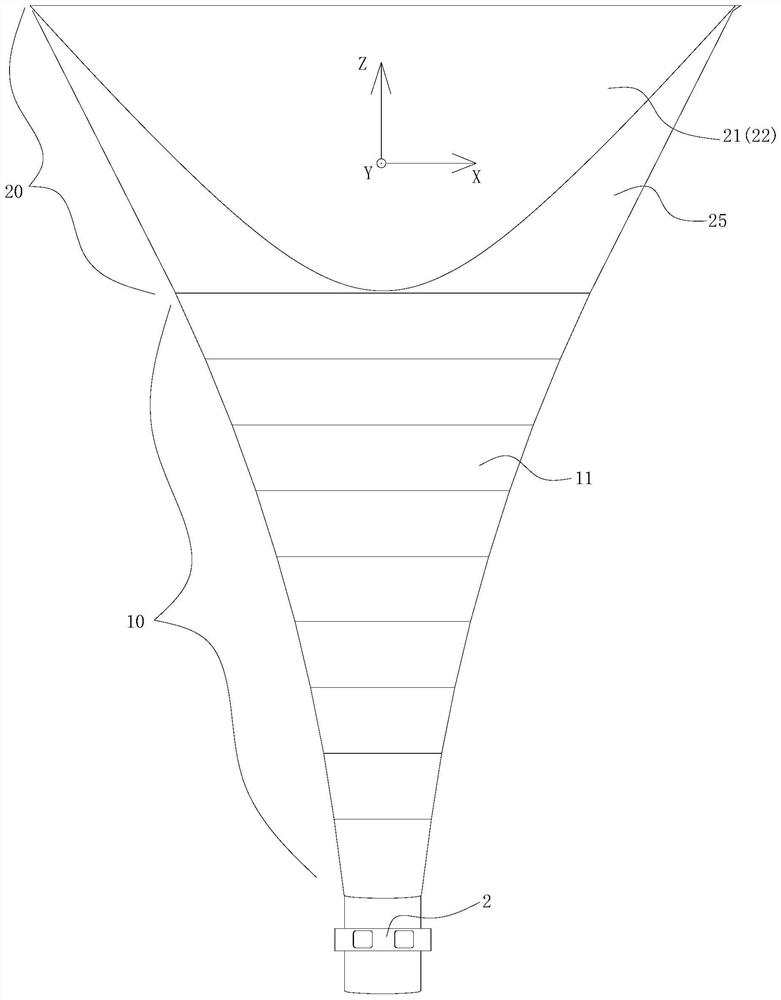

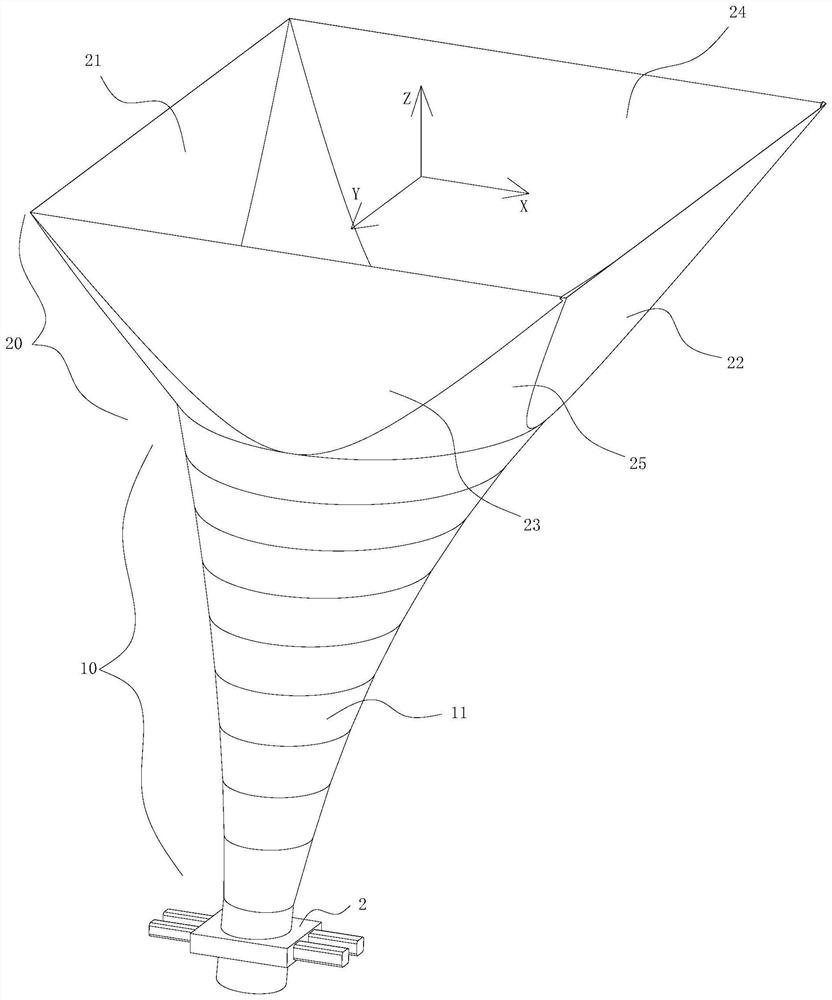

[0011] A curvilinear drop hopper for dried shrimps, comprising a tubular drop hopper 10, the drop hopper 10 is composed of several segmented unit tubes 11 from top to bottom, and the cross-sectional profile of the lumen is circular as a whole and gradually decreases from top to bottom , the upper end of the blanking pipe bucket 10 is connected to the discharge opening of the silo through the upper opening of the transition pipe joint 20 with a circular lower opening. The pipe core of the discharge pipe bucket 10 and / or the transition pipe joint 20 on the upper part of the valve 2 deviates from top to bottom in a direction away from the core of the discharge port.

[0012] In the above scheme, the falling pipe bucket is composed of several segmental unit pipe joints 10 from top to bottom, and the lumen gradually decreases from top to bottom, so that the formed falling pipe bucket 10 presents a shrimp curvilinear shape as a whole; The pipe core of the hopper bucket 10 and / or the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com