Device for ointment packaging

A technology for packaging and ointment, applied in the directions of packaging, transportation and packaging, liquid bottling, etc., can solve the problems of inconvenient filling of ointment, easy dumping, etc., and achieve the effect of simple and convenient feeding and avoiding dumping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

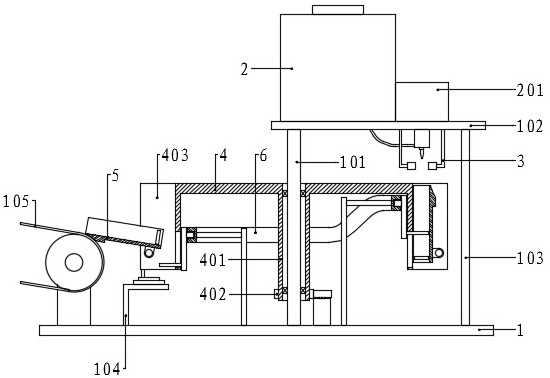

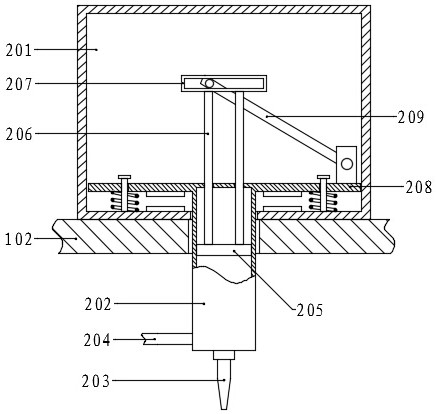

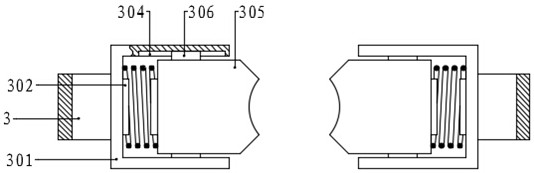

[0057] Please refer to the drawings, the present invention provides a technical solution: a device for ointment packaging, including a base 1, a vertical fixed shaft 101 is fixed in the middle of the top surface of the base 1, and an inclined feeding shaft is provided on the left side of the top surface. Conveyor belt 105, and the side close to the base 1 is lower, the fixed shaft 101 is connected with the turntable 4, the bottom of the turntable 4 is provided with a drive assembly, the top of the fixed shaft 101 is fixed with a fixed plate 102, and the fixed plate 102 is located at the base 1 above the right section, and the outside of the bottom surface is fixed with a vertical fixed rod 103, the bottom of the fixed rod 103 is fixedly connected to the base 1, providing support for the outer section of the fixed plate 102, improving the stability of the fixed plate 102, The medicine storage box 2 is fixed on the left side of the top surface of the fixed plate 102, and the driv...

Embodiment 2

[0074] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that an L-shaped spring frame 703 is fixed on the lower part of the outer surface of the arc-shaped slide plate 701, and the top plate 7 is horizontally slidably connected to the bottom of the arc-shaped slide plate 701, and One end stretches out arc slide plate 701, and is fixed with iron spring plate 704, is provided with spring between spring plate 704 and the vertical section of spring frame 703, is provided with notch 705 on the vertical section of spring frame 703, wherein A mounting plate 603 is fixed on the outside of a vertical bar 602. The position of the vertical bar 602 is staggered from the position of the filling assembly and the feeding conveyor belt 105. The electromagnet 604 and the fourth electromagnet 604 are electrically connected with a power source and a switch.

[0075] The material blocking plate 8 is set as U-shaped, and is slidably connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com