Vertical sewage treatment equipment and process for mud-water separation by air floatation

A sewage treatment equipment and mud-water separation technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

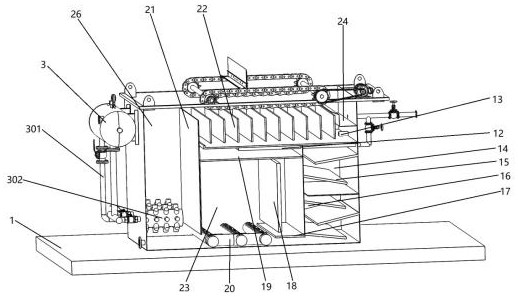

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0025] The invention provides vertical sewage treatment equipment and technology for mud-water separation using air flotation. The equipment adopts air flotation instead of conventional gravity sedimentation, and the oxygen content in the effluent is high. Air flotation is used for mud-water separation, and the whole adopts a three-dimensional design, accounting for The ground area is small; gravity flow is used for sludge return, and power consumption is low. The invention can remove pollutants in sewage efficiently and to a high standard.

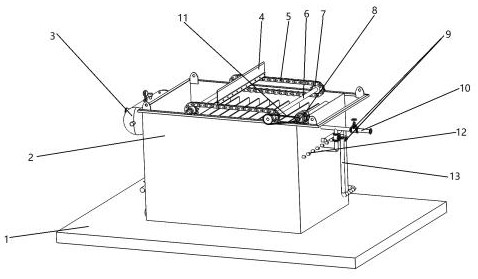

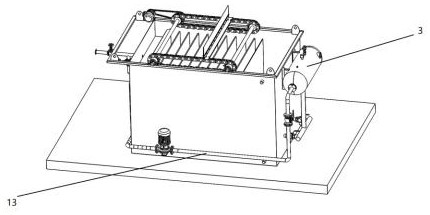

[0026] As an embodiment of the invention, the present invention provides vertical sewage treatment equipment that uses air flotation to separate mud and water, including a box body 2, a microbubble generator 3, a slag scraping mechanism, an anoxic reaction zone 14, and an anaerobic reaction zone 16 , aerobi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap