Preparation method of 1, 1 '-ethylene-2, 2'-dipyridyl dichloride

A bipyridine dichloride and bipyridine technology, applied in the field of chemical synthesis, can solve the problems of long reaction route, high cost, complicated process and the like, and achieve the effects of short reaction route, overcoming long reaction route and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

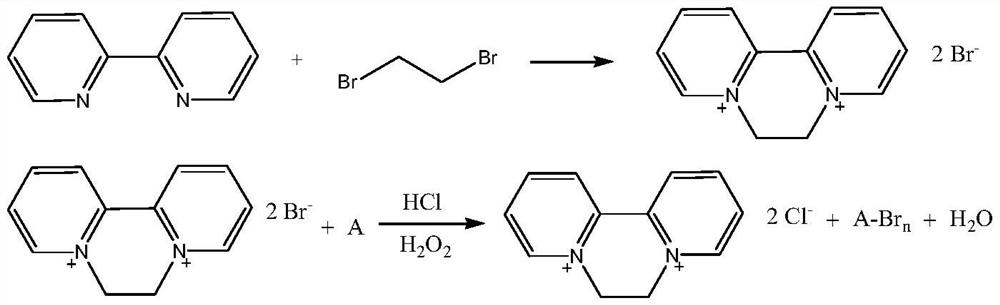

[0042] Add 360g of 2,2'-bipyridine and 3600g of dichloroethane into a dry 5L reactor, start stirring, replace the reactor with nitrogen, slowly raise the temperature to 130°C, raise the reaction pressure to 0.3MPa, keep at 130°C for 48h, and stop the reaction . Sampling analysis showed that the conversion rate of 2,2'-bipyridine was 4.1%, and the selectivity of the product 1,1'-ethylene-2,2'-bipyridine dichloride was 93.0%.

Embodiment 2

[0044] Add 360g of 2,2'-bipyridine and 3600g of dichloroethane into a dry 5L reactor, start stirring, replace the reactor with nitrogen, slowly raise the temperature to 250°C, raise the reaction pressure to 2.8MPa, keep at 250°C for 20h, and stop the reaction . Sampling analysis showed that the conversion rate of 2,2'-bipyridine was 58.2%, and the selectivity of the product 1,1'-ethylene-2,2'-bipyridine dichloride was 89.3%.

Embodiment 3

[0046] Add 360g of 2,2'-bipyridine and 3600g of dichloroethane into a dry 5L reactor, start stirring, replace the reactor with nitrogen, slowly raise the temperature to 290°C, raise the reaction pressure to 3.3MPa, keep at 290°C for 1 hour, and stop the reaction . Sampling analysis showed that the conversion rate of 2,2'-bipyridine was 30.2%, and the selectivity of the product 1,1'-ethylene-2,2'-bipyridine dichloride was 76.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com