Processing aid ACR for PVC sheet high-transparency product

A processing aid and transparent technology, applied in the field of processing aid ACR for PVC sheet high-transparency products, can solve the problems of high cost, low efficiency, cumbersome production process, etc., and achieve the effect of improving quality, convenient use and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

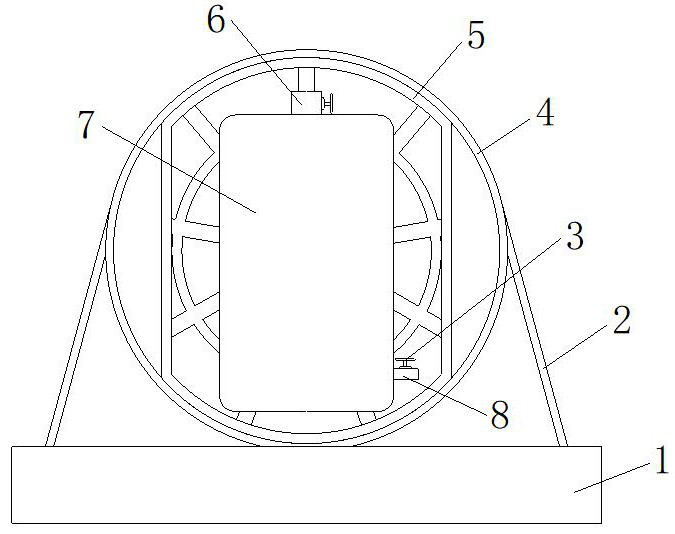

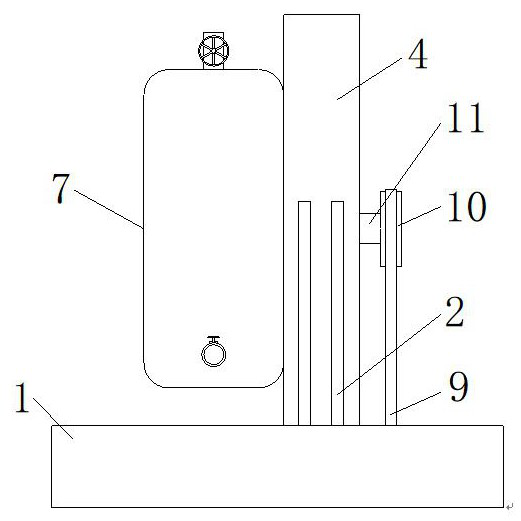

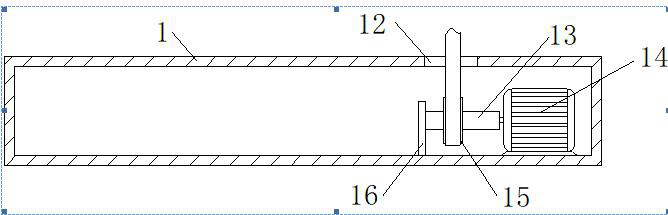

[0026] Such as Figure 1-3 As shown, the embodiment of the present invention provides a PVC sheet high-transparency product processing aid ACR, including the following materials, and each weight part of raw materials is weighed according to the following formula: 70 parts of methacrylates, 10 parts of acrylates, emulsifier 2 parts, the emulsifier is allyl polyether, and the methacrylate, acrylate and emulsifier are put into a reaction tank for polymerization reaction to obtain the processing aid ACR.

[0027] By adding methacrylates, acrylates and emulsifiers into the reaction tank at one time, the reaction temperature is kept at 70-80 degrees Celsius, and the reaction pressure is controlled as normal pressure. The reaction tank includes a support base 1, the middle part of the upper surface of the support base 1 is fixedly connected with a ring-shaped support limit ring 4, and the two sides of the support limit ring 4 are fixedly connected with two symmetrical support limit c...

Embodiment 2

[0032] The raw materials were weighed according to the following formula: 73 parts of methacrylates, 11 parts of acrylates, and 3 parts of emulsifiers.

Embodiment 3

[0034] Weigh the raw materials in parts by weight according to the following formula: 76 parts of methacrylates, 11 parts of acrylates, and 4 parts of emulsifiers.

[0035] Embodiment three:

[0036] Weigh the raw materials in parts by weight according to the following formula: 81 parts of methacrylates, 23 parts of acrylates, and 2 parts of emulsifiers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com