Heat treatment process of hot work die steel

A technology of hot working die steel and process, which is applied in the field of heat treatment of die steel, and can solve the problems of crack hardenability and insufficient impact toughness of die steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

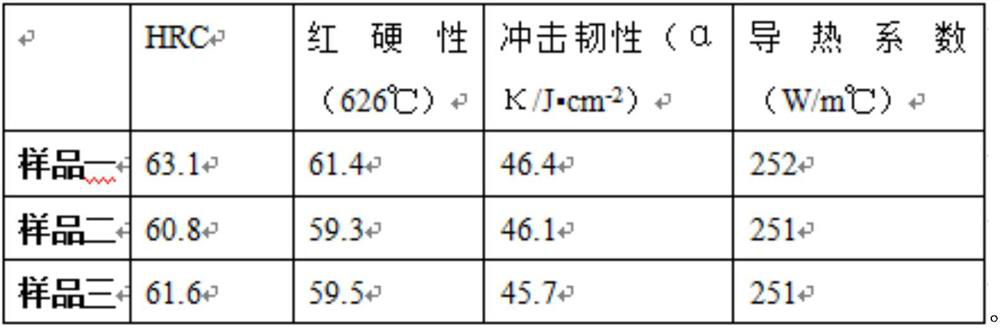

Embodiment 1

[0037] According to the weight percentage of chemical composition, hot work die steel is:

[0038] C: 0.4%, Cr: 2.7%, Mo: 4.2%, W: 5.3%, V: 0.85%, Mn: 0.31%, Ni: 0.75%, Cs: 0.52%, and the balance is Fe and unavoidable impurities.

[0039] The heat treatment process includes the following steps:

[0040] In the first-stage heating and returning step, the temperature is raised to 650°C at a first-stage heating rate of 10°C, and the temperature is lowered to 410°C with the furnace;

[0041] In the second-stage temperature rise and return step, the temperature is raised to 1050°C at the second-stage temperature rise rate of 8°C, and the temperature is lowered to 823°C with the furnace;

[0042] In the third-stage heating and holding step, the temperature is raised to 1142°C at a third-stage heating rate of 6°C and held for 60 minutes;

[0043] Cooling step, maintain the pressure in the furnace at 6bar and cool down to 417°C for 10 minutes, release the pressure and cool to room t...

Embodiment 2

[0050] According to the weight percentage of chemical composition, hot work die steel is:

[0051] C: 0.85%, Cr: 2.6%, Mo: 4.1%, W: 5.2%, V: 0.65%, Mn: 0.35%, Ni: 0.88%, Cs: 0.46%, S: 0.01%, and the balance is Fe and Unavoidable impurities.

[0052] The heat treatment process includes the following steps:

[0053] In the first-stage heating and returning step, the temperature is raised to 660°C at a first-stage heating rate of 12°C, and the temperature is lowered to 415°C with the furnace;

[0054] In the second-stage temperature rise and return step, the temperature is raised to 1060°C at the second-stage temperature rise rate of 7°C, and the temperature is lowered to 823±2°C with the furnace;

[0055] In the third-stage heating and holding step, the temperature is raised to 1143°C at a third-stage heating rate of 5°C and kept for 65 minutes;

[0056] Cooling step, maintain the pressure in the furnace at 6bar and cool down to 417°C for 10 minutes, release the pressure and ...

Embodiment 3

[0061] According to the weight percentage of chemical composition, hot work die steel is:

[0062] C: 0.65%, Cr: 3.3%, Mo: 4.1%, W: 5.5%, V: 0.95%, Mn: 0.33%, Ni: 1.3%, Cs: 0.36%, P: 0.005%, and the balance is Fe and Unavoidable impurities.

[0063] The heat treatment process includes the following steps:

[0064] In the first-stage heating and returning step, the temperature is raised to 650°C at a first-stage heating rate of 10-12°C, and the temperature is lowered to 410°C with the furnace;

[0065] In the second-stage temperature rise and return step, the temperature is raised to 1050°C at a second-stage temperature increase rate of 7-8°C, and the temperature is lowered to 823°C with the furnace;

[0066] In the third-stage heating and holding step, the temperature is raised to 1142°C at a third-stage heating rate of 6°C and held for 60 minutes;

[0067] Cooling step, maintain the pressure in the furnace at 6bar and cool down to 417°C for 10 minutes, release the pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com