780MPa-grade cold-rolled high-strength electro-galvanized steel plate and manufacturing method thereof

A manufacturing method and electro-galvanizing technology, which are applied in the field of steel plate and its manufacturing, can solve the problems of multi-phase structure product instability, low metallurgical cost and process cost, and increased product cost, so as to achieve good promotion prospects and application value, reduce Effect of annealing process cost and metallurgical cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

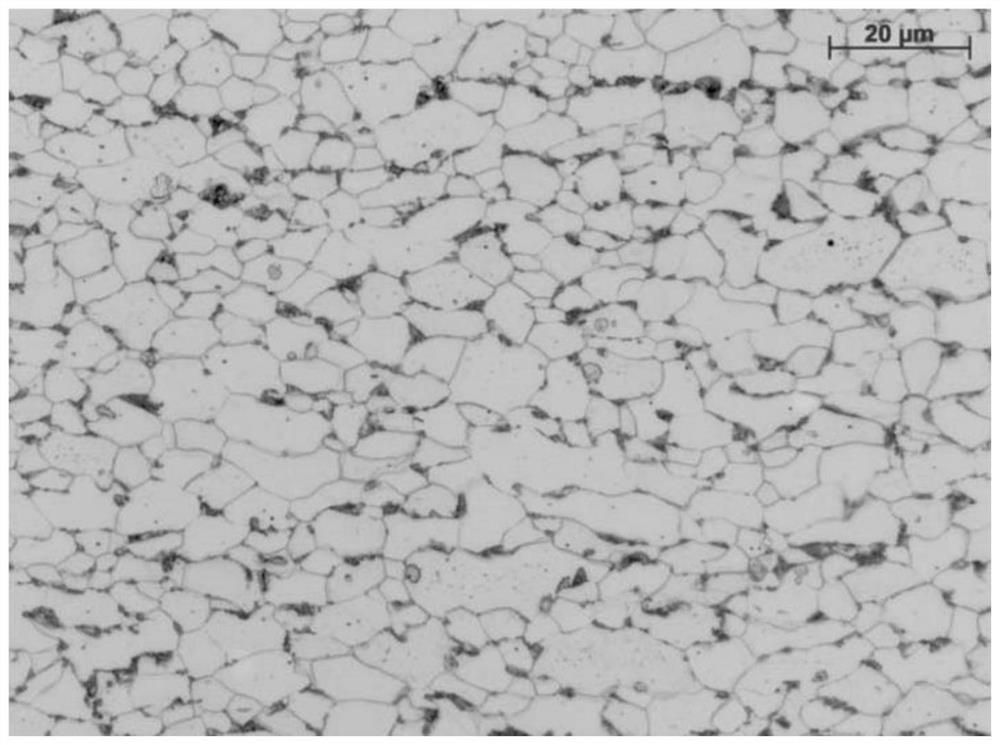

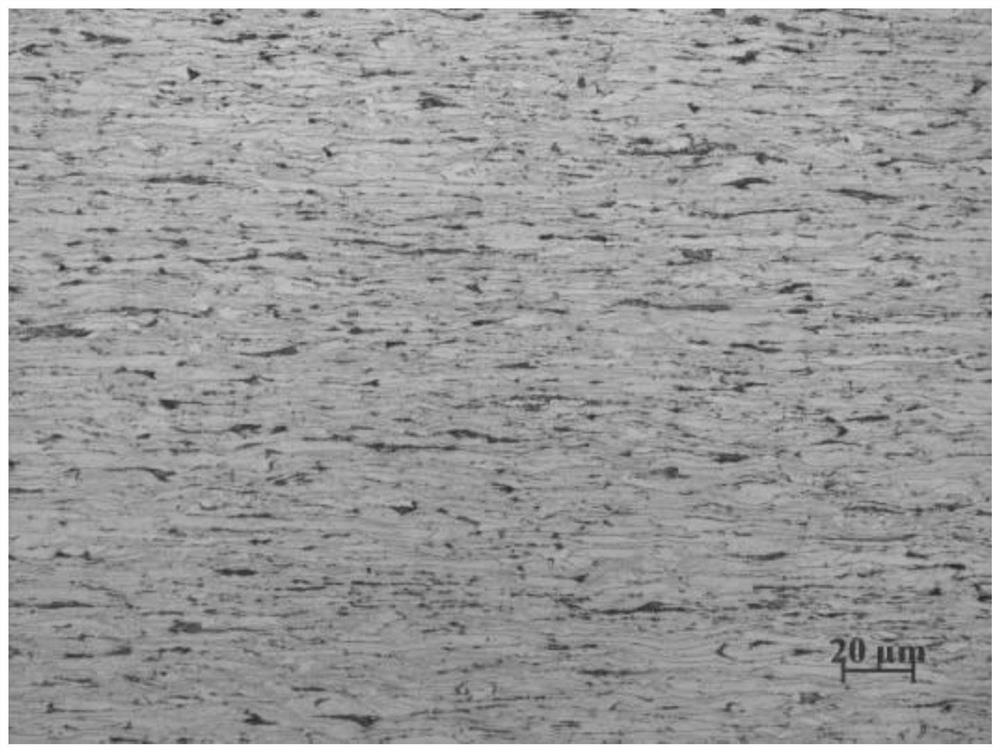

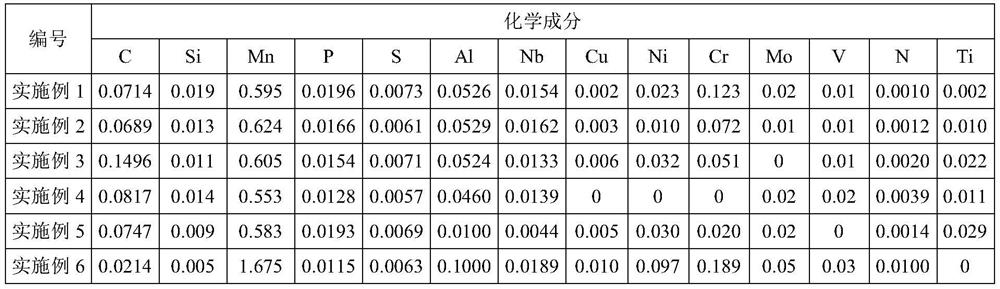

[0075] The 780MPa grade cold-rolled high-strength electrogalvanized steel sheets of Examples 1-6 of the present invention are all prepared by the following steps:

[0076] (1) smelting and casting according to the chemical composition shown in Table 1;

[0077] (2) Hot rolling: control the heating temperature of the slab to 1200-1250°C, and the heating time to 180-240min; ~620°C;

[0078] (3) Pickling and cold rolling: control the total reduction ratio to 65-90%.

[0079] (4) Continuous annealing: the annealing holding temperature is 600-650°C, and the holding time is 60-150s; after the holding is completed, cool at a rate of 10-30°C / s to the aging temperature of 250-400°C.

[0080] (5) Galvanized on the substrate.

[0081] It should be noted that the chemical element composition and related process design of the 780MPa grade cold-rolled high-strength electrogalvanized steel sheets in Examples 1-6 of the present invention all meet the requirements of the design specificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com