Polyether type polyurethane rubber compound with high hardness and high fluidity

A technology of polyether polyurethane and high fluidity, which is applied in the field of polyurethane compound rubber, and can solve problems such as poor dispersion uniformity of compound rubber, increased Mooney viscosity of compound rubber, and product quality defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

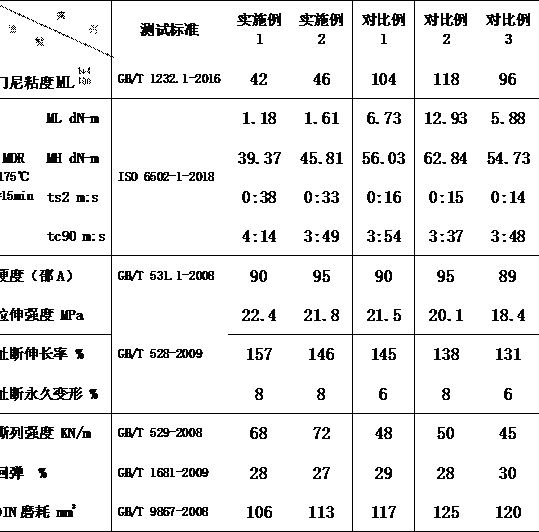

Examples

Embodiment 1

[0019] Parts by mass: polyurethane raw rubber UR101 100, precipitated silica Sil-233 30, stearic acid 0.5, coupling agent A-172 1.2, anti-scorch TMPTMA 12, crosslinking aid ZDMA 1.5, vulcanizing agent DCP40 -SD 3.8;

[0020] According to the above formula, the ingredients were mixed evenly on the open mill, and the tablets were released to measure the vulcanization performance (MDR), the Mooney viscosity of the rubber, and the vulcanization test pieces at 175°C×6min, and the physical properties were tested after parking.

Embodiment 2

[0022] Parts by mass: polyurethane raw rubber UR101 100, precipitated silica Sil-233 40, stearic acid 1, coupling agent A-172 1.5, anti-scorch TMPTMA 15, crosslinking aid ZDMA 2, vulcanizing agent DCP40 -SD 3.8;

[0023] According to the above formula, the ingredients were mixed evenly on the open mill, and the tablets were released to measure the vulcanization performance (MDR), the Mooney viscosity of the rubber, and the vulcanization test pieces at 175°C×6min, and the physical properties were tested after parking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com