Self-balancing type anti-vibration spin dryer tube for impeller type washing machine

A pulsator washing machine, self-balancing technology, applied to other washing machines, washing machines with containers, dryers, etc., can solve the problems of large damage to the washing machine, noise of the drying bucket, deceleration of the drying bucket, etc., and improve the dehydration efficiency , prolong the service life, and stabilize the rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

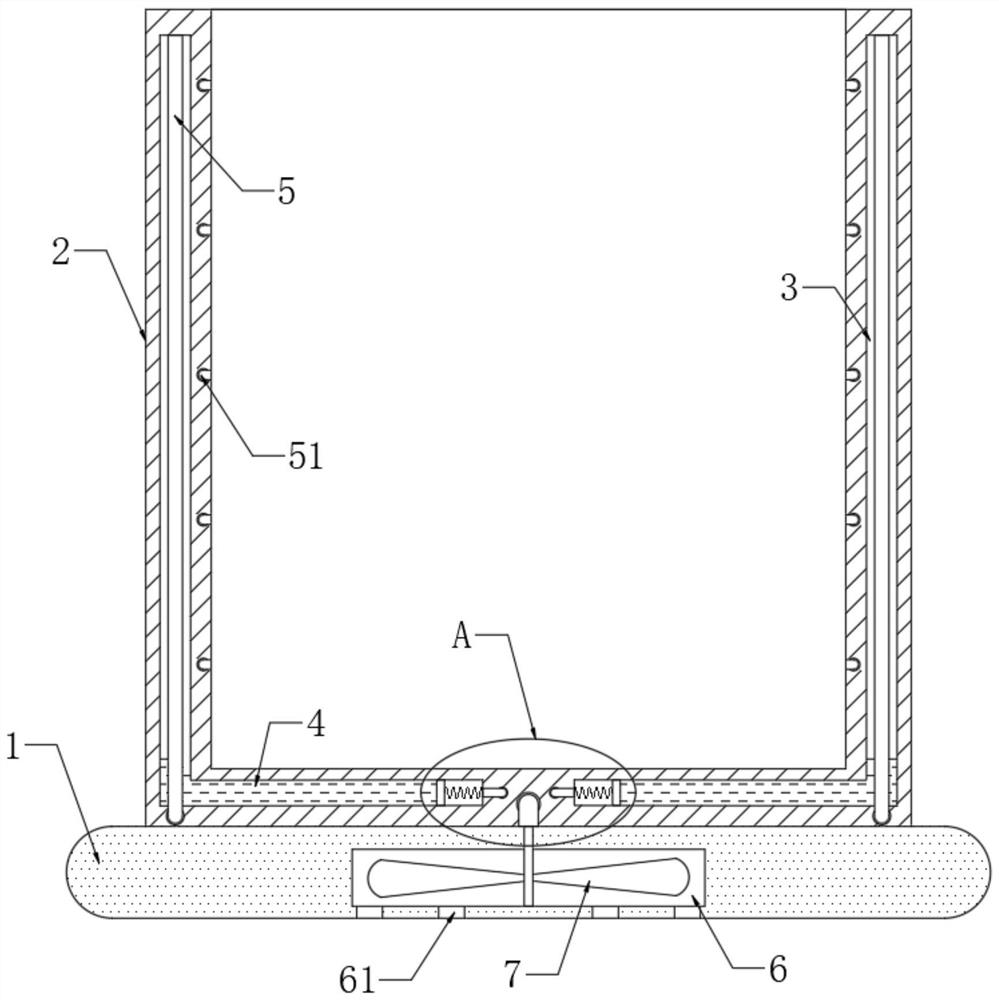

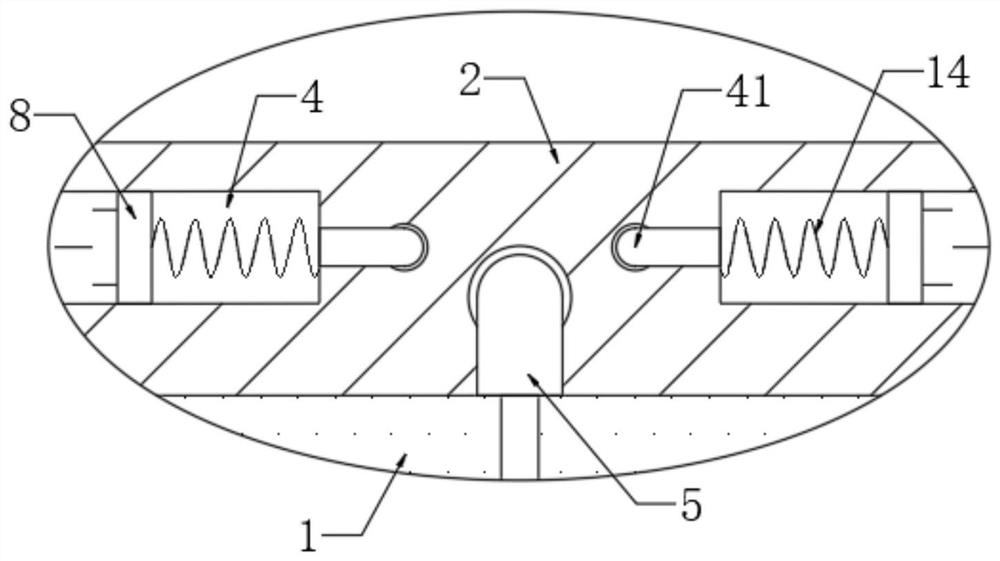

[0023] refer to Figure 1-2 , a self-balancing anti-vibration drying barrel for a pulsator washing machine, comprising a base 1, the upper end of the base 1 is rotatably connected to a barrel body 2, the side wall of the barrel body 2 is provided with a plurality of balance chambers 3, and the barrel body 2 The side wall is also provided with a plurality of liquid storage chambers 4 communicating with the balance chamber 3, and the liquid storage chambers 4 are filled with counterweight liquid. Specifically, the counterweight liquid is water, and other liquids with higher density can also be used, which can effectively Balance barrel 2 and get final product. The side wall of the base 1 is provided with an exhaust groove 6, a slide plug 8 is sealed and slidably connected in the liquid storage chamber 4, a driving device for driving the flow of the counterweight liquid is installed in the exhaust groove 6, and a device with The exhaust pipe 41 communicated with the liquid stora...

Embodiment 2

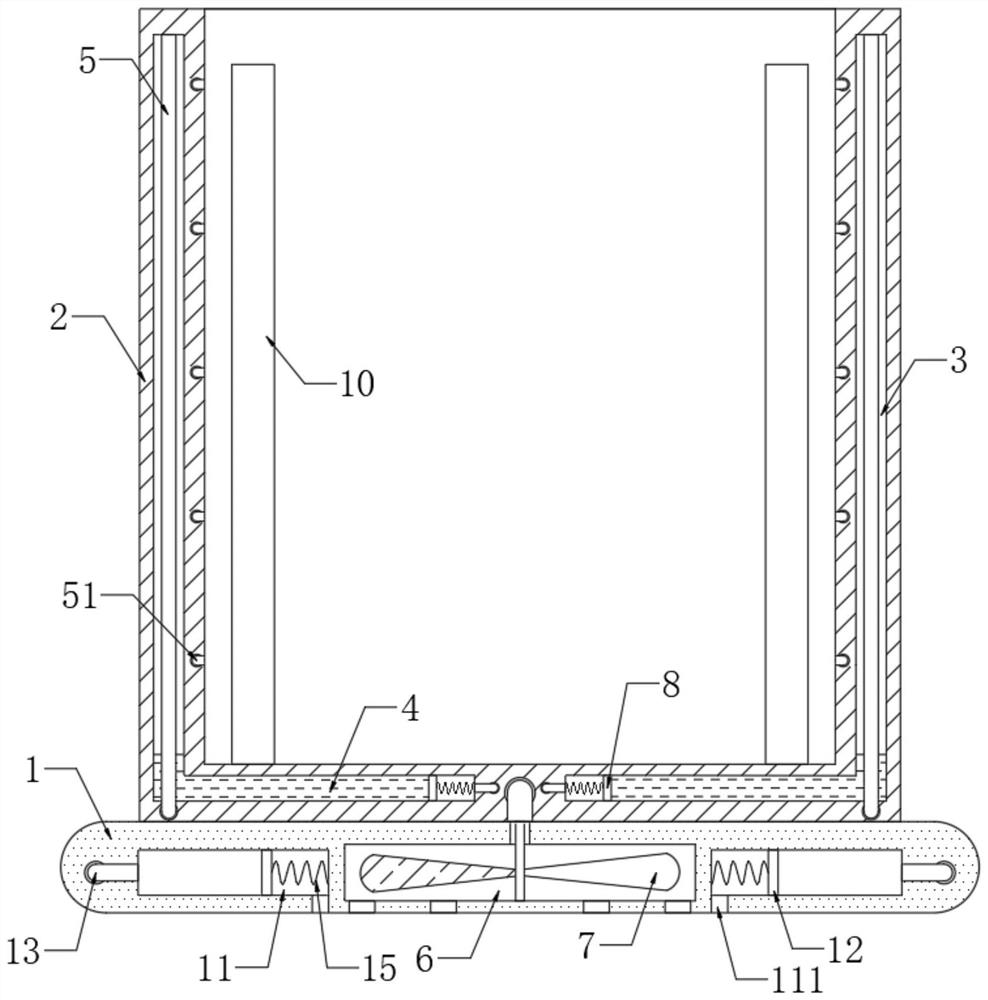

[0028] refer to Figure 3-4 , different from Embodiment 1, the inner bottom of barrel body 2 is slidably connected with a plurality of pressure plates 10, and a bellows 9 is fixedly connected between every two adjacent pressure plates 10. It should be noted that the bellows 9 is arranged on At the higher position of the pressing plate 10, in order to prevent the washing and drying of the clothes from causing obstacles, the side wall of the base 1 is provided with a chute 11, and a telescopic device for making the bellows 9 stretch is installed in the chute 11, and the telescopic device includes a sealing Slidingly connected to the iron slider 12 in the chute 11, and the iron slider 12 is elastically connected on the inner wall of the chute 11 through the telescopic spring 15, and the inner bottom of the chute 11 is provided with an exhaust hole 111, by setting the exhaust The hole 111 is not hindered by the air when the iron slide block 12 moves back and forth conveniently. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com