Construction method of super-large-diameter anchoring body

A technology with super large diameter and construction method, which is applied in earthwork drilling, installation of bolts, mining equipment, etc., can solve the problems of insufficient bearing capacity of anchor cables, complex structure, and unclean cleaning of soil and slag in the hole, so as to reduce the hole wall. The effect of collapse risk, flexible processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] see Figure 1-5 , the present invention provides the following technical solutions: a construction method for super-large-diameter anchors, comprising the following steps:

[0034] S1. The symmetrical steel plate of the casing boot is protruded out;

[0035] S2, rotary soil cutting drilling;

[0036] S3, casing follow-up;

[0037] S4, high pressure water reverse slag;

[0038] S5, super large diameter hole forming;

[0039] S6. Manufacture and installation of anchor rod body;

[0040] S7. Grouting for full length hole section;

[0041] S8, super large diameter anchor body is formed.

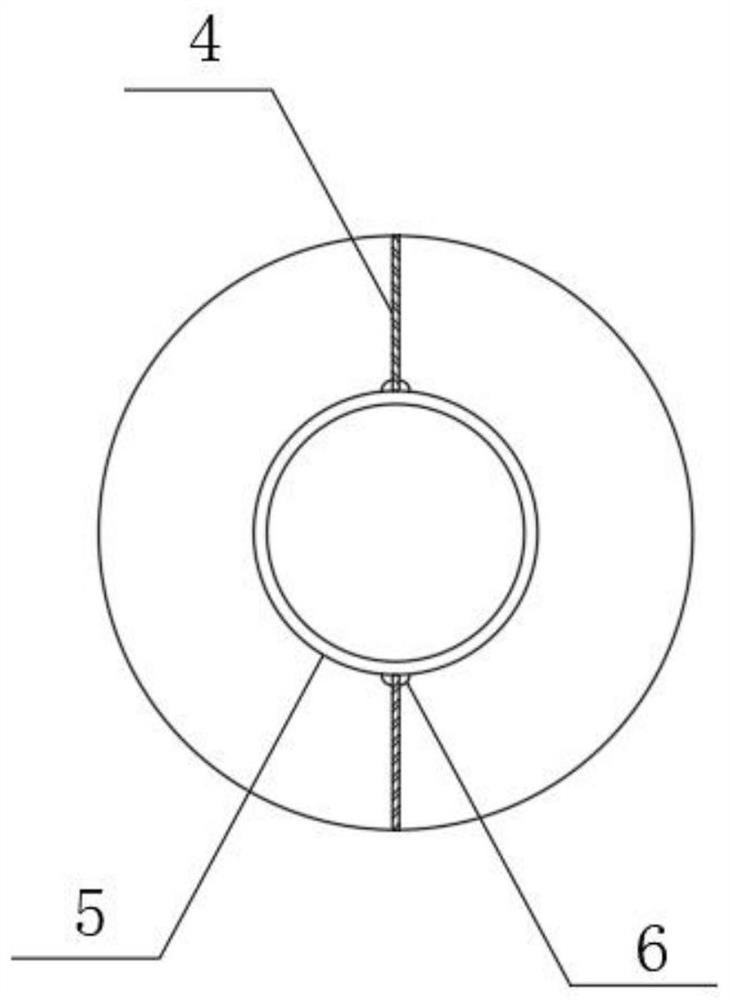

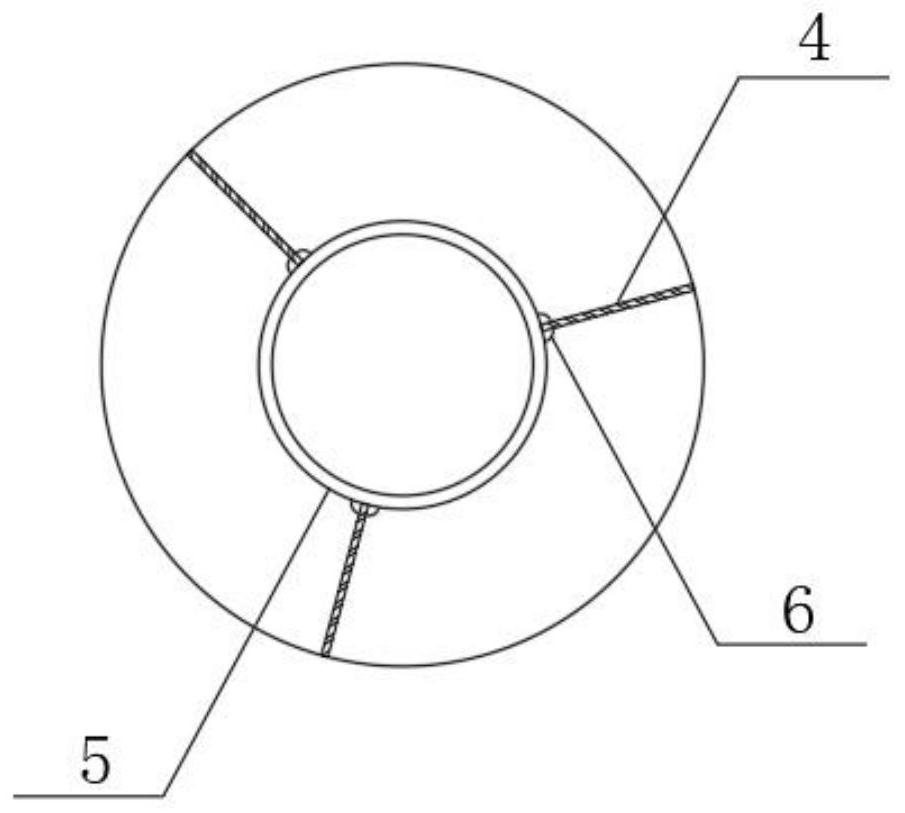

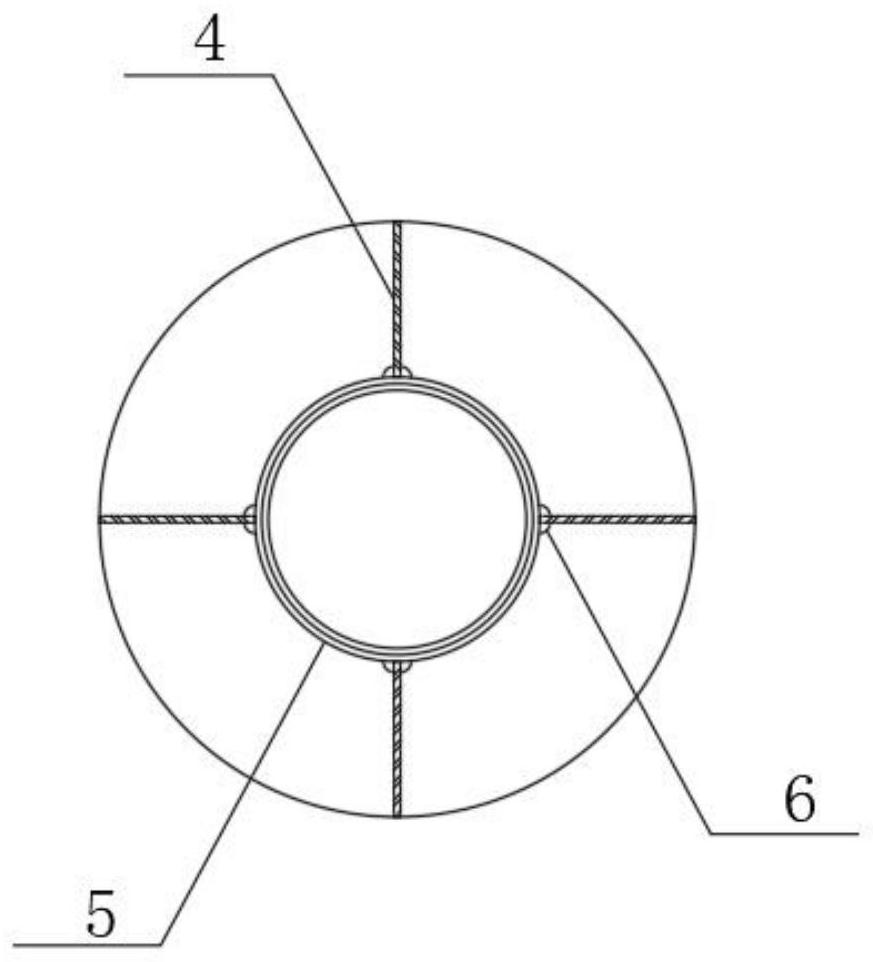

[0042] Specifically, in step S1, the casing shoe 1 produced by the symmetrical steel plate protruding is installed on the front end of the casing 2, the steel plate 4 is flush and symmetrically welded with the casing shoe 3 with the axis of the casing 2 as the center line, and the casing 2 is pulled by the motor Rotate, the steel plate 4 is rotated to cut the soil, the hole is clear...

Embodiment 2

[0050] see Figure 1-5 , the present invention provides the following technical solutions: a construction method for super-large-diameter anchors, comprising the following steps:

[0051] S1. The symmetrical steel plate of the casing boot is protruded out;

[0052] S2, rotary soil cutting drilling;

[0053] S3, casing follow-up;

[0054] S4, high pressure water reverse slag;

[0055] S5, super large diameter hole forming;

[0056] S6. Manufacture and installation of anchor rod body;

[0057] S7. Grouting for full length hole section;

[0058] S8, super large diameter anchor body is formed.

[0059] Specifically, in step S1, the casing shoe 1 produced by the symmetrical steel plate protruding is installed on the front end of the casing 2, the steel plate 4 is flush and symmetrically welded with the casing shoe 3 with the axis of the casing 2 as the center line, and the casing 2 is pulled by the motor Rotate, the steel plate 4 is rotated to cut the soil, the hole is clear...

Embodiment 3

[0067] see Figure 1-5 , the present invention provides the following technical solutions: a construction method for super-large-diameter anchors, comprising the following steps:

[0068] S1. The symmetrical steel plate of the casing boot is protruded out;

[0069] S2, rotary soil cutting drilling;

[0070] S3, casing follow-up;

[0071] S4, high pressure water reverse slag;

[0072] S5, super large diameter hole forming;

[0073] S6. Manufacture and installation of anchor rod body;

[0074] S7. Grouting for full length hole section;

[0075] S8, super large diameter anchor body is formed.

[0076] Specifically, in step S1, the casing shoe 1 produced by the symmetrical steel plate protruding is installed on the front end of the casing 2, the steel plate 4 is flush and symmetrically welded with the casing shoe 3 with the axis of the casing 2 as the center line, and the casing 2 is pulled by the motor Rotate, the steel plate 4 is rotated to cut the soil, the hole is cleared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com