Wind turbine generator heat dissipation assembly cleaning device

A heat dissipation component and cleaning device technology, which is applied in wind power generation, wind turbines, engines, etc., can solve problems such as clogging the filter screen, not being able to get water, and narrow spaces between gaps, so as to protect electrical components, ensure cleaning efficiency, and ensure practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

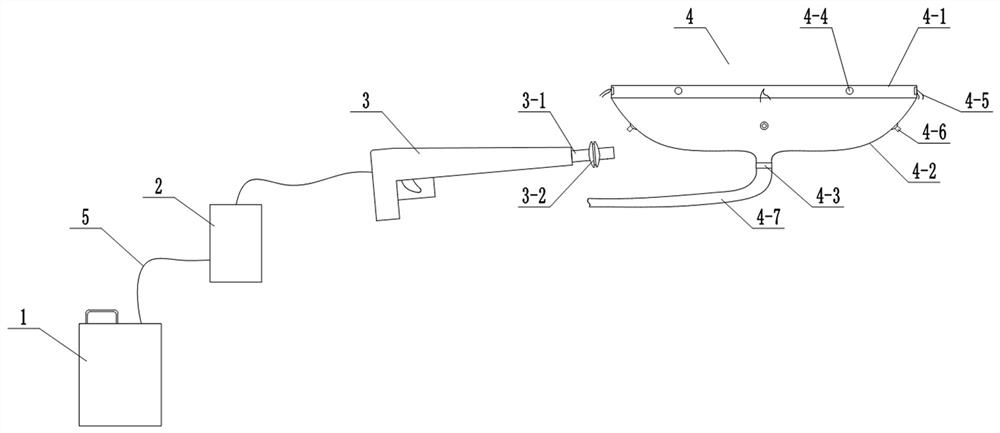

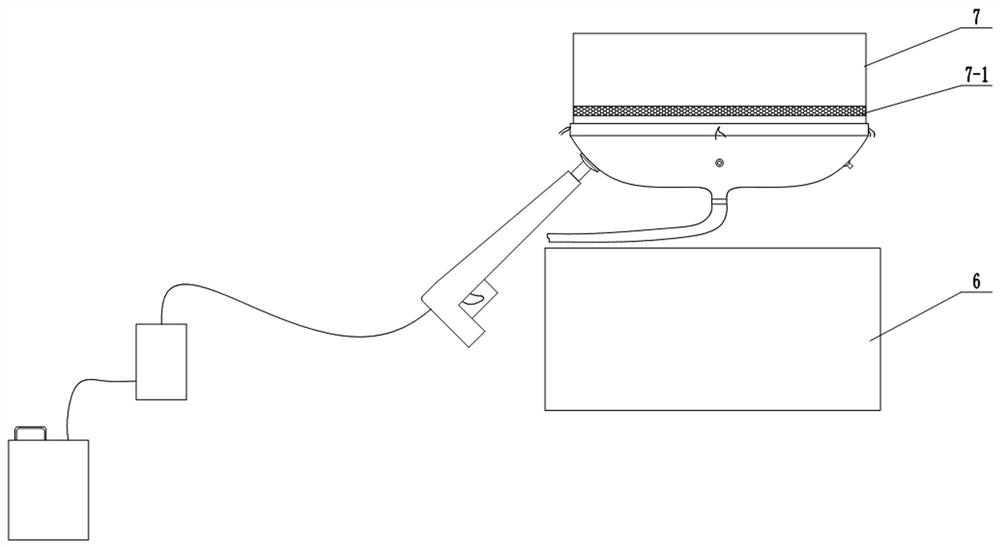

[0016] like Figure 1-Figure 2 As shown, the present invention provides a cleaning device for the heat dissipation component 7 of the wind turbine 6 , which includes a water tank 1 , a water pump 2 , a water gun 3 and a cleaning cover 4 .

[0017] The water tank 1 is connected to the water inlet of the water pump 2 through the pipeline 5, and the water outlet 4-3 of the water pump 2 is connected to the water gun 3 through the pipeline 5, and the water gun 3 includes a water spray pipe 3-1 for drainage.

[0018] The cleaning cover 4 is used to prevent the waste water from splashing during the cleaning process of the filter screen 7-1, and it includes a fixed port 4-1 for fixed connection with the bottom of the heat dissipation assembly 7, which is connected at the bottom of the fixed port 4-1. There is a conical cylinder 4-2, the bottom of the conical cylinder 4-2 is provided with a water outlet 4-3, the fixed port 4-1, and the conical cylinder 4-2 are made of good elasticity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com