Micro-flow plane sealing giant magnetostrictive proportional valve

A giant magnetostrictive, flat sealing technology, applied in valve details, valve device, valve operation/release device, etc., can solve the deformation of piezoelectric ceramics, small output force, increase the thickness and quantity of piezoelectric ceramics , Increase the volume and weight of the valve, and achieve the effect of reducing the difficulty of manufacturing, wide adjustment range and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

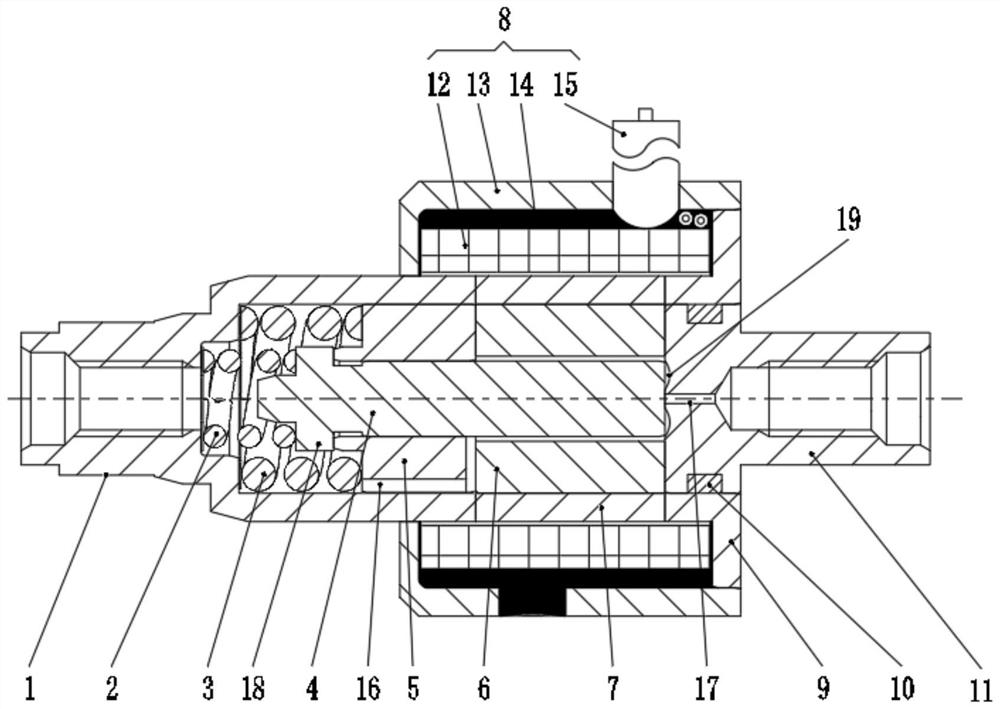

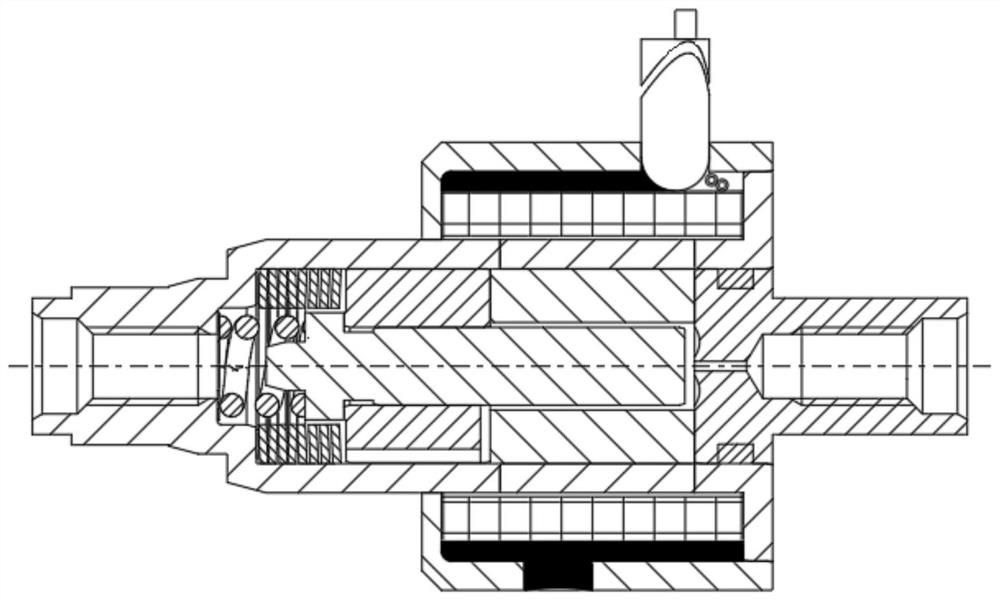

[0023] Such as figure 1 Shown is the structural representation of the present invention:

[0024] The present invention provides a micro-flow planar sealing giant magnetostrictive proportional valve, which includes a valve body 1, a valve core 4, a magnetic isolation ring 7, and a pole shoe 9. The valve body 1, magnetic isolation ring 7, and pole shoe 9 are From left to right, they are fixedly connected in turn. The magnetic isolation ring 7 is covered with a coil assembly 8, the valve body 1 is provided with a fluid inlet, the inner hole of the pole shoe 9 is provided with a valve seat 11, and the valve seat 11 is provided with a valve nozzle channel 17. , the valve core 4 is arranged on the left side of the valve seat 11, the face of the valve core 4 and the valve seat 11 facing each other is a flat sealing surface, the left end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com