Glass measuring vessel capacity automatic calibrating device and calibrating method thereof

A glass measuring device and verification device technology, applied in measuring devices, testing/calibration devices, instruments, etc., can solve the problems of non-repetitiveness, high labor intensity, and high error risk, avoiding human errors and reducing labor costs. , the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

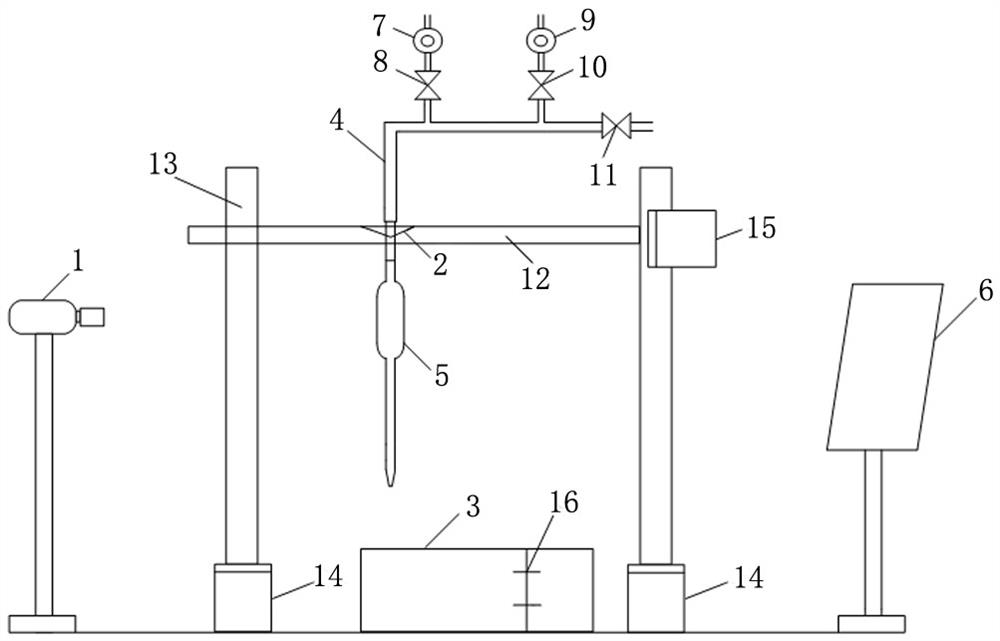

[0043] A typical embodiment of the present invention provides an automatic capacity verification device for glass measuring vessels, including a host computer, an image acquisition device 1 , a gas control pipeline, a jacking mechanism, a translation mechanism, a measuring vessel fixing fixture 2 and a water tank 3 .

[0044] Such as figure 1 As shown, the measuring device fixing jig 2 is connected with the jacking mechanism and the translation mechanism, the lifting mechanism drives the measuring device fixing jig 2 to move vertically, and the translation mechanism drives the measuring device fixing jig 2 to move laterally ; The water tank 3 is arranged below the fixture 2 of the measuring device.

[0045] The gas control pipeline includes a connection hose 4, a water suction assembly and a water discharge assembly. The connection hose has a front port, an end port, a water suction interface and a water discharge interface. The water suction interface and the water discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com