Preparation method of geological slice sample for TEM analysis

A technology for thin slices and samples, applied in the field of preparation of transmission electron microscope samples, can solve problems such as direct damage, crystal amorphization, cracks, etc., to achieve the effect of increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

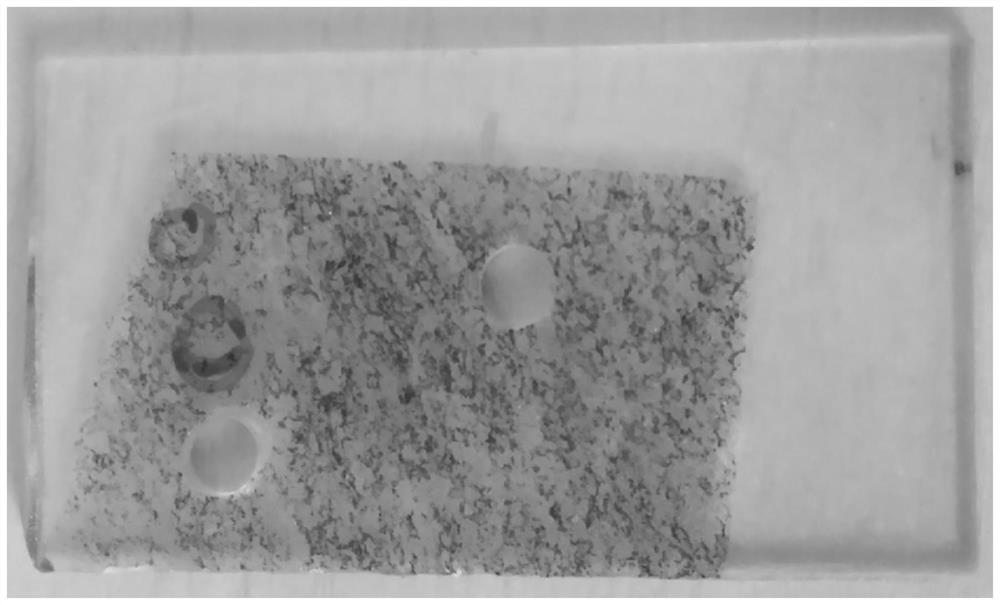

Image

Examples

Embodiment 1

[0041] (1) Prepare the thin section: apply a layer of epoxy resin glue evenly on one surface of the glass slide, select the rock sample and fix it on the glass slide with epoxy resin glue, and obtain a glass slide layer, a glue layer and a rock sample. Layer-structured flakes;

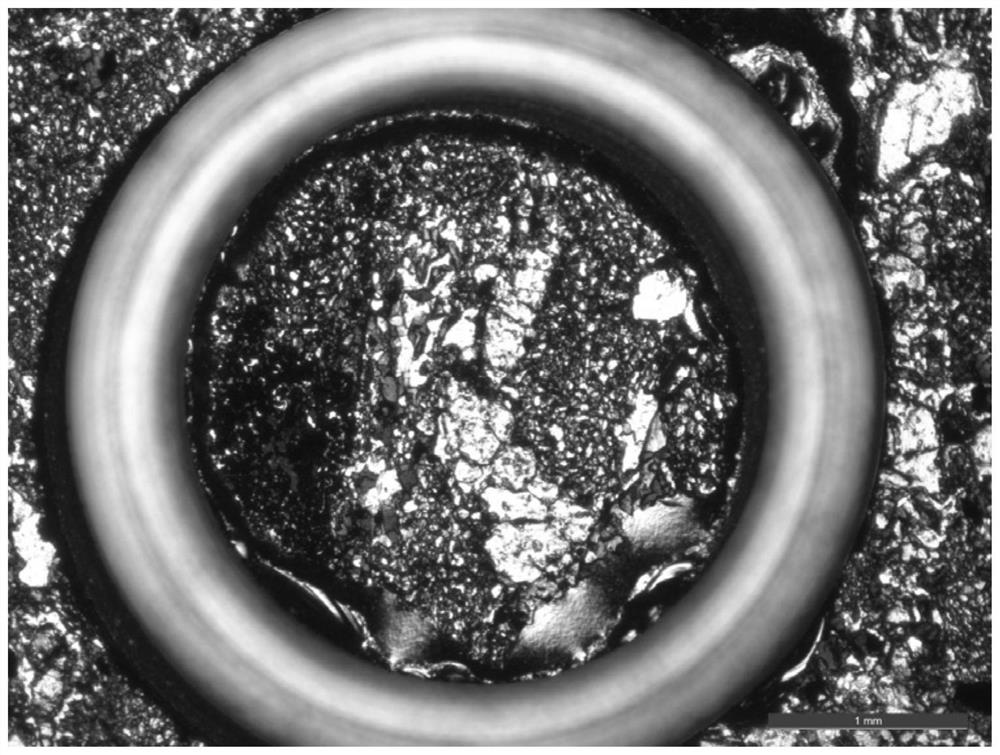

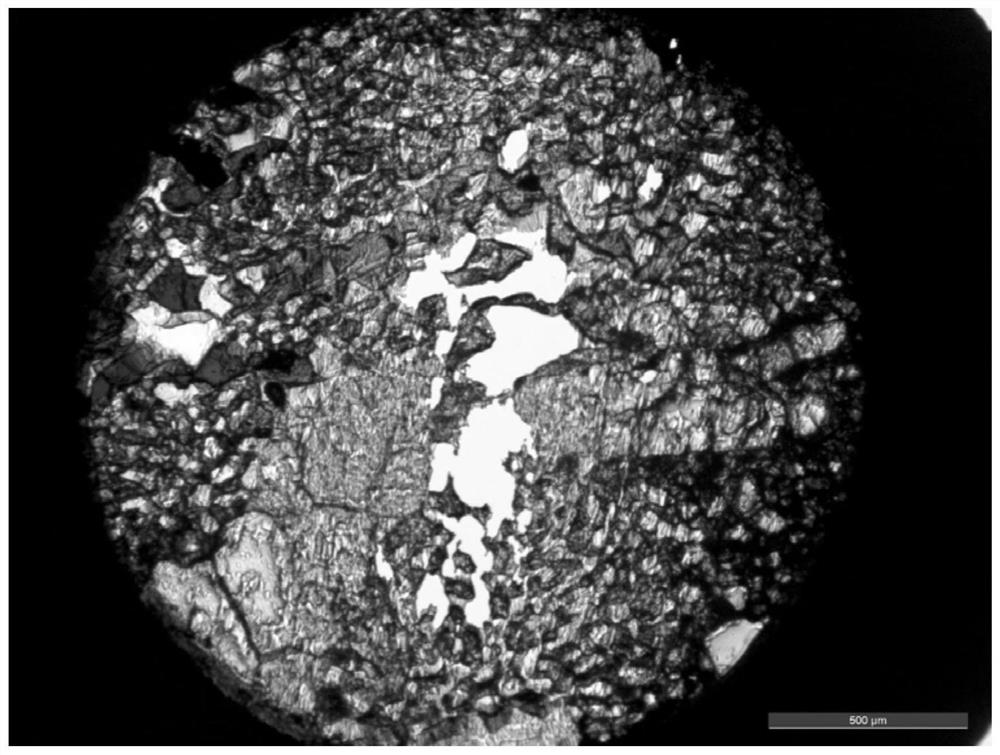

[0042] (2) Select analysis area: Utilize optical microscope to observe the thin section of step (1) gained, select the area (i.e. analysis area) that needs to be analyzed with TEM, and draw a circle with a marker pen to mark, the diameter of circle is 3mm, in the light microscope Conoscopic mode, adjust the size of the aperture to ensure that the analysis area is in the center of the circle;

[0043] (3) Fixed sheet: place Place the fixing pins together with the base on the heating platform for heating, and place an empty base on the cooling platform. The temperature of the heating platform is set at 130 ° C. Wait for 3-5 minutes, apply paraffin evenly on the fixing pins, and then place the fixing pi...

Embodiment 2

[0048] (1) Prepare the thin section: apply a layer of 502 glue evenly on one surface of the glass slide, select the rock sample and fix it on the glass slide through the 502 glue layer, and obtain a film with the structure of the glass slide layer, the glue layer and the rock sample layer. flakes;

[0049] (2) Select analysis area: Utilize optical microscope to observe the thin section of step (1) gained, select the area (i.e. analysis area) that needs to be analyzed with TEM, and draw a circle with a marker pen to mark, the diameter of circle is 3mm, in the light microscope Conoscopic mode, adjust the size of the aperture, and the analysis area is in the center of the circle;

[0050] (3) Fixed sheet: place Place the fixing pins together with the base on the heating platform for heating, and place an empty base on the cooling platform. The temperature of the heating platform is set at 130 ° C. Wait for 3-5 minutes, apply paraffin evenly on the fixing pins, and then place th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com