A cable continuity test system

A technology of on-off testing and cables, which is applied in the field of cable on-off testing systems, can solve the problems of inconvenient wire placement, poor fixing effect of wire ends, poor protection effect, etc., to achieve convenient storage, prolong service life, and increase use functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

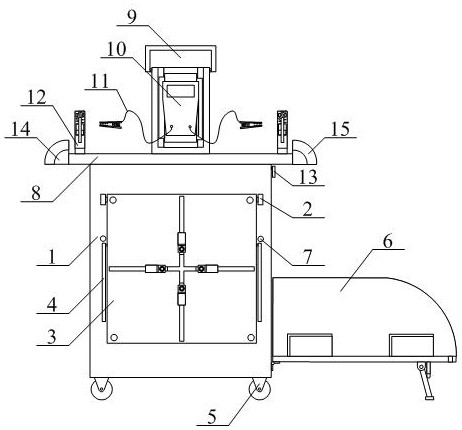

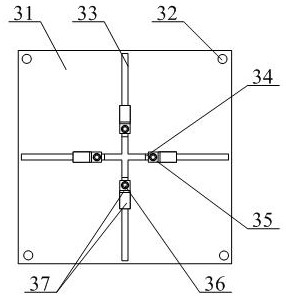

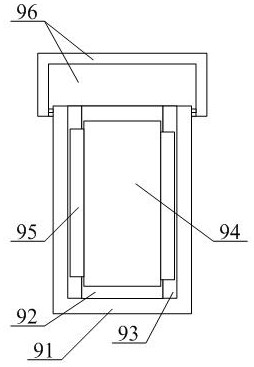

[0033] as attached figure 1 and attached figure 2As shown, a cable continuity test system includes a housing 1, an ear plate 2, a wire placement frame structure 3, a support rod 4, a moving wheel 5, a tool placement frame structure 6, a positioning hole 7, a workbench 8, and a work protection frame Structure 9, multimeter 10, test pen 11, wire end fixing frame structure 12, baffle 13, wire support frame 14 and arc groove 15, the lug plate 2 is welded on the left and right sides of the upper front end of the shell 1 respectively; The wire placement frame structure 3 is installed on the inner lower part of the ear plate 2; the support rods 4 are respectively arranged on the left and right sides of the wire placement frame structure 3; the moving wheels 5 are respectively bolted to the lower part of the housing 1 Four corner positions; the tool placement rack structure 6 is installed on the right side of the casing 1; the positioning holes 7 are respectively opened on the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com