XL power distribution box with good protection performance

A power distribution box, protective technology, applied in the substation/distribution device casing, electrical components, substation/switch layout details, etc. There are no problems such as setting buffer devices, so as to achieve good buffering and protection effects, good heat dissipation effects, and reduce heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

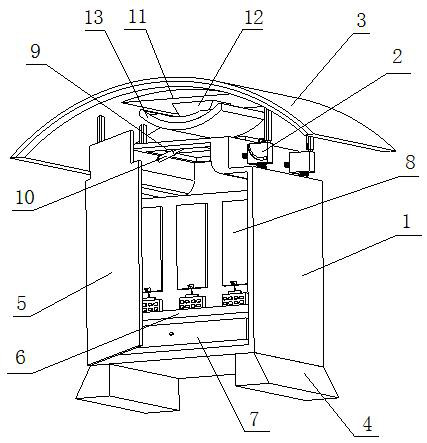

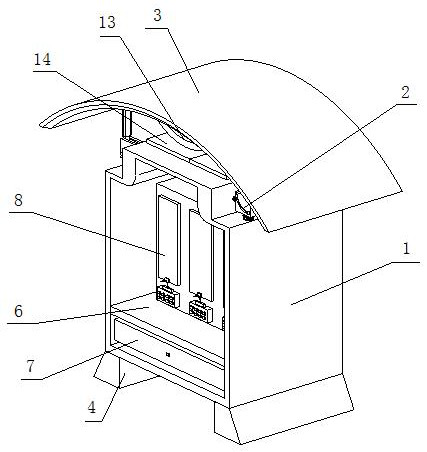

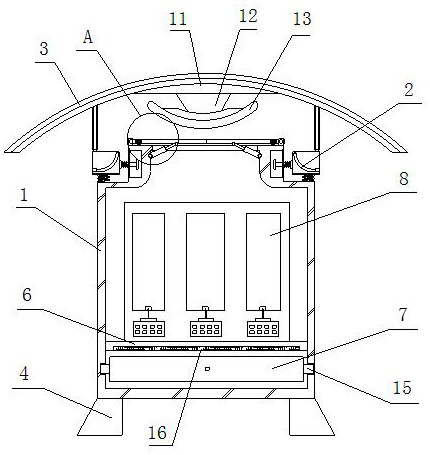

[0027] see Figure 1-4 , the present invention provides a technical solution: an XL power distribution box with good protection, including a box body 1 and a buffer protection device 2, the top outer wall of the box body 1 is fixedly connected with a buffer protection device 2, and the buffer protection device 2 The top is fixedly connected with a protective shed 3, the outer wall of the bottom of the box body 1 is fixedly connected with two abutments 4, one side of the box body 1 is hinged with a box door 5, and the inner wall of one side of the box body 1 is fixedly connected with an isolation plate 6. The inner wall of the body 1 is slidingly connected with the insulation box 7 under the isolation plate 6, the component board 8 is fixedly installed on the top of the isolation plate 6, the top of the box body 1 is provided with a heat dissipation port 9, and the inner wall of one side of the box body 1 is hinged. There is a hydraulic cylinder 10, the bottom of the protective...

Embodiment 2

[0030] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the buffer protection device 2 includes a support rod 201, the outer wall of one side of the support rod 201 is fixedly connected with an H-shaped column 202, and the top outer wall of the box body 1 is fixed A buffer spring 204 is connected, the top of the buffer spring 204 is fixedly connected with a moving block 205, and the top of the moving block 205 is slidably connected with a connecting frame 206, and the outer wall of one side of the connecting frame 206 is fixedly connected with a moving bar 203, and one side of the connecting frame 206 An arc-shaped groove 207 is provided, and a buffer rod 208 is fixedly connected to the side of the moving rod 203 far away from the support rod 201. The spring 210 is provided with a buffer groove 211 inside the box body 1 .

[0031] In this embodiment, through the buffer protection device 2 provided, it is convenien...

Embodiment 3

[0033] Such as Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the insulation box 7 is made of polyurethane board, the interior of the insulation box 7 is provided with cooling liquid, and the top of the insulation box 7 is opened There is a vent, one side of the heat preservation box 7 is fixedly connected with a handle, the interior of the moisture-proof plate 16 is provided with calcium chloride particles, one side of the adjustment plate 14 is hinged with the top outer wall of the box body 1, and the size of the adjustment plate 14 is larger than the heat dissipation The size of the mouth 9, the bottom of the tension spring 18 is movably connected with the top outer wall of the box body 1, and the side inner wall of the box body 1 is provided with a slide groove that is slidably connected with the sliding block 15, and the top of the support rod 201 is connected with the top of the protective shed 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com