Automatic wire changing device for electric-arc fuse metal printer

A metal and automatic technology, which is applied in the direction of electrode support devices, arc welding equipment, metal processing equipment, etc., can solve the problems of single, unrealized multi-metal composite material additive manufacturing, and limited product manufacturing capabilities, so as to achieve strong feasibility, Excellent mechanical properties and physical and chemical properties, clear and clear effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

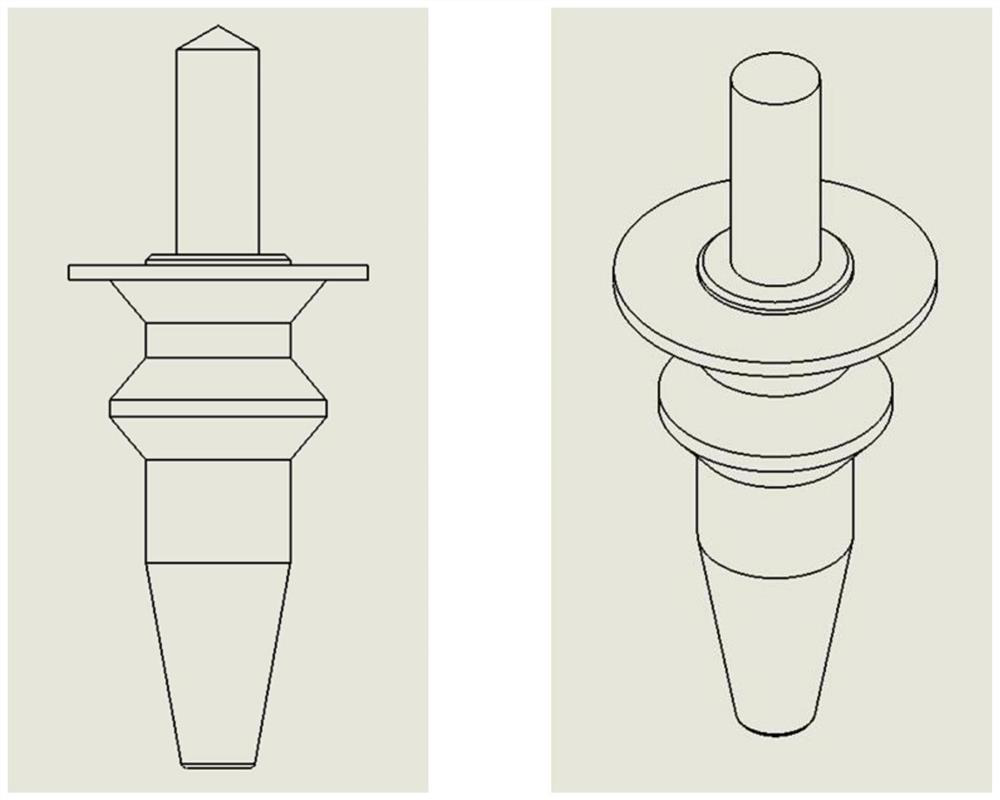

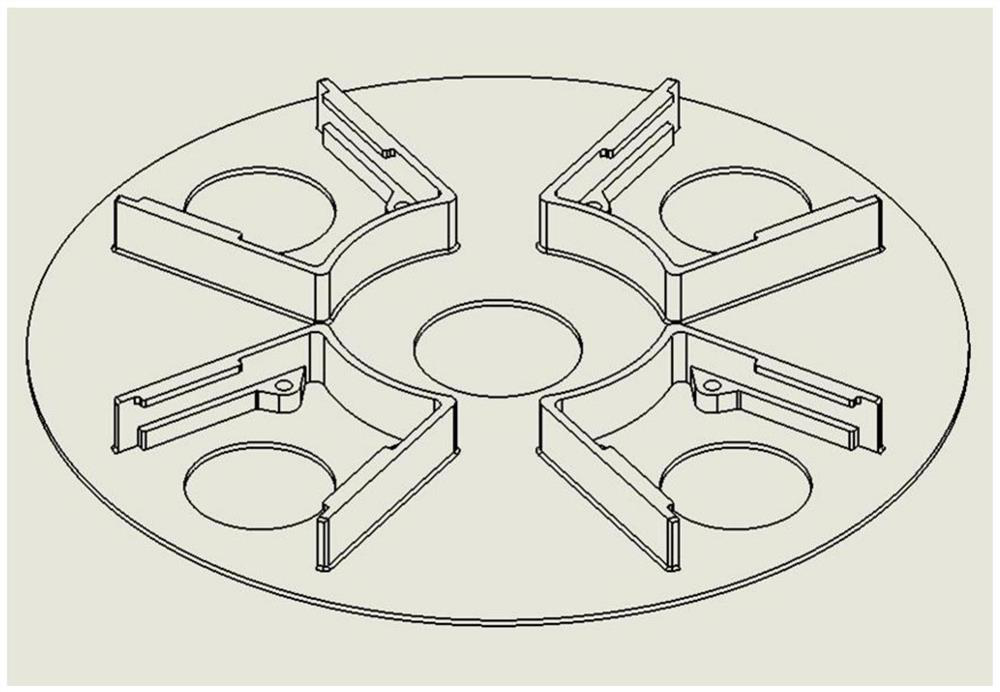

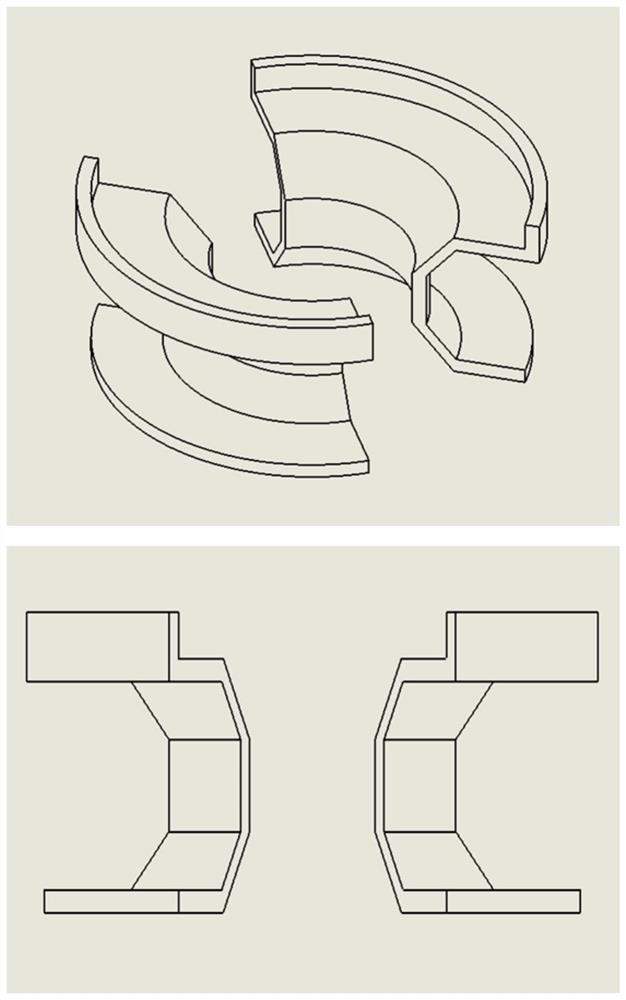

[0015] Such as Figure 5 As shown, the present invention includes 4 metal nozzles (1), a nozzle platform (2), 4 nozzle clamping parts (3) and 4 pairs of customized plate springs, which are installed together to form a nozzle group as shown in the figure. Among them, the nozzle located in the upper right corner has been pressed down to enter the working state, which belongs to the working nozzle, while the other three nozzles are clamped by the clamping parts and are in the suspended state. The overall printing process is as follows: First, computer modeling is carried out. After the modeling is completed, the computer analyzes the model data as numerical control data and transmits it to the numerical control system. Control the print head group designed emphatically in the present invention to move in the X and Y axis directions, so as to complete the printing process step by step.

[0016] In the printing process of products with 4 kinds of metal raw materials, the specific ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap